Network integrated control method and network integrated control device for multichannel equipment

A multi-channel and equipment technology, applied in the general control system, program control, comprehensive factory control, etc., can solve the problems of untreated quality alarms, accidental, and failure to achieve the overall quality of the packaging production line, and eliminate the human negligence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

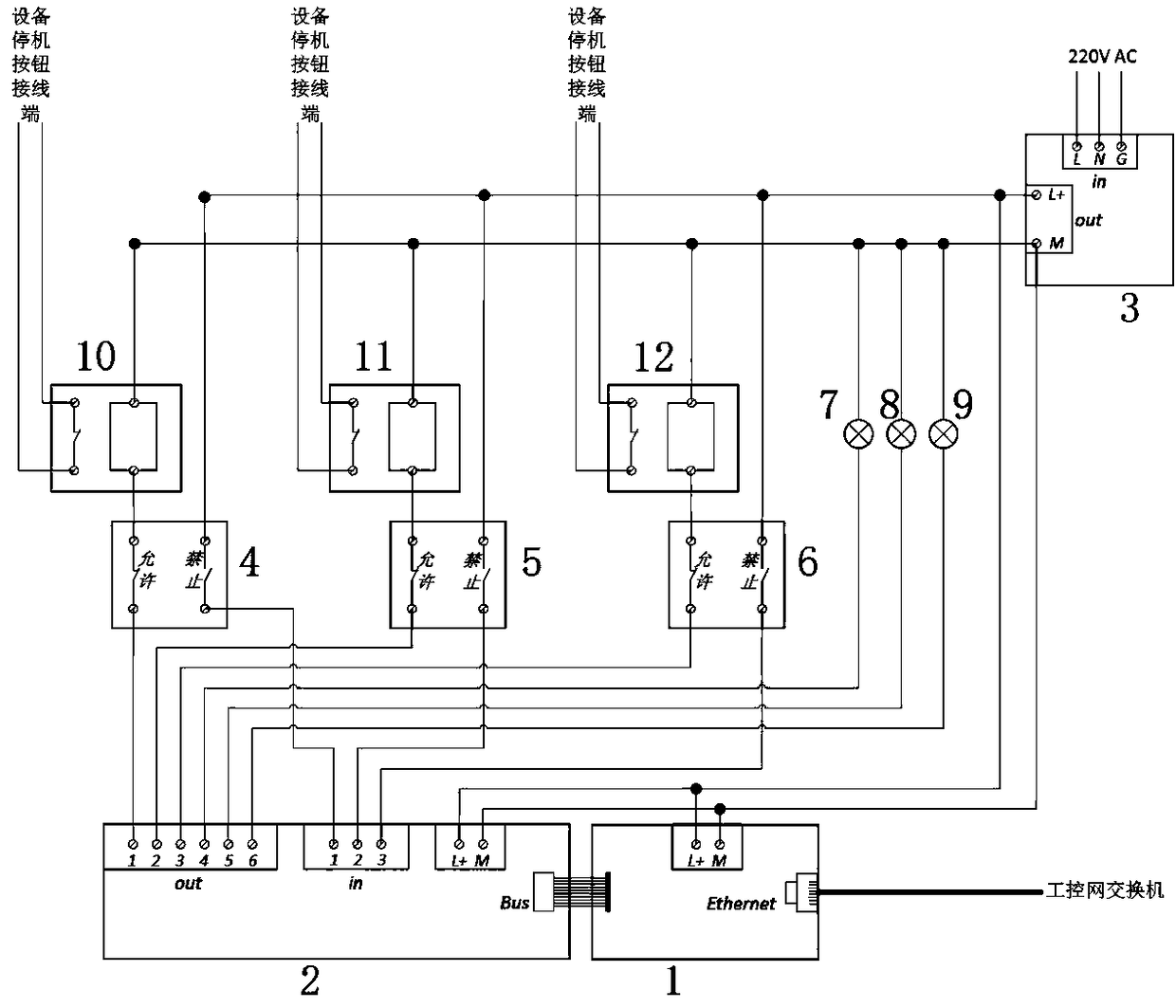

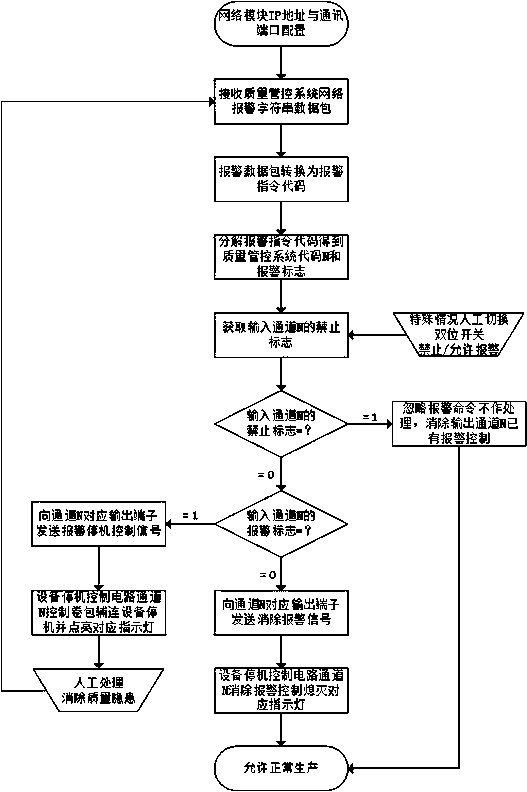

[0027] Attached below Figure 1-2 A method and device for network joint control of multi-channel equipment provided by the present invention are further described.

[0028] The present invention can communicate with a plurality of quality control systems to realize the network alarm joint control of the package auxiliary equipment, and the number of joint control channels can be increased or decreased according to the number of specific quality control systems. Taking the ZJ17-YF17-ZB45 wrapping unit as an example, at present, this model has three quality control systems: the equipment process quality parameter control system, the process path control system, and the production auxiliary material control system. Three-channel network alarm joint control of connected equipment. It is stipulated that the codes of the equipment process quality parameter control system, process path control system, and production auxiliary material control system are 1, 2, and 3 respectively, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com