Steel tube concrete column bent frame-reinforced concrete core tube structural system

A technology of concrete-filled steel tubular columns and reinforced concrete, which is applied in special structures, building components, building structures, etc., can solve the problems of increasing construction costs and construction workload, limiting the distance between outer frame columns, restricting structural forms, etc. Effects of Seismic Investment, Reduced Section Size, and Relaxation of Interstory Displacement Angle Limits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

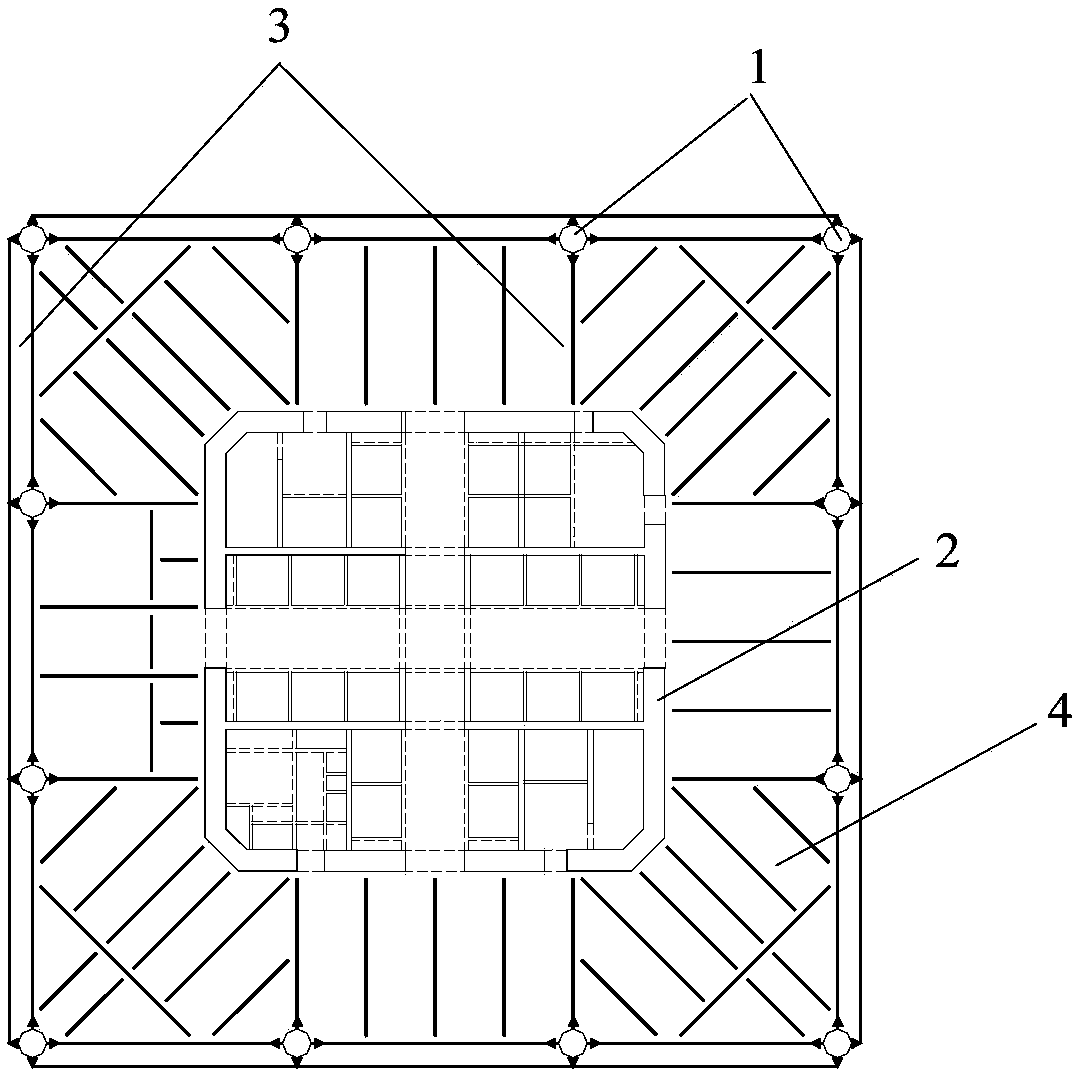

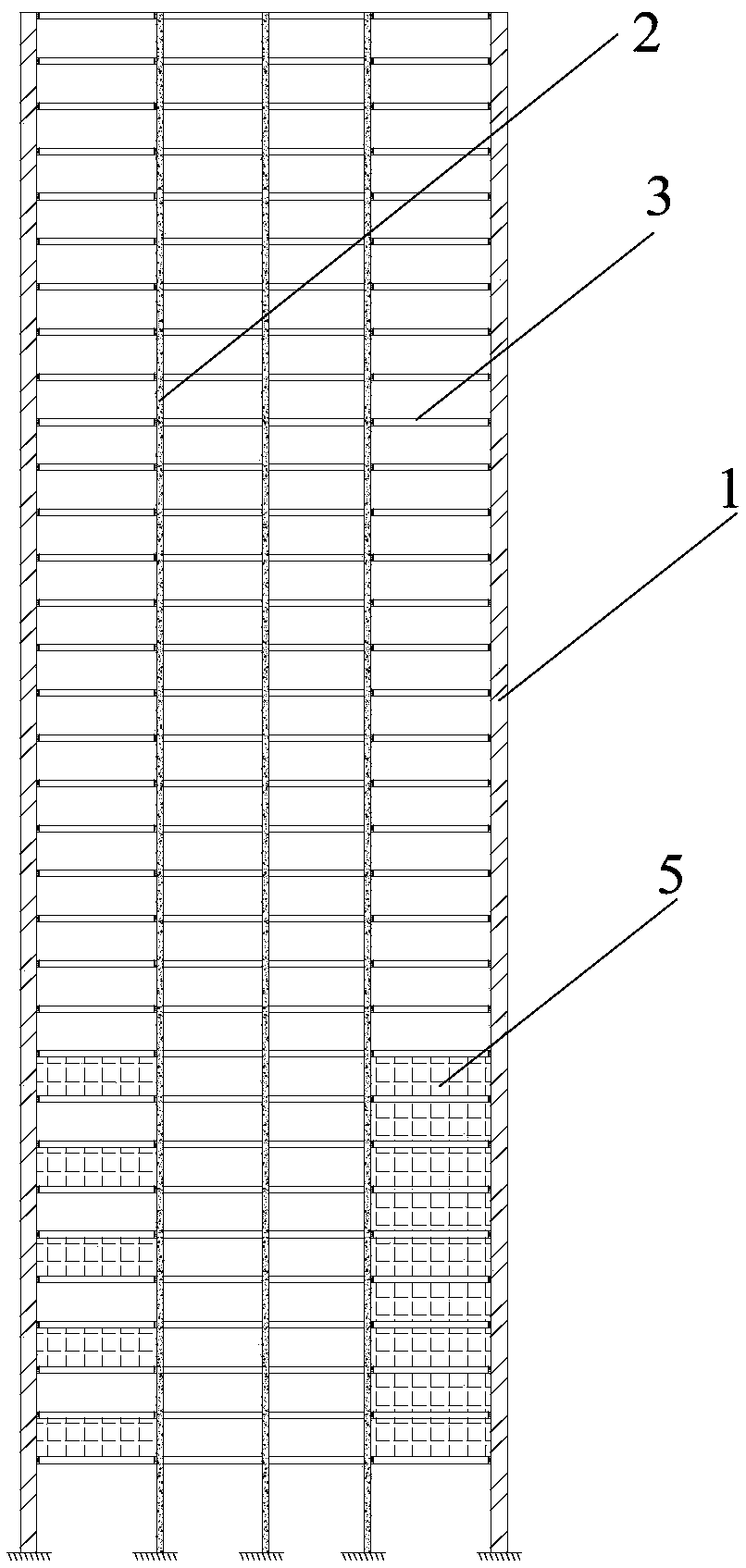

[0031] A steel tube concrete column bent frame-reinforced concrete core tube structure, 300 meters high, including: several steel bent beams, several