Impregnation device of decorative paper samples

A technology of dipping device and decorative paper, which is applied in the direction of papermaking, textile and papermaking, pulp raw material addition process, etc., can solve the problems such as poor scraping effect, and achieve the effect of saving and controlling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

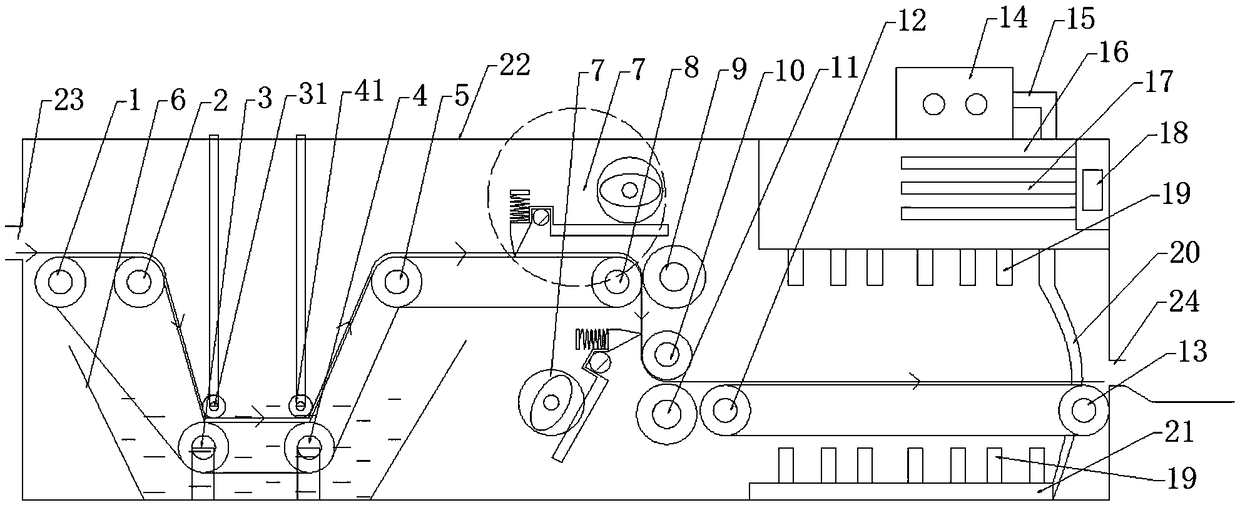

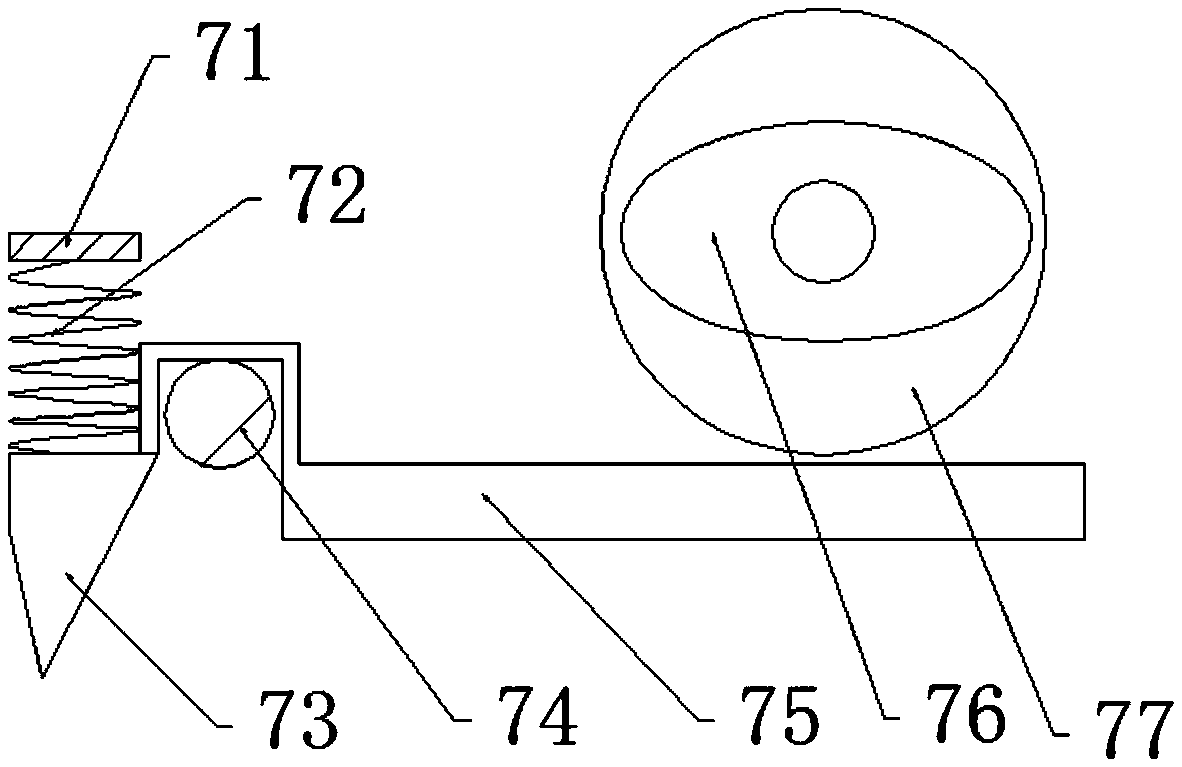

[0031] A device for impregnating decorative paper samples, comprising an outer casing, a fifth traction roller is arranged in the outer casing, a sixth traction roller is arranged on the horizontal side of the fifth traction roller, and the sixth traction roller and the fifth traction roller pass through a conveyor belt One connection, a squeegee mechanism is provided directly above the fifth traction roller and the sixth traction roller, the squeegee mechanism includes a curved tube, and the curved tube body is contacted with a support column fixed on the outer shell. The tube can rotate around the support column. One end of the curved tube is connected with a scraper. The blade surface of the scraper is in contact with the decorative paper sample on the conveyor belt. The other end of the curved tube is in contact with a bump, and the center of the bump is hinged on the outer shell. . Place the dipped decorative paper sample on the conveyor belt 1. When the decorative paper ...

Embodiment 2

[0033] On the basis of Embodiment 1, the blade back of the scraper is also connected with a fixed block through a spring, and the fixed block is fixed on the outer shell; The central connection of the blocks. By setting the spring and the fixed block, the thickness of the squeegee can be adjusted in a wider range, and the final effect of the color difference contrast can be improved; in addition, the longitudinal section of the bump is set as an ellipse, so that when the bump rotates clockwise and counterclockwise Both can achieve good results. The distance between the scraper and the decorative paper sample is adjusted by setting the scraper adjustment block, which saves the control cost and facilitates timely and accurate control of the thickness of the scraper.

Embodiment 3

[0035] On the basis of the above embodiment, a guide roller 1 is provided on one side of the sixth traction roller, and the rotation direction of the guide roller 1 is opposite to that of the sixth traction roller; the seventh traction roller is arranged directly below the guide roller 1, Between the seventh traction roller and the sixth traction roller, a squeegee mechanism is provided on the side of the sixth traction roller; a guide roller 2 is provided below the seventh traction roller, and the distance between the guide roller 2 and the seventh traction roller is related to the decoration The thickness of the paper sample is suitable, the direction of rotation of the second guide roller is opposite to that of the seventh traction roller; the eighth traction roller and the ninth traction roller are arranged on the side of the second guide roller in turn, and the outer shell is close to the ninth traction roller one There is a paper outlet on the side, the eighth traction ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com