Permeable crystallization type self-repairing concrete structure and manufacturing method thereof

A technology of concrete structure and osmotic crystallization, which is applied in the field of osmotic crystalline self-repairing concrete structure and its production, which can solve problems such as high cost, shortened service life, and catastrophic accidents, so as to improve waterproof and impermeable properties and reduce high costs , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

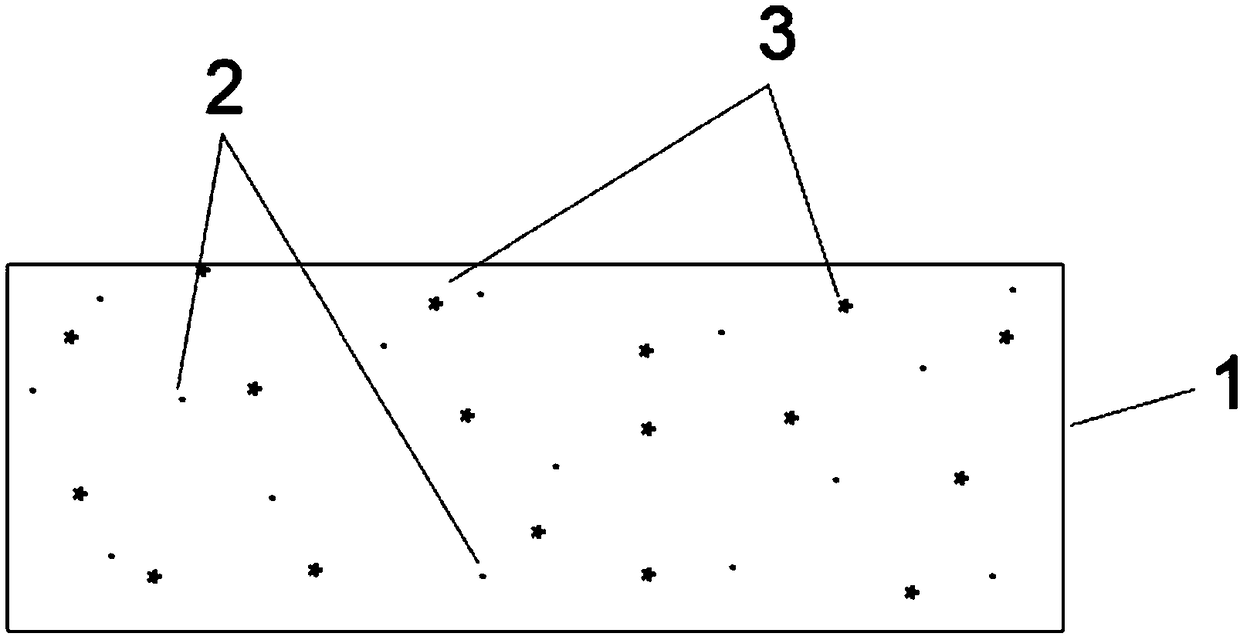

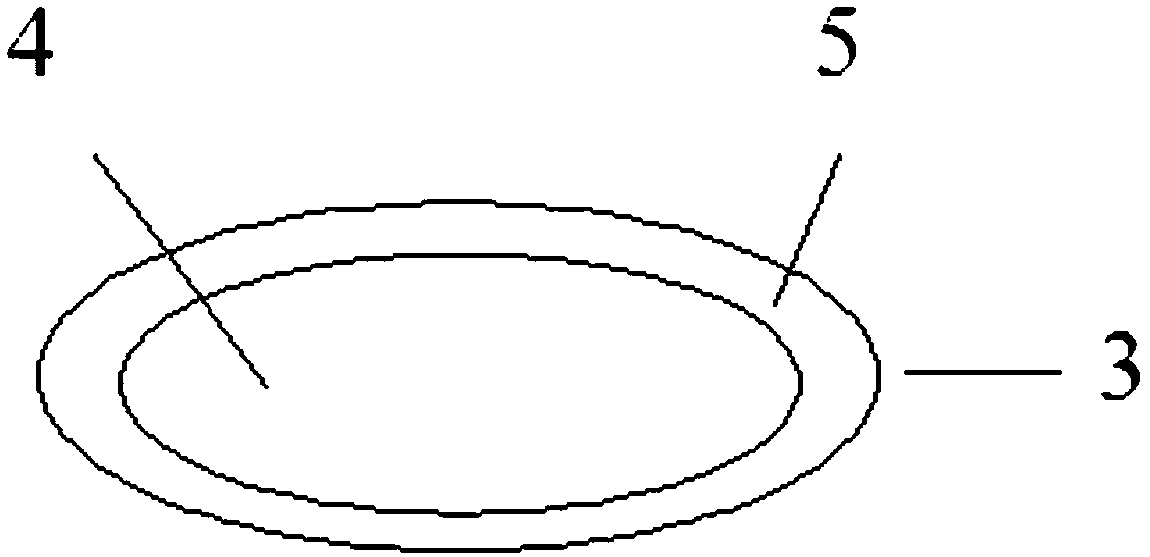

[0028] like Figure 1~2 As shown, a osmotic crystalline self-healing concrete structure includes a concrete member 1, and the osmotic crystalline material particles 2 and sodium silicate repairing agent particles 3 are uniformly arranged in the concrete member 1, and the sodium silicate repairing agent particles 3 has a microcapsule structure, wherein the capsule core material of the sodium silicate restoration agent particle 3 is anhydrous sodium silicate 4, and the capsule wall material is ethyl cellulose 5. The infiltrated crystalline material particles 2 are active silicon infiltrated crystalline masterbatch. The sodium silicate restoration agent particles 3 are flake particles with a diameter of 5-6 mm.

Embodiment 2

[0030] A method for making a self-repairing concrete structure as described, comprising the steps of:

[0031] Step 1: making sodium silicate restorative agent granules 3;

[0032] Step 2: Design the concrete mix ratio, determine the amount of osmotic crystalline material particles 2 and sodium silicate repair agent 3, wherein the osmotic crystalline material granules 2 replace cement with a proportion of 1.85%~2.15%, and the sodium silicate repair The volume ratio of agent particle 3 to cement volume is 4.0%~4.5%;

[0033] Step 3: Pouring the concrete on the concrete member and curing it.

[0034] In this embodiment, the step 1 specifically includes:

[0035] Step 11: Pour ethanol into the container, then pour the ethyl cellulose 5 into the container, mix and stir evenly, and dissolve the ethyl cellulose 5;

[0036] Step 12: Pour the anhydrous sodium silicate 4 into the container again, and stir to mix evenly;

[0037] Step 13: heating the container to accelerate the vola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com