Air sealing structure and method for thrust and guiding bearings of water-turbine generator set

A generator set and hermetic sealing technology, applied in hydropower, engine components, machines/engines, etc., can solve problems such as poor sealing effect, seal wear, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

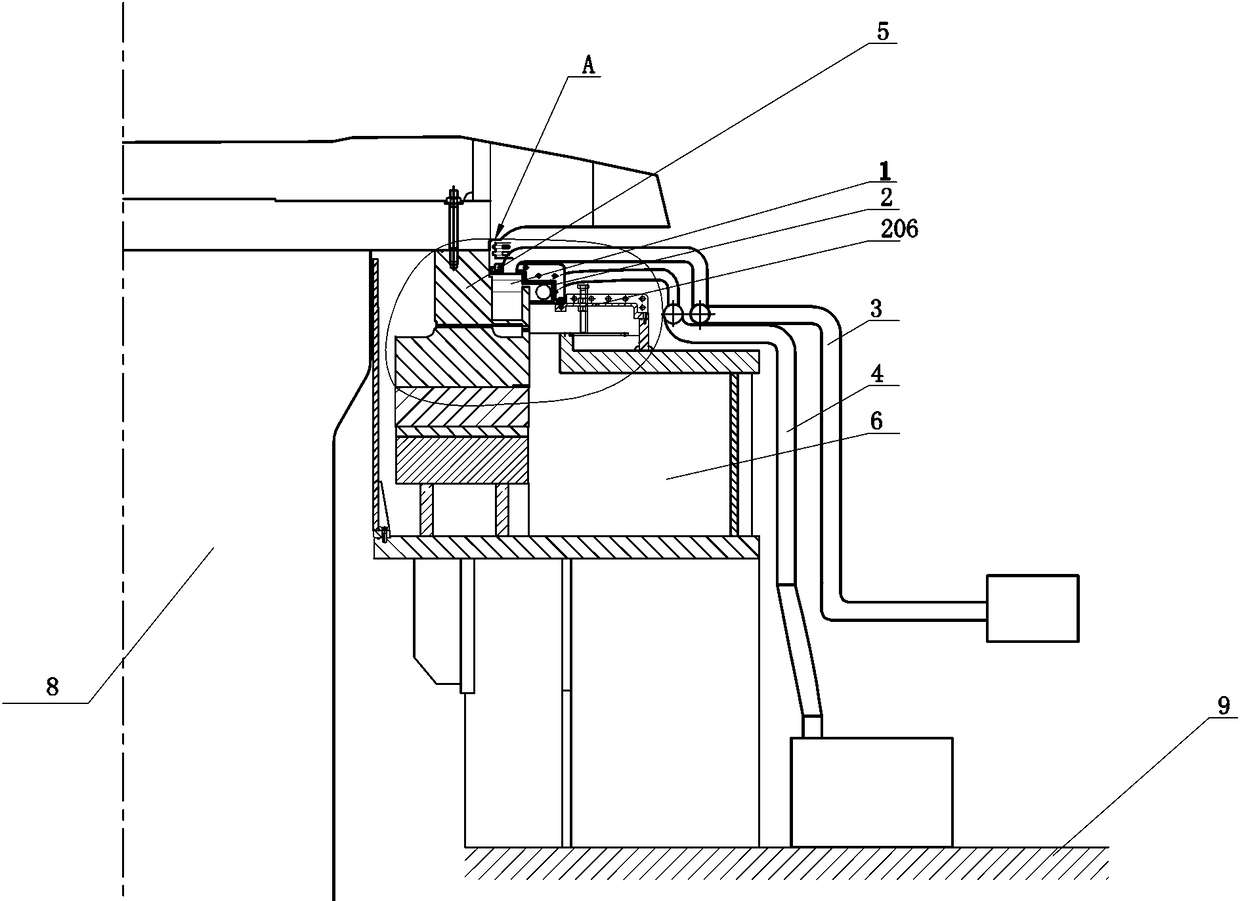

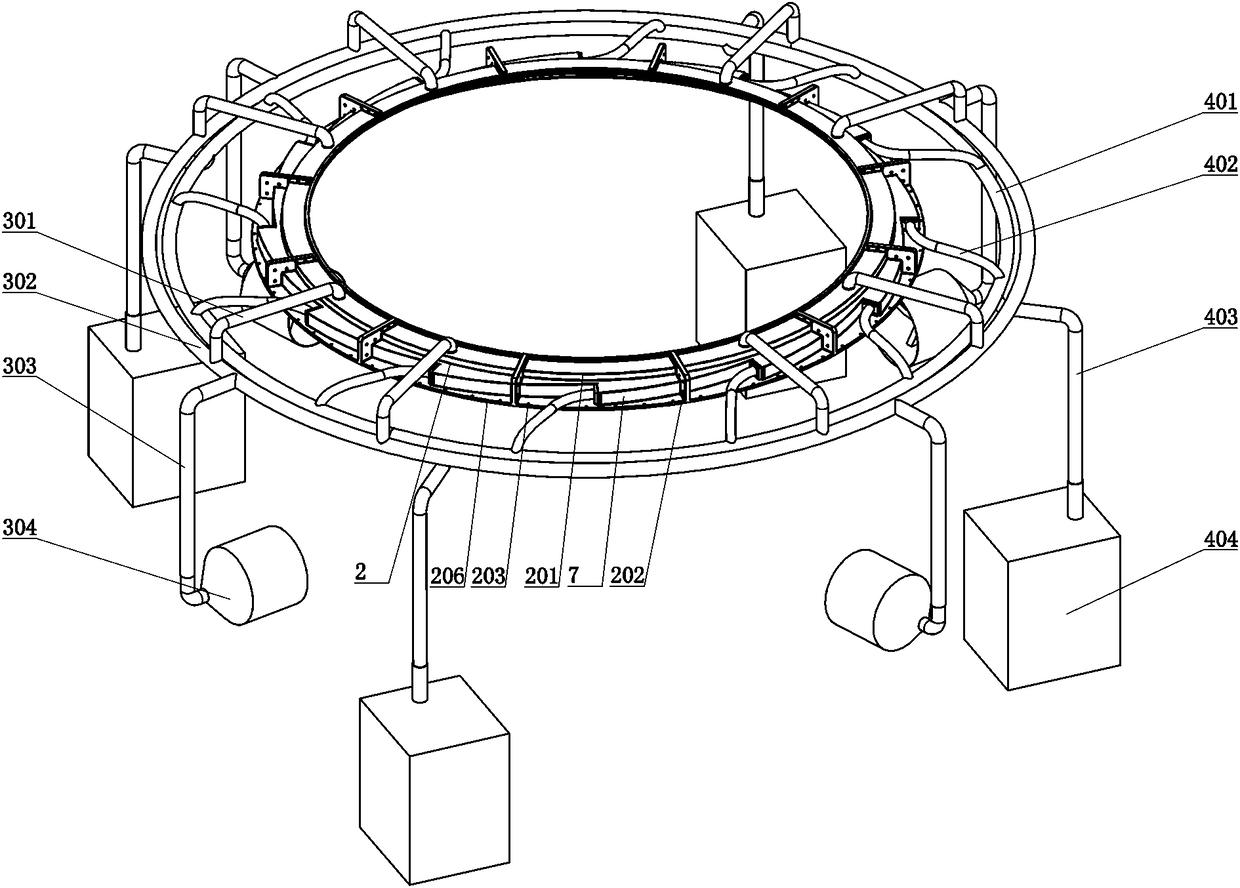

[0036] like Figure 1-6 As shown in the figure, a hydro-generator set derives an air-tight structure of the bearing, which mainly includes a rotating fan blade 1, an inner oil tank cover 2, an air supply system 3, and an oil mist absorption system 4. specifically:

