Composite wall panel for prefabricated steel structure building and its manufacturing and installation method

A composite wallboard and steel structure technology, which is applied to buildings, building components, building structures, etc., can solve the problems affecting the popularization and application of prefabricated steel structure buildings, affecting the thermal insulation and sound insulation effects of wallboards, and cracking of cement mortar plastering layers, etc. problems, to achieve the effect of easy control of installation accuracy, solving freezing and thawing problems, and reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

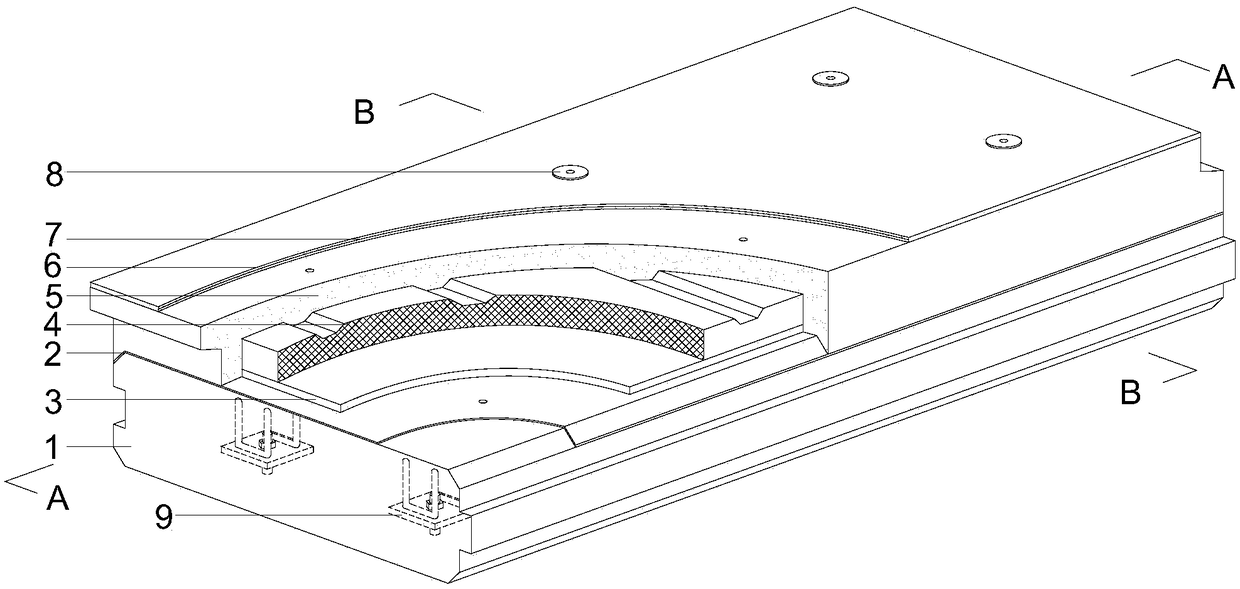

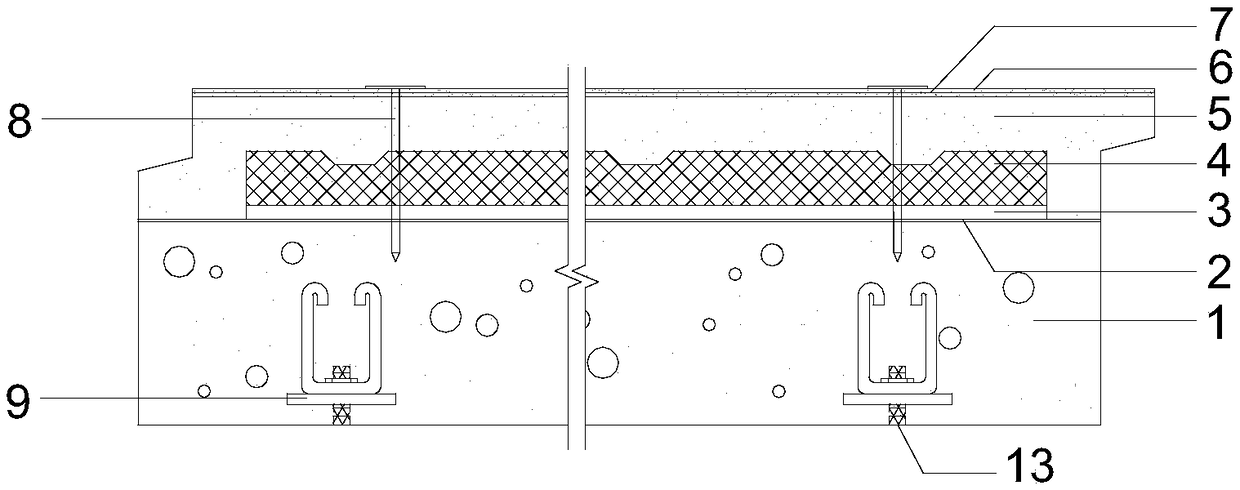

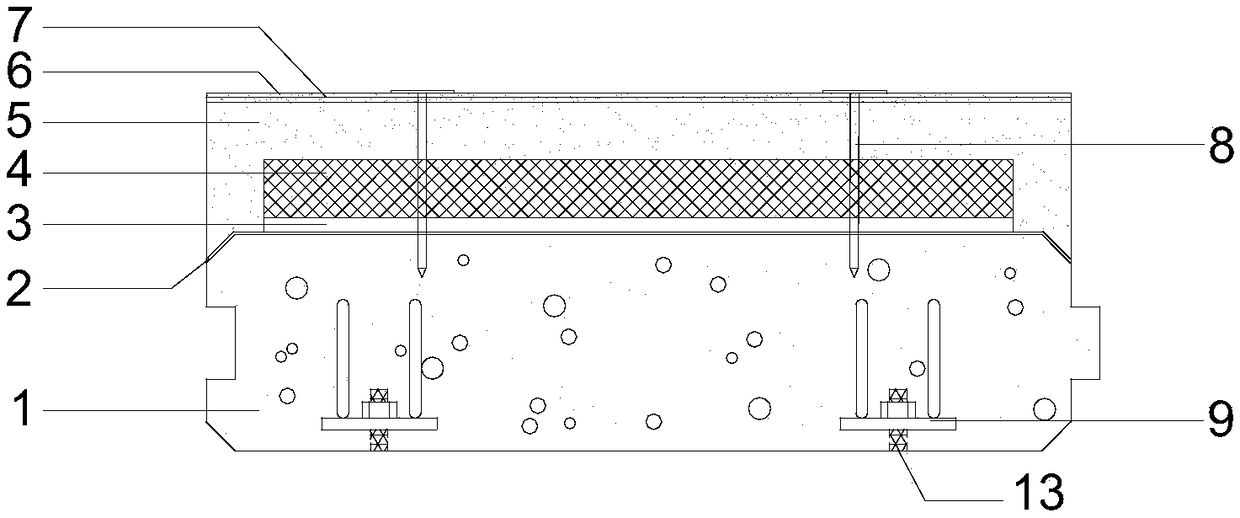

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the composite wall panels used for prefabricated steel structure buildings include aerated concrete slab base 1, interface treatment layer 2, adhesive layer 3, insulation layer 4, protective layer 5, and anti-crack surface layer from bottom to top. 6; Among them, the base layer 1 of the aerated concrete slab and the insulation layer 4 are bonded together through the interface treatment layer 2 and the adhesive layer 3, and the upper surface of the insulation layer 4 is poured with a thermal insulation slurry protective layer 5, and the protective layer 5 seals the thermal insulation layer. 4 Completely wrapped; the upper side of the protective layer is painted or sprayed with an anti-crack surface layer 6, and the plastic anchor bolt 8 mechanically anchors the protective layer 5, the insulation layer 4 and the air concrete plate base 1 together.

[0030] The base 1 of the aerated concrete slab is made of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com