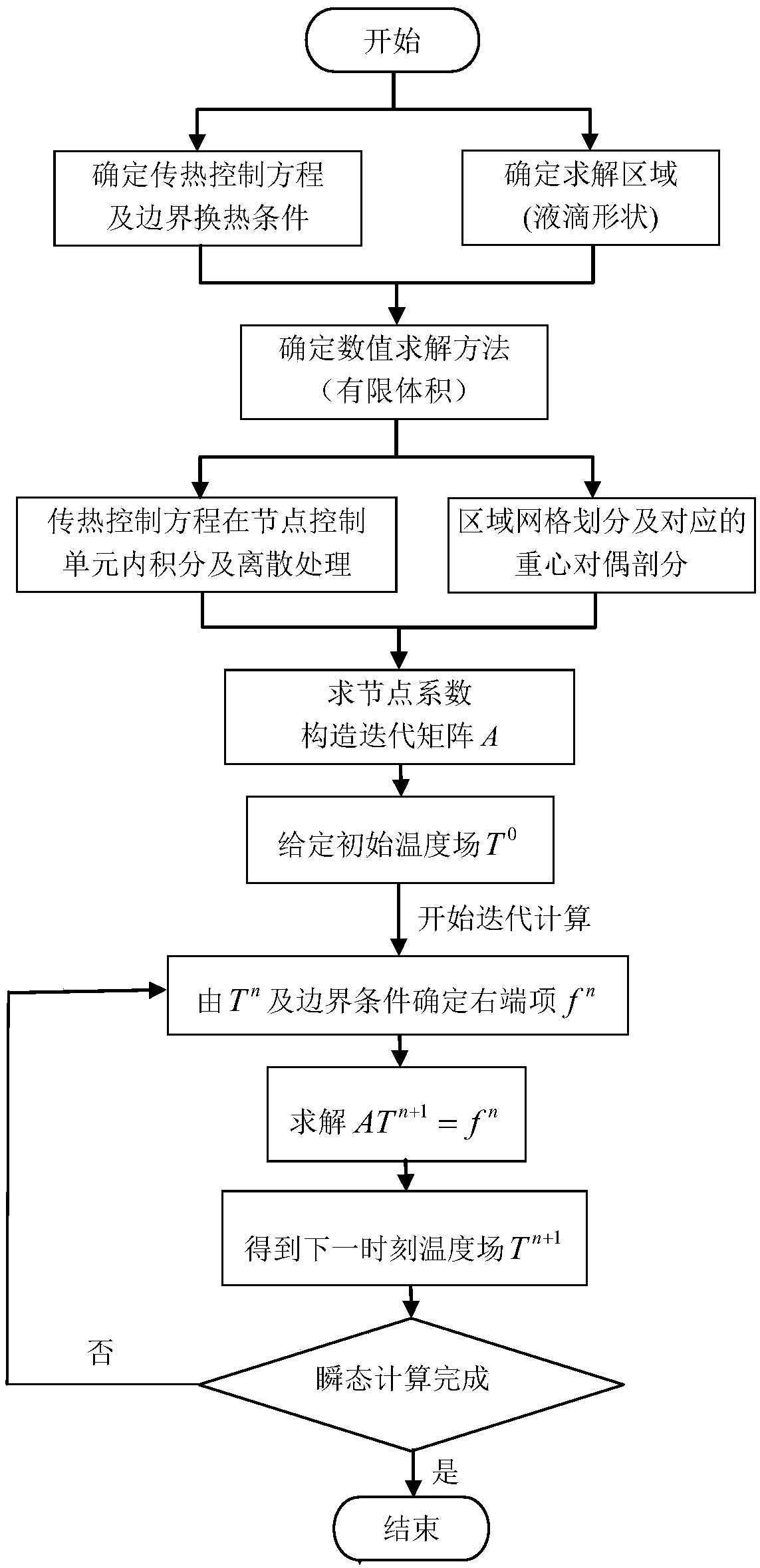

Numerical calculation method for heat transfer of electrostatically suspended liquid alloys

A technology of electrostatic suspension and liquid alloy, which is applied in the numerical calculation of heat transfer of electrostatic suspension liquid alloy, and the heat transfer calculation field of regular and irregular shape alloy droplets, which can solve the problem of influence, uneven temperature distribution of droplets, and inability to obtain liquid state Alloy internal temperature field distribution and changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

