Difunctional microstructure palladium-based membrane reactor and preparation method thereof

A membrane reactor and microstructure technology, applied in chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, etc., can solve the problem of hydrogen permeation of micron-scale ultra-thin palladium-based membranes. Unsatisfactory rate, restricting hydrogen production efficiency of palladium-based membrane reactor, reducing hydrogen permeation rate of palladium-based membrane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

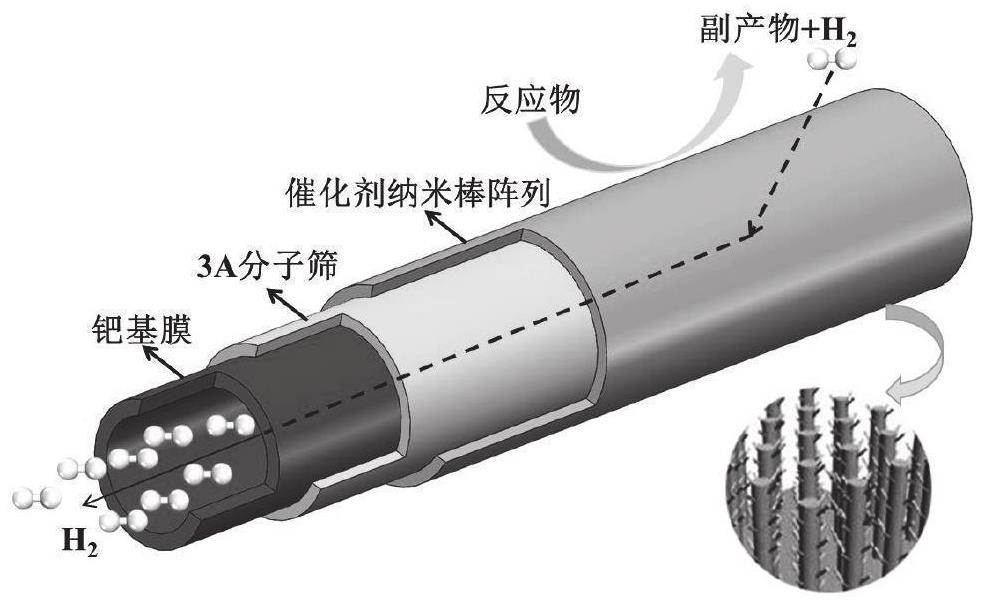

[0019] In a second aspect, the present invention provides a method for preparing a bifunctional microstructure palladium-based membrane reactor, comprising the steps of:

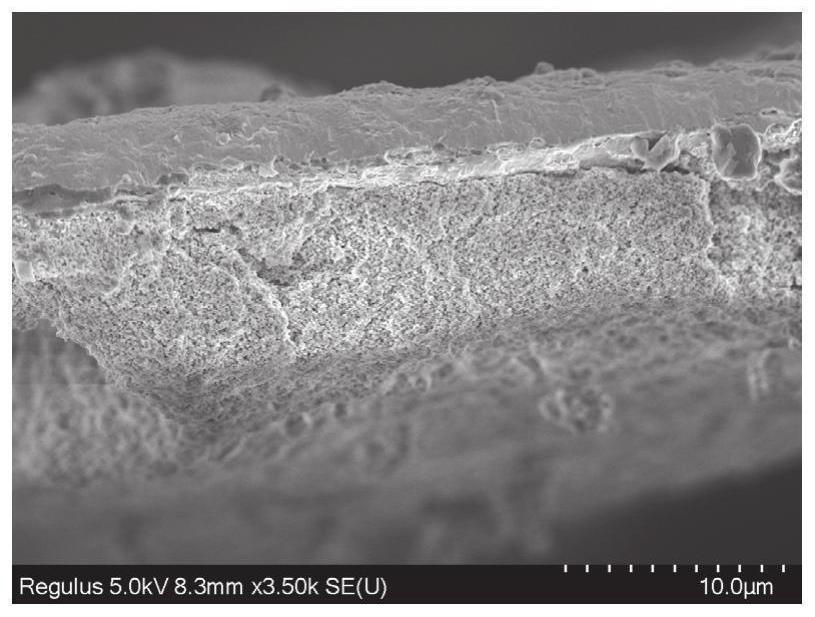

[0020] The surface of the palladium-based composite film was roughened (etched or embedded with raised particles) or functionalized pretreatment by acid treatment, in-situ anchoring of acid palladium nanocrystals or in-situ growth of silane binder, and then hydrothermal 4A molecular sieve was prepared on the surface of palladium-based membrane by synthetic method, and then 3A molecular sieve membrane was prepared by ion exchange method to obtain 3A molecular sieve / palladium-based membrane;

[0021] Preparation of TiO on the surface of 3A molecular sieve / palladium based membrane by hydrothermal synthesis 2 The nanorod array is used as a template to coat the hydrogen production catalyst on its surface to obtain a catalyst nanorod array / 3A molecular sieve / palladium-based membrane, that is, a dual-functional mic...