steel tube concrete columns, reinforced concrete core tube, several layers of cast-in-place concrete floors and precast concrete poured on site wall panels. Such as figure 1 As shown, the concrete-filled steel tube columns are arranged around the concrete core tube to form a square plane, in which four concrete-filled steel tube columns are arranged at equal intervals on each side.

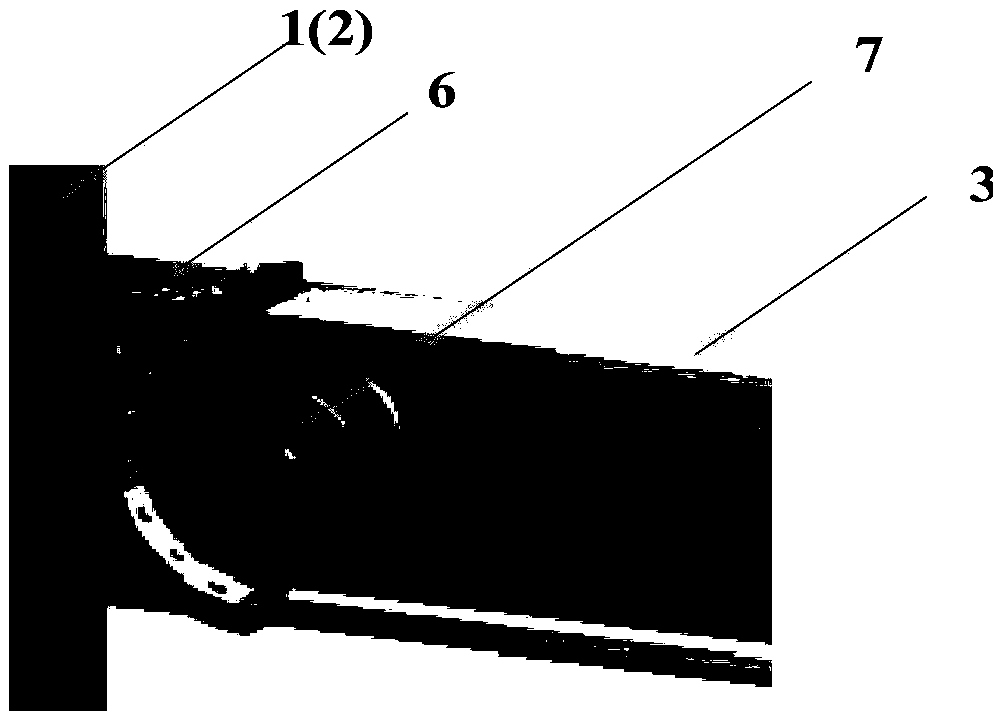

[0032] Such as image 3 As shown, in this embodiment, the hinge joint is a single bolt hinge, and the steel bent beam includes two cantilever sections at both ends and a middle section, and the cantilever section is pre-anchored at the joint connection position of the steel tube concrete column and the shear wall of the reinforced concrete core tube On the construction site, the middle section and the cantilever section are hinged by a single bolt....

Embodiment 2

[0034] Such as Figure 4As shown, in this embodiment, the hinge joint is a multi-bolt equivalent hinge, and the cantilever hanger is anchored at the connection position of the steel tube concrete column joint or the shear wall of the reinforced concrete core tube. When installing the steel bent beam, both ends of the steel bent beam are equivalently hinged with the cantilever hanger through multi-bolts. In this embodiment, the concrete floor slab is formed by pouring on-site prefabricated concrete laminated floor slabs. Prefabricated concrete laminated floor slabs are used to reduce on-site workload and improve construction efficiency.

[0035] Parts not mentioned in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com