A device for measuring liquid phase distribution characteristics in a self-priming Venturi scrubber

A technology of liquid phase distribution and water washer, which is applied in the direction of measuring device, liquid/fluid solid measurement, measurement flow/mass flow, etc. It can solve the problem of changing the characteristics of liquid absorption, unable to expand the application of self-priming Venturi water washer, lack of liquid Membrane flow separation and measurement to achieve effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings.

[0029] The invention particularly relates to an experimental device for measuring liquid phase distribution characteristics in a Venturi water scrubber of a containment filter discharge system. In order to solve the deficiencies of the prior art, the present invention expects to provide a continuously adjustable method to separate liquid films of different thicknesses under the condition of keeping the liquid level constant, thereby enabling the self-priming Venturi water washer to be guided It is a device for accurate measurement of injection volume and liquid film flow rate; at the same time, it can measure the droplet size without affecting the droplet speed and droplet shape.

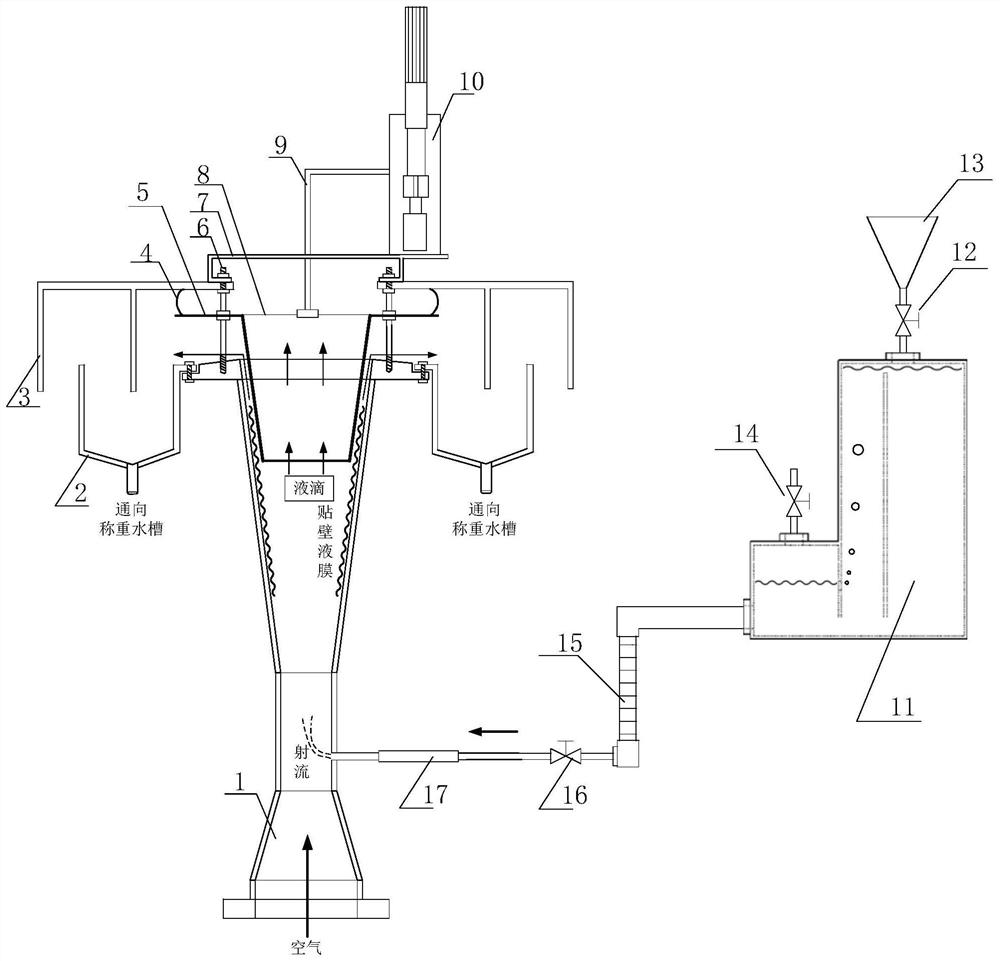

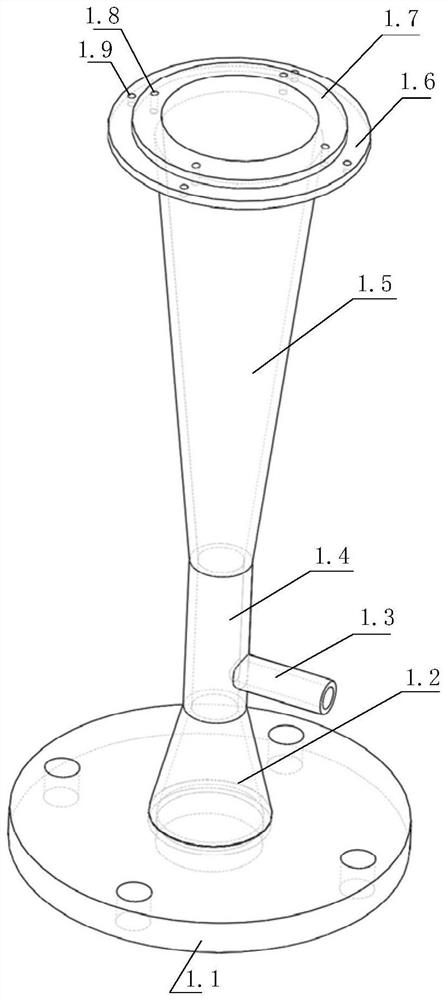

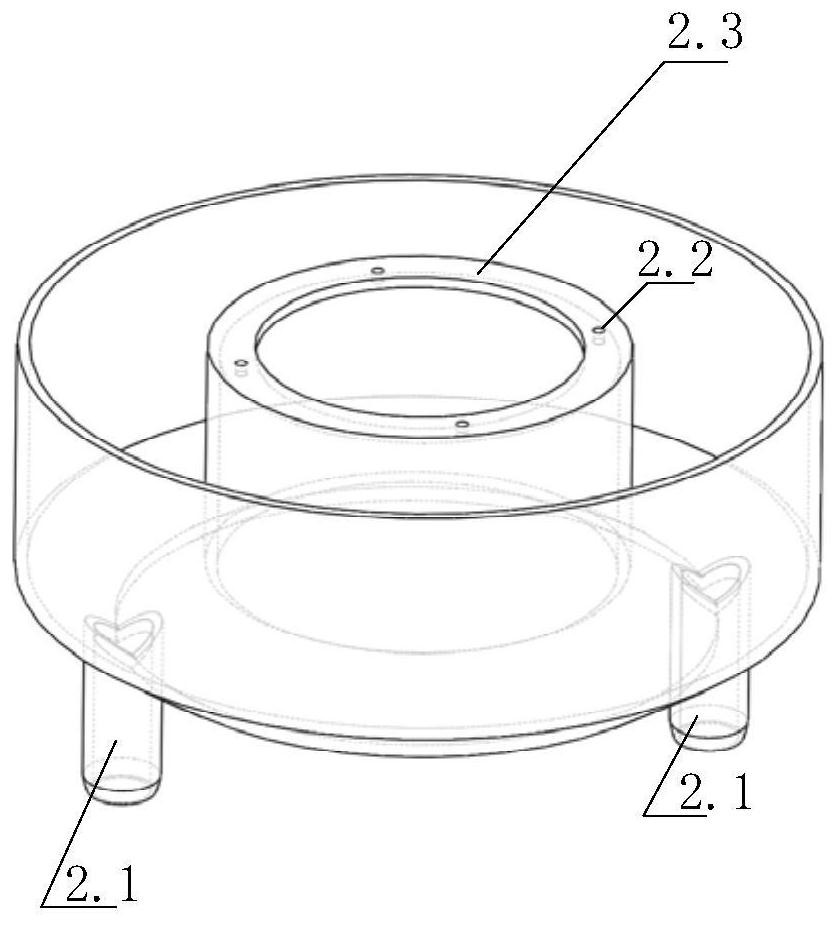

[0030] Such as figure 1 As shown, the device is composed of a Venturi scrubber 1, a liquid film separation part, a liquid film collection part, a constant liquid level water supply system and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com