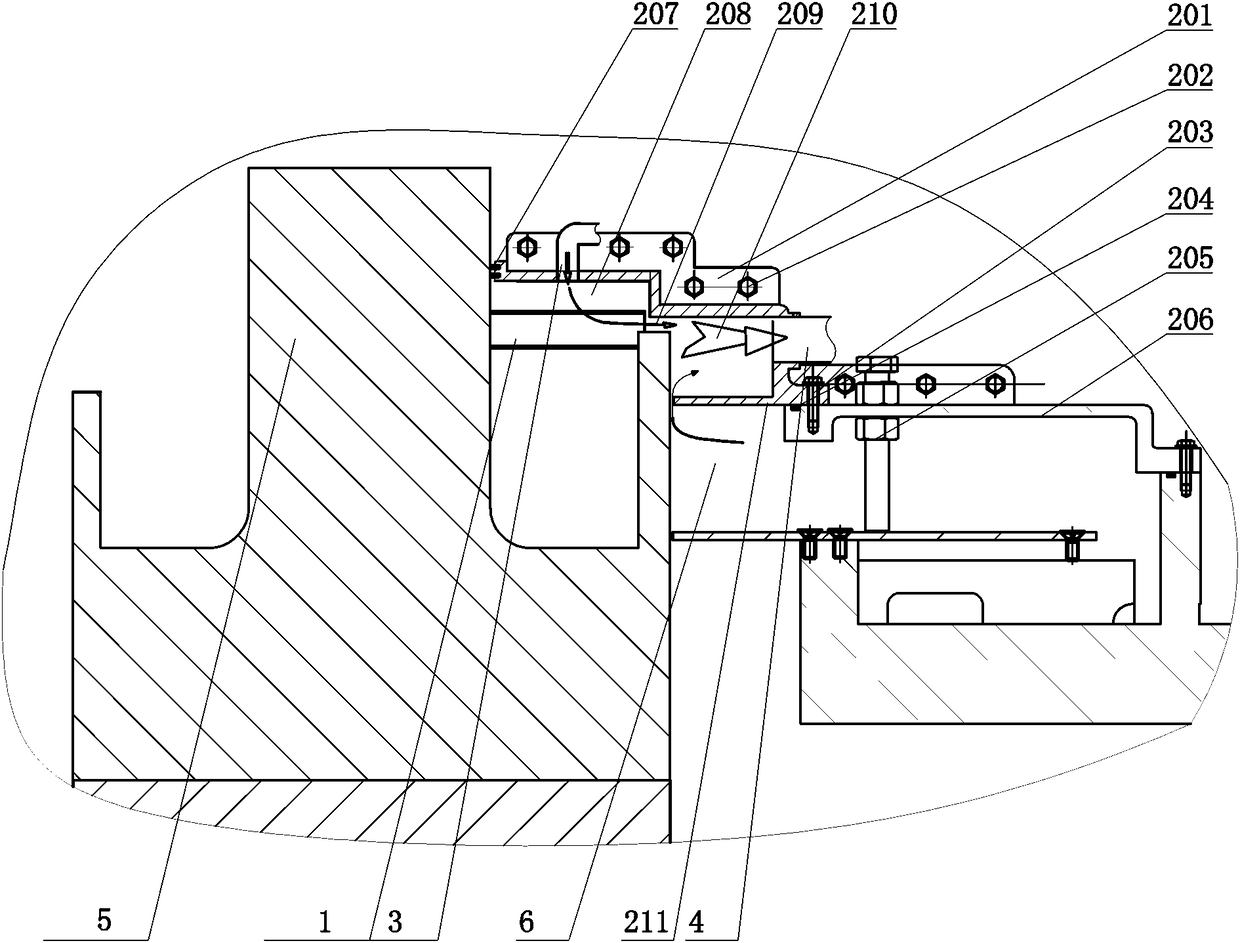

[0037] The rotating fan blade 1 is a backward curved blade shape, and the bottom is provided with a deflector plate 10, a total of 36 pieces (calculated according to the simulation). 36 pieces of rotating fan blades 1 are evenly distributed and welded in the groove of the thrust head 5. During the rotation of the large axis of the random group, a radial high-speed airflow is formed in the radial flow channel 209 .

[0038] The inner oil tank cover 2 is composed of 12 split structures 201 , each split structure 201 is sealed and spliced into a complete circle using connecting bolts 202 . The inner oil tank cover 2 is fixed on the original outer oil tank cover 206 by fastening bolts 203, and a first gasket 204 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com