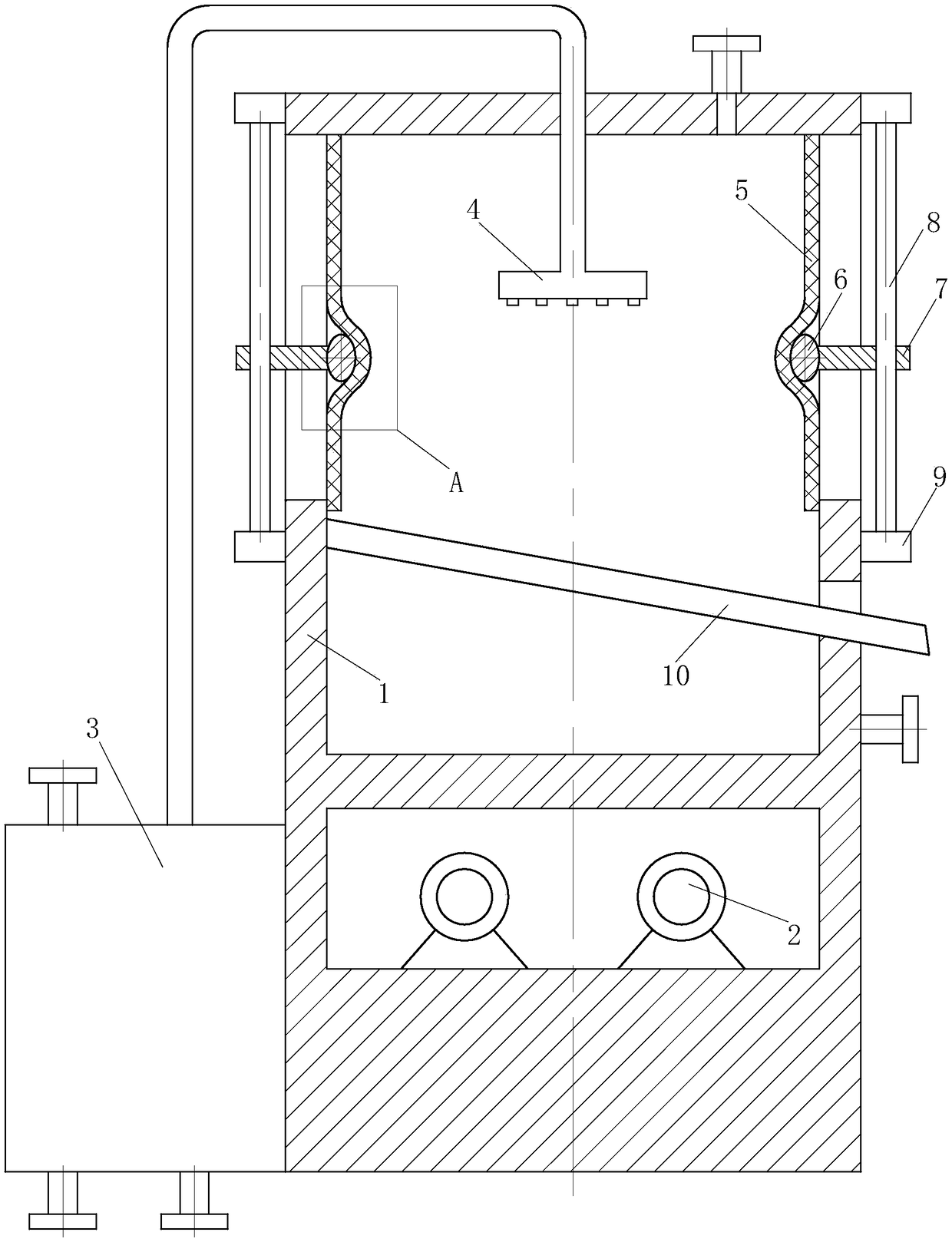

Industrial-high-salinity-wastewater desalting system

A high-salt, industrial technology, applied in general water supply conservation, alkali metal chloride, water/sewage treatment, etc., can solve the problems affecting the use of desalination devices, inconvenient manual cleaning, etc. The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