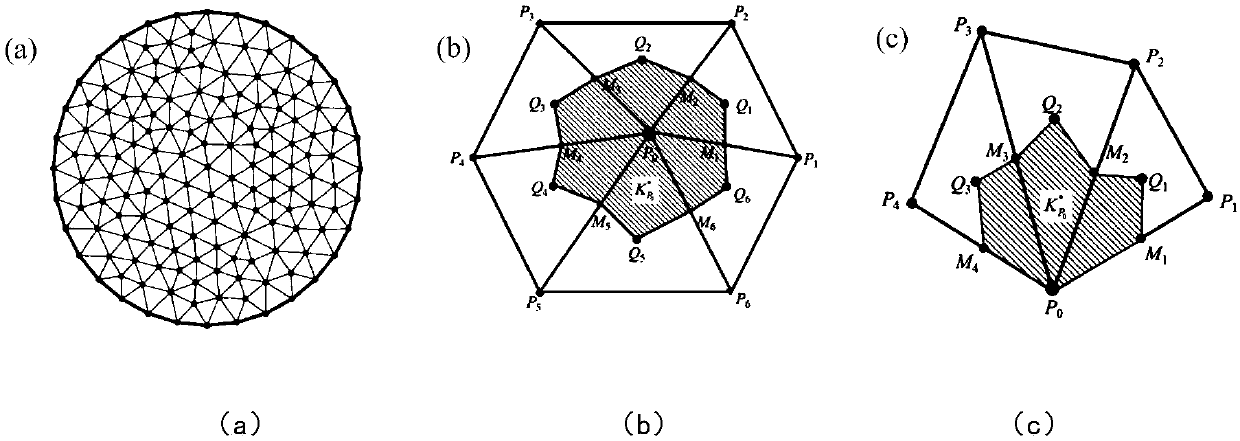

Method used

Image

Examples

Embodiment Construction

[0088] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

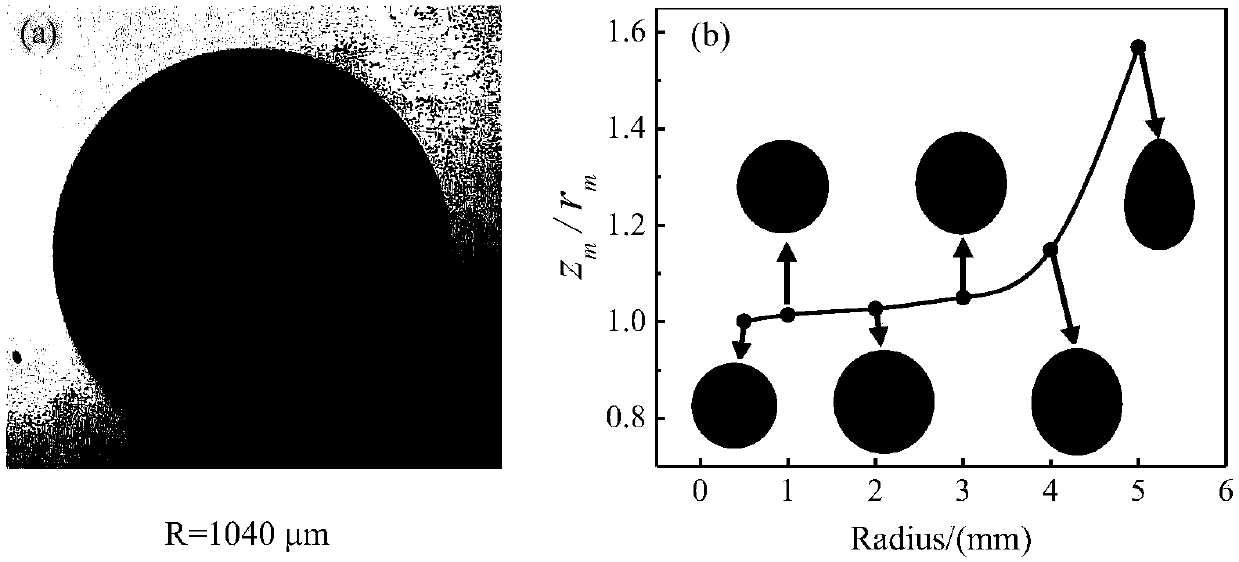

[0089] 1. Determine the geometric shape of the droplet, and use its front view as the calculation solution area:

[0090] The actual form is obtained through experiments or the simulated form is obtained by calculation, such as figure 2 .

[0091] Electrostatic suspension alloy droplet diameter 0.1 ~ 10mm, z m / r m =1~1.57, where z m and r m are the maximum values of the vertical and horizontal diameters of the droplet, respectively.

[0092] 2. Establish heat transfer governing equation and boundary heat exchange conditions:

[0093] (1) The governing equation of droplet heat transfer is:

[0094]

[0095] Among them, T(x, y, z; t) is the temperature field function about the position (x, y, z) and time t, u is the internal flow velocity of the droplet, ρ, c, λ are the droplet density, specific heat, Thermal Conductivity.

[0096] Because the inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com