Mushroom-shaped blade root, steam turbine blade and steam turbine

A steam turbine blade, steam turbine technology, applied in the direction of machine/engine, blade supporting element, mechanical equipment, etc., can solve the problems of pressure difference on both sides and the reduction of blade stability, so as to reduce the pressure difference, improve the axial thrust, ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

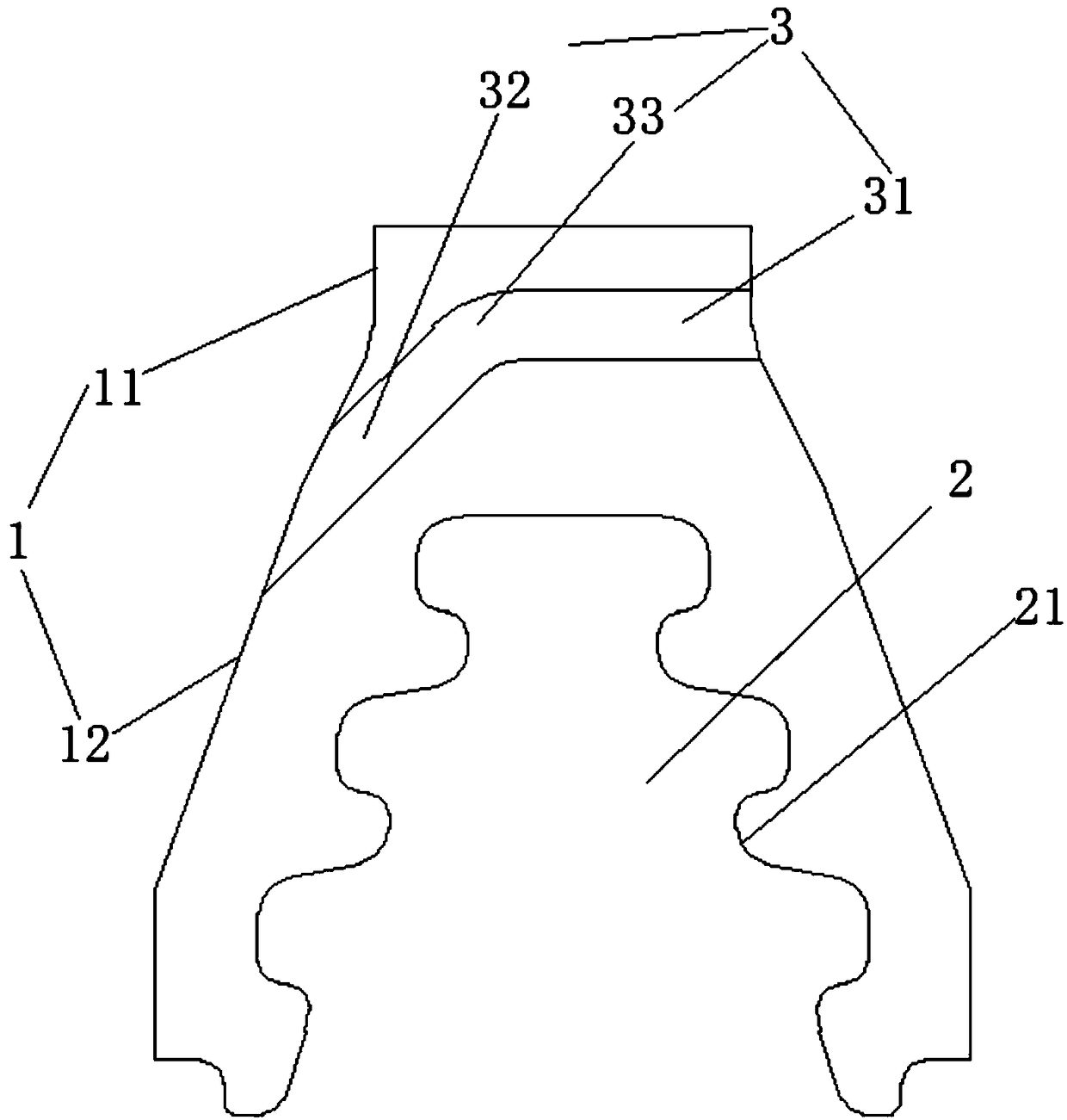

[0030] see figure 1 , this embodiment provides a fungus-type leaf root, including a root body 1, a root wheel groove 2 is arranged on the root body 1, the root wheel groove 2 opens downward, and the front and the front of the root wheel groove 2 The rear two ends are open, that is, the root wheel groove 2 is a groove that runs through the front and rear ends and is open on the ground. The left and right groove surfaces of the root wheel groove 2 are respectively provided with wheel flange protrusions 21 . The front and rear sides of the root body 1 are respectively provided with balance grooves 3, and the balance grooves 3 are arranged on the root body 1 above the root wheel groove 2 and / or the balance grooves 3 are arranged on On the root body 1 corresponding to the upper part of the root wheel groove 2 .

[0031] It should be noted that the above-mentioned front, back, left, and right are all descriptions for illustrating relative positional relationships, and the front and...

Embodiment 2

[0053] This embodiment provides a steam turbine blade, and the bottom of the steam turbine blade is integrally connected with the mushroom-shaped blade root described in the first embodiment above. That is to say, the steam turbine blade in this embodiment is provided with the fungus-shaped blade root in the first embodiment, and the entire steam turbine blade is of an integral structure.

[0054] Specifically, the steam turbine blade includes a fungus-shaped blade root and a leaf body arranged on the upper part of the blade root.

[0055] The fungus-type leaf root comprises a root body 1, and the root body 1 is provided with a root wheel groove 2, and the root wheel groove 2 opens downward and the front and rear ends of the root wheel groove 2 are opened, and the root wheel groove 2 is opened. The left and right groove surfaces of the root wheel groove 2 are respectively provided with flange protrusions 21 . The front and rear sides of the root body 1 are respectively provid...

Embodiment 3

[0059] This embodiment provides a steam turbine, the rotor of which is connected with the steam turbine blade described in the second embodiment.

[0060] Specifically, the steam turbine blade includes a fungal root and a leaf body arranged on the upper part of the root. The fungus-type leaf root comprises a root body 1, and the root body 1 is provided with a root wheel groove 2, and the root wheel groove 2 opens downward and the front and rear ends of the root wheel groove 2 are opened, and the root wheel groove 2 is opened. The left and right groove surfaces of the root wheel groove 2 are respectively provided with flange protrusions 21 . The front and rear sides of the root body 1 are respectively provided with balance grooves 3, and the balance grooves 3 are arranged on the root body 1 above the root wheel groove 2 and / or the balance grooves 3 are arranged on On the root body 1 corresponding to the upper part of the root wheel groove 2 . The shape of the leaf body and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com