Manufacturing method for double polylactic acid (PLA) laminated paper cup

A manufacturing method and technology of coated paper, applied in the direction of cardboard articles, etc., can solve a lot of problems such as manpower and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] S1, choose 200g of pure PLA (granule) on the market, water 2000g, mix PLA (granule) with pure water, make mixed liquid;

[0033] S2. Stir the mixed liquid prepared in step S1 at a stirring speed of 45 r / min for 8-12 hours to obtain liquid 6;

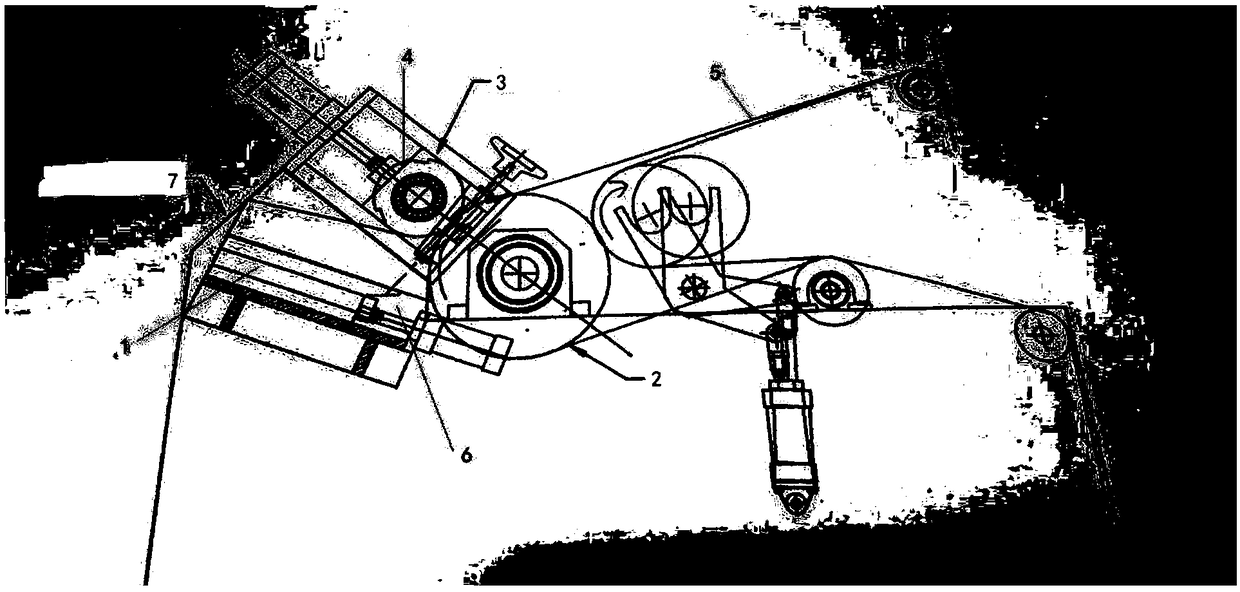

[0034] S3. Pour the liquid 6 prepared in step S2 into the heating tank 1. The heating tank 1 is set in the PE rubber baffle 7. The temperature of the heating tank 1 is controlled at 200-210°C. The rubber wheel 2 stirs and rolls up a layer of PLA. The temperature of the rubber wheel 2 is controlled at 190-200°C. The comma scraper 3 set on the side of the rubber wheel 2 scrapes the PLA rolled up by the rubber wheel 2 to a thickness of 0.20 -60μ, the pressure roller 4 presses the paper until it sticks to the adhesive roller 2. At this time, the PLA rolled up by the adhesive roller 2 is coated with the paper (intermolecular connection), and finally the PLA is coated by the self-rotating wheel. Take away the paper to make PLA-coated p...

Embodiment 2

[0047] S1, choose 400g of pure PLA (granular) on the market, water 4000g, mix PLA (granular) with pure water, make mixed liquid;

[0048] S2. Stir the mixed liquid prepared in step S1 at a stirring speed of 50 r / min for 8-10 hours to obtain liquid 6;

[0049] S3. Pour the liquid 6 prepared in step S2 into the heating tank 1. The temperature of the heating tank 1 is controlled at 200-210°C. Stir and roll up a layer of PLA through the adhesive wheel 2 arranged above the heating tank 1. The temperature of the rubber wheel 2 is controlled at 190-200°C. The comma scraper 3 set on one side of the rubber wheel 2 scrapes the PLA rolled up by the rubber wheel 2 to a thickness of 0.20-60 μ, and the pressure wheel 4 presses the paper to the thickness of the back. The rubber wheel 2 is pasted together. At this time, the PLA rolled up by the rubber wheel 2 is coated with the paper (intermolecular connection), and finally the paper that has been coated with PLA is taken away by the self-rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com