Embodiment 1

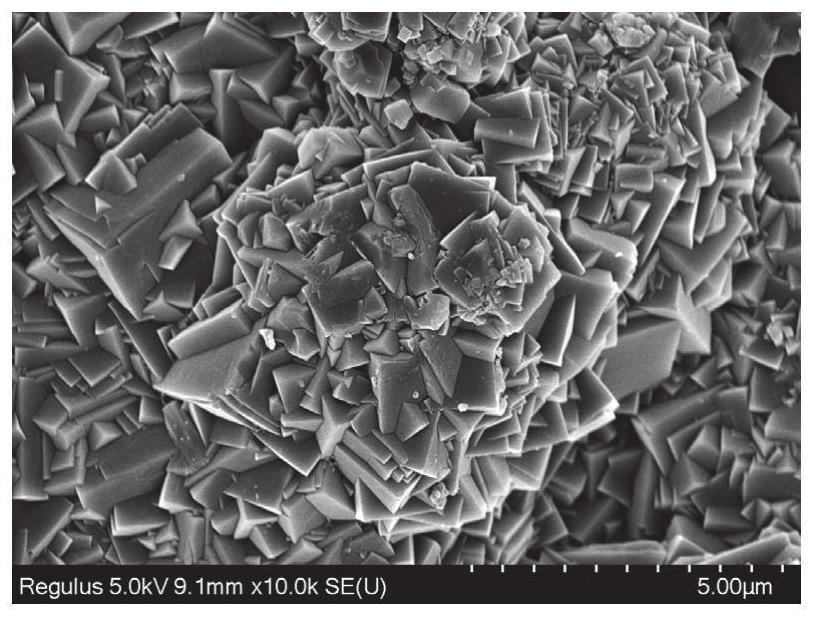

[0055] 1) Soak the palladium membrane in nitric acid solution with pH=2 for 0.5h, then rinse the acid-treated palladium membrane with deionized water, soak for 5h, and dry at 120°C for 4h. Put 11.11g NaOH into 50ml water and stir evenly, then add 0.91g NaAlO 2 Slowly add to NaOH aqueous solution, stir for 2h until clear; put 11.11g NaOH into 50ml water and stir evenly, then slowly add 7.9ml of silica sol into NaOH aqueous solution, stir for 2h until clear; slowly add silicon solution to Aluminum solution, stirred for 2h. The acid-treated palladium membrane tube blocked at both ends is put into a high-pressure stainless steel reactor, the above-mentioned prepared silica-alumina sol is poured into the still and the palladium membrane tube is completely submerged (guaranteeing that the height of the sol is lower than that of the high-pressure stainless steel reactor 2 / 3 locations), put into a homogeneous reactor, rotate at 10r / min, temperature 90°C, react for 3h, take out the r...

Embodiment 2

[0059] Configure acidic palladium nanocrystal solution, in which PdCl 2 , the concentration of reducing agent ascorbic acid, dispersant sodium dodecyl sulfate (SDS) is respectively 9.6g / L, 26.6g / L, 62.5g / L, dilute hydrochloric acid is adjusted to solution pH and is 3, puts palladium film into above-mentioned The palladium nanocrystal suspension was reacted at 60°C for 2h, and then the pretreated palladium membrane was rinsed with deionized water, soaked for 5h, and dried at 120°C for 4h. Put 11.11g NaOH into 50ml water and stir evenly, then add 0.91g NaAlO 2 Slowly add to NaOH aqueous solution, stir for 2h until clear; put 11.11g NaOH into 50ml water and stir evenly, then slowly add 7.9ml of silica sol into NaOH aqueous solution, stir for 2h until clear; slowly add silicon solution to Aluminum solution, stirred for 2h. The acid-treated palladium membrane tube blocked at both ends is put into a high-pressure stainless steel reactor, the above-mentioned prepared silica-alumina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com