A double anti-counterfeit material, anti-counterfeit label, preparation method and anti-counterfeit detection method

An anti-counterfeit label, double technology, applied in the direction of identification devices, instruments, seals, etc., to achieve the effect of shape memory anti-counterfeiting function, easy recycling, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] Take 9.5 g of dimethyl sebacate and 3.7 g of 1,3 diamino-2-propanol and mix them uniformly at 70°C, add 250 μL of sodium methoxide solution (concentration: 5 mol / L), seal and heat at 70°C for 12 hours. Connect the water pump to evacuate and heat to 100°C for 2 hours until there is no liquid in the reaction system. Replace the water pump with an oil pump to evacuate and heat to 150°C for 1 hour. Finally, the oil pump is vacuumed and heated to 220°C for 1 hour to obtain a double anti-counterfeiting material.

[0036] The glass transition temperature of the double anti-counterfeiting material is 50°C, and the degradation temperature is 280°C; the breaking strength of the material is 70MPa, the elongation at break is 8%, and the toughness after moisture absorption is 45MJ / m 3 .

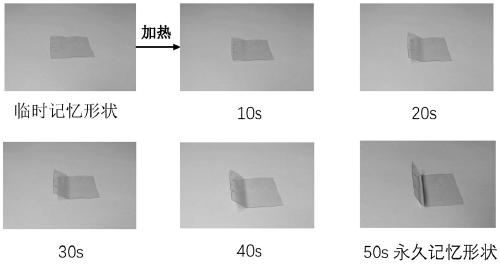

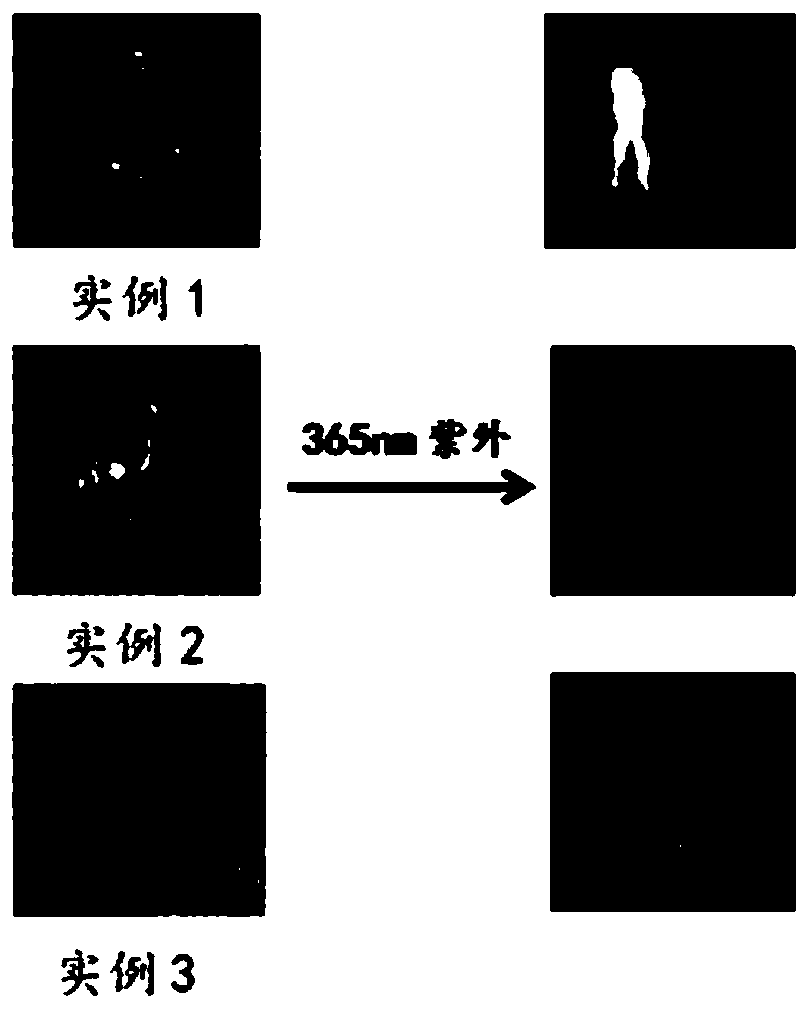

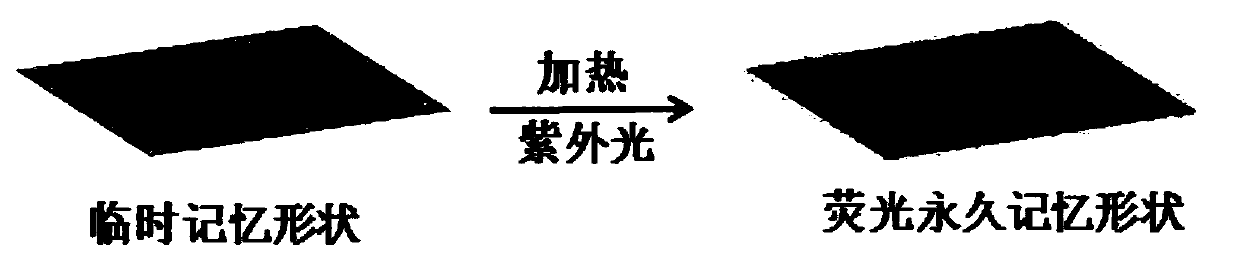

[0037] Using a tablet press, the tablet press mold is designed with a variety of shapes or characters, and a certain distance is set between the shapes or characters (the distance is set according ...

example 2

[0039] Take 13.5 g of dimethyl malonate and 9.3 g of 1,3 diamino-2-propanol and mix them uniformly at 70°C, add 650 μL of sodium methoxide solution (concentration: 5 mol / L), seal and heat at 70°C for 10 hours. Connect the water pump to evacuate and heat to 100°C for 1 hour until there is no liquid in the reaction system. Replace the water pump with an oil pump to evacuate and heat to 150°C for 0.8 hours. Finally, the oil pump vacuumizes and heats to 220°C for 1 hour to prepare a double anti-counterfeiting material .

[0040] The glass transition temperature of the double anti-counterfeiting material is 120°C, and the degradation temperature is 300°C; the breaking strength of the material is 110MPa, the elongation at break is 5%, and the toughness after moisture absorption is 52MJ / m 3 .

[0041]Using a tablet press, the tablet press mold is designed with a variety of shapes or characters, and a certain distance is set between the shapes or characters (the distance is set accor...

example 3

[0043] Take 5.9 g of dimethyl terephthalate and 2.8 g of 1,3 diamino-2-propanol and mix them uniformly at 70°C, add 190 μL of sodium methoxide solution (concentration: 5 mol / L), seal and heat at 70°C for 10 hours. Connect the water pump to evacuate and heat to 100°C for 1.5h until there is no liquid in the reaction system. Replace the water pump with an oil pump to evacuate and heat to 150°C for 0.5h. Finally, the oil pump is evacuated and heated to 220°C for 0.8h to prepare a double Anti-counterfeiting material.

[0044] The glass transition temperature of the double anti-counterfeiting material is 90°C, and the degradation temperature is 290°C; the breaking strength of the material is 100MPa, the elongation at break is 7%, and the toughness after moisture absorption is 43MJ / m 3 .

[0045] Using a tablet press, the tablet press mold is designed with a variety of shapes or characters, and a certain distance is set between the shapes or characters (the distance is set accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com