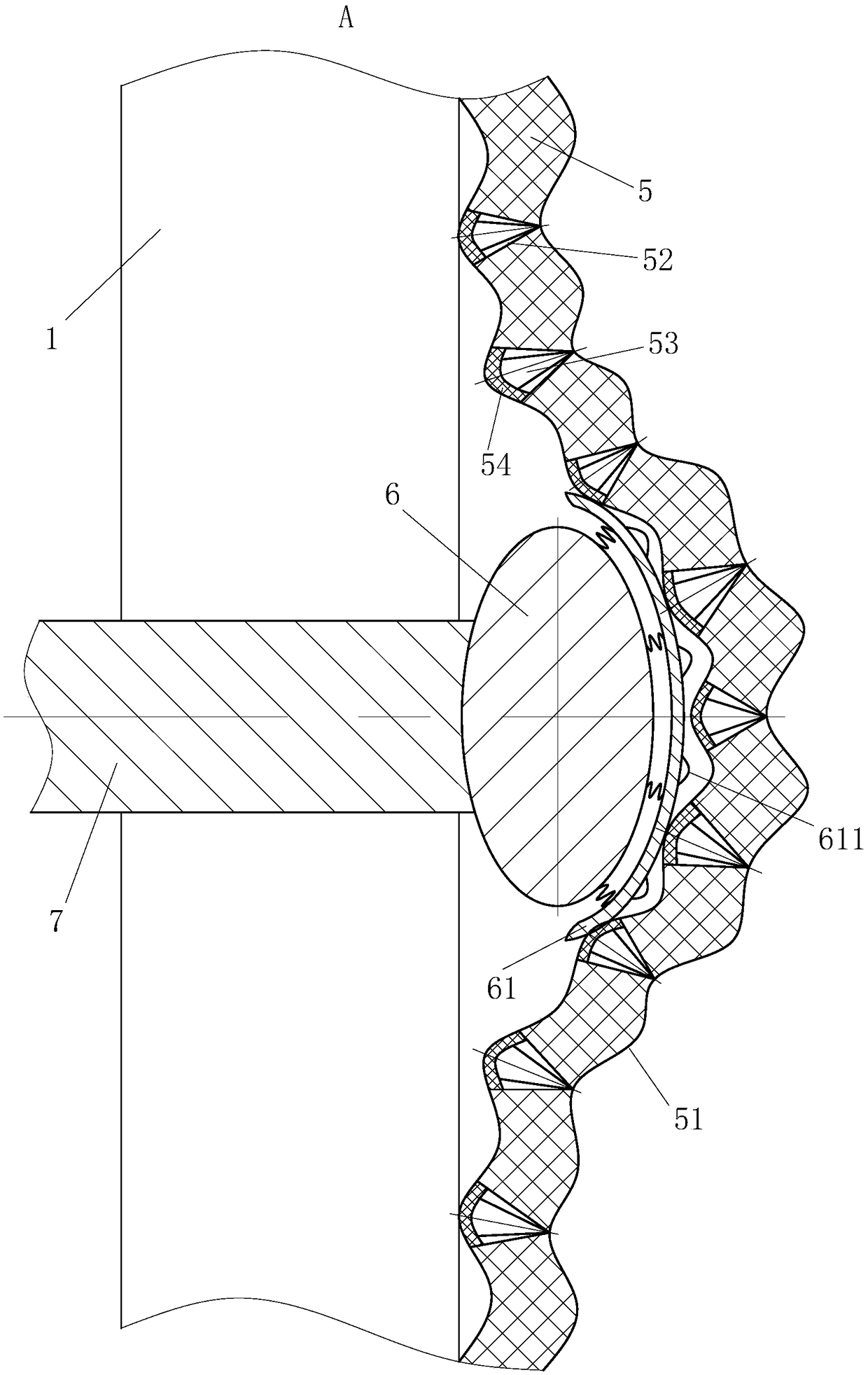

[0029] As an embodiment of the present invention, the surface of the arc-shaped baffle 61 near the inner container 5 is provided with an arc-shaped protrusion 611; during operation, the arc-shaped protrusion 611 on the surface of the arc-shaped baffle 61 increases the The extrusion degree of the curved rubber pad 54 on the surface of the inner container 5 increases further after the cone thorn 53 pierces the inner container 5, and the groove on the wave surface 51 of the inner container 5 undergoes greater deformation, so that the inner surface of the inner container 5 is The industrial salt crystal particles fall; on the other hand, the arc-shaped protrusion 611 on the arc-shaped baffle 61 slides over the arc-shaped rubber pad 54 to make the arc-shaped baffle 61 produce greater vibration, so that the inner surface of the inner container 5 The removal of industrial salt crystal particles is more thorough.

[0030] When working, after a period of wastewater desalination reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com