A cantilever variable-gap plane cascade experimental device

An experimental device, a technology of variable clearance, which is applied to the components of the pumping device for elastic fluids, the components of the variable volume pump, and the liquid variable volume machinery, etc. Blade structure design and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

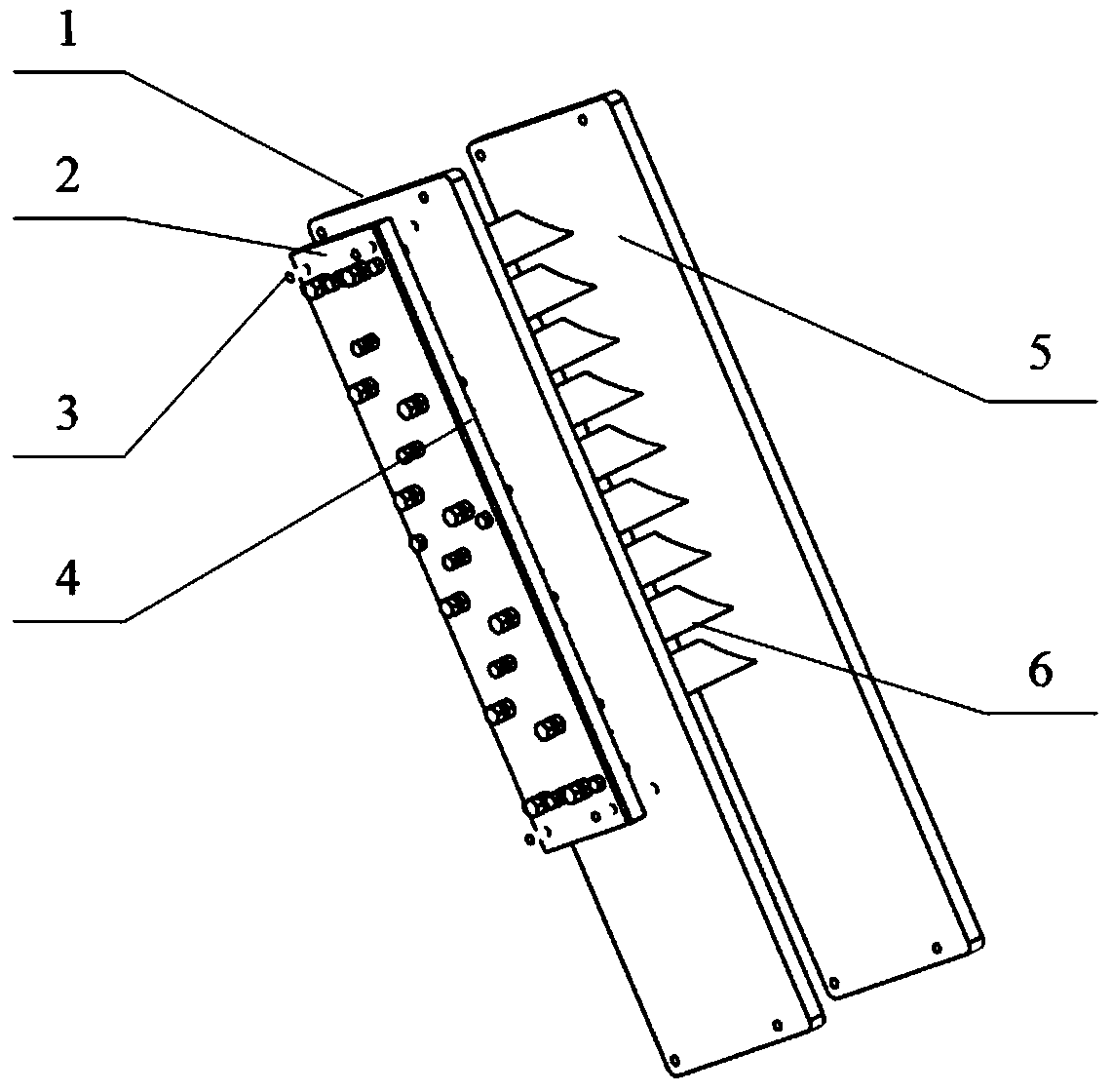

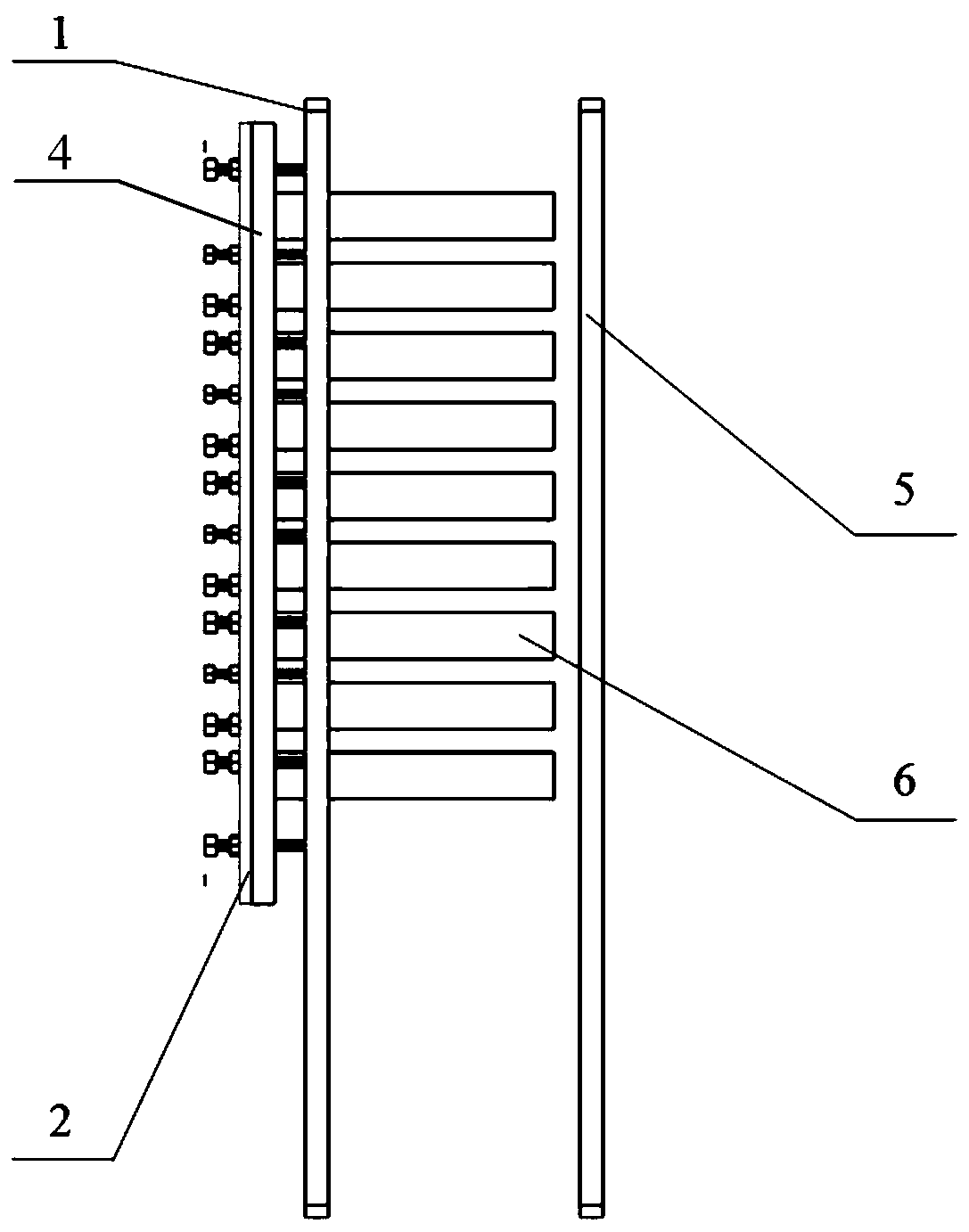

[0026] Such as Figure 1 to Figure 3 As shown, a cantilever variable-gap planar cascade test device includes left grid plate 1, blade fixed end plate 2, positioning pin 3, blade fixing plate 4, right grid plate 5, blade 6, positioning screw 7, and fixing bolt 8 And jacking bolt 9, wherein:

[0027] The left grid plate 1 and the right grid plate 5 are arranged oppositely, and the left grid plate 1 and the right grid plate 5 are respectively connected to the test bench through threads, a blade 6 is arranged between the left grid plate 1 and the right grid plate 5, and a The first airfoil through-hole 10 that matches the profile of the blade 6, the blade 6 is installed on the left grid 1 through the first airfoil through-hole 10 and keeps a gap with the right grid 5, so as to realize the fixation of the cantilever blade 6 on one side; The side of the left grid plate 1 away from the right grid plate 5 is provided with threaded blind holes;

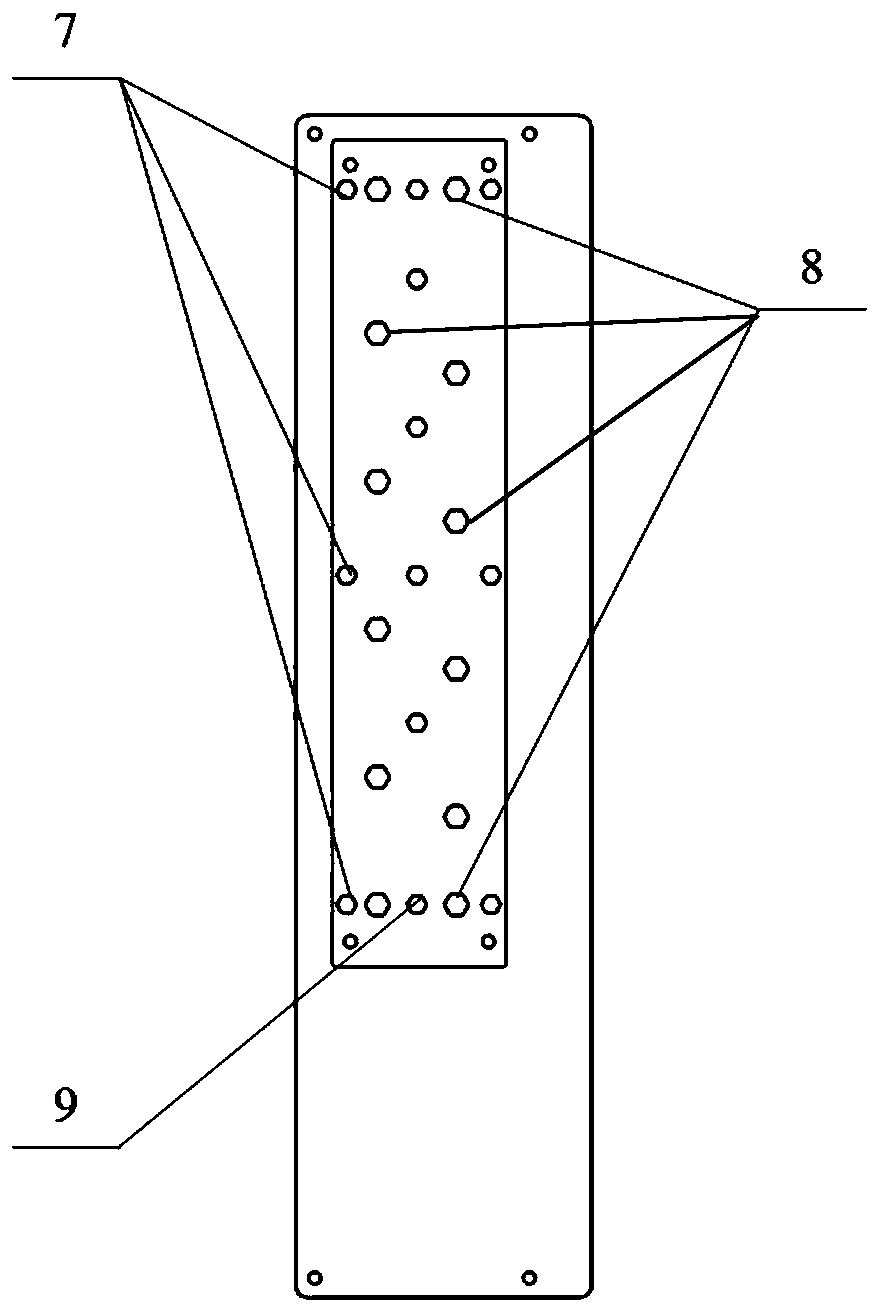

[0028] Such as Figure 4 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com