A kind of cross-linked biological enzyme catalyst and its application

A catalyst and bio-enzyme technology, applied in the direction of biochemical equipment and methods, enzymes, hydrolytic enzymes, etc., can solve the problems of affecting enzyme activity and mass transfer limitations, and achieve the effects of low price, easy availability of raw materials, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

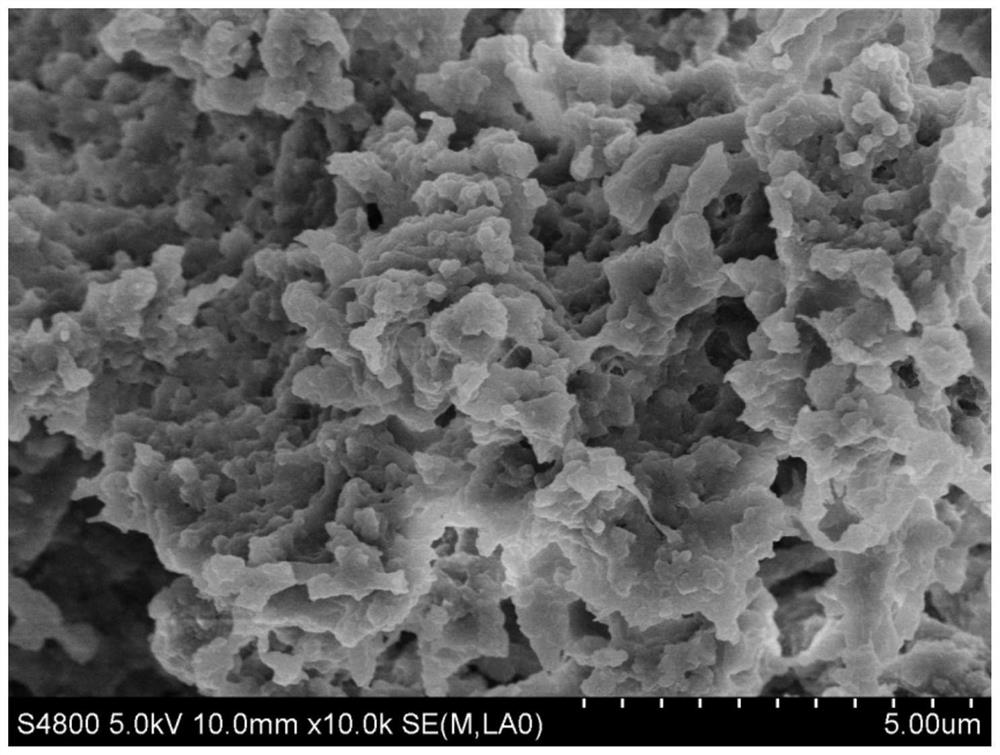

[0029] Dissolve 50 mg of bovine serum albumin in 2 mL of phosphate buffer, add 1 mL of Candida antarctica lipase solution, stir well, add 1.083 g of ammonium sulfate and 30 μL of glutaraldehyde (50 wt %), and stir for 2 Centrifuge after 1 hour, collect the solid body, and wash repeatedly with phosphate buffer saline to obtain cross-linked enzyme aggregates. Then add 3 mL of phosphate buffer to disperse the cross-linked enzyme polymer, stir well, add 50 μL of glutaraldehyde (50 wt %), continue stirring for 30 minutes under ice-water bath conditions, add 1 mL of Candida antarctica lipase solution, and place on ice Stir in a water bath for 1 hour for the second cross-linking, wash after centrifugation, and freeze-dry in a freeze dryer. The sample is marked as Com-CLEAs-1, figure 1 It is the SEM picture of the prepared cross-linked biological enzyme catalyst.

Embodiment 2

[0031] Dissolve 100 mg of bovine serum albumin in 2 mL of phosphate buffer, add 1 mL of Candida antarctica lipase solution, stir well, add 1.083 g of ammonium sulfate and 30 μL of glutaraldehyde (50 wt %), and stir for 2 Centrifuge after 1 hour, collect the solid body, and wash repeatedly with phosphate buffer saline to obtain cross-linked enzyme aggregates. Then add 3 mL of phosphate buffer to disperse the cross-linked enzyme polymer, stir well, add 50 μL of glutaraldehyde (50 wt %), continue stirring for 30 minutes under ice-water bath conditions, add 1 mL of Candida antarctica lipase solution, and place on ice Stir in a water bath for 1 hour to carry out the second cross-linking, wash after centrifugation, and freeze-dry in a freeze dryer. The sample is marked as Com-CLEAs-2.

Embodiment 3

[0033] Dissolve 150 mg of bovine serum albumin in 2 mL of phosphate buffer, add 1 mL of Candida antarctica lipase solution, stir well, add 1.083 g of ammonium sulfate and 30 μL of glutaraldehyde (50 wt %), and stir for 2 Centrifuge after 1 hour, collect the solid body, and wash repeatedly with phosphate buffer saline to obtain cross-linked enzyme aggregates. Then add 3 mL of phosphate buffer to disperse the cross-linked enzyme polymer, stir well, add 50 μL of glutaraldehyde (50 wt %), continue stirring for 30 minutes under ice-water bath conditions, add 1 mL of Candida antarctica lipase solution, and place on ice Stir in a water bath for 1 hour to carry out the second cross-linking, wash after centrifugation, and freeze-dry in a freeze dryer. The sample is marked as Com-CLEAs-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com