Pulse resistor and method for adjusting the resistance of the pulse resistor

A technology of pulse resistance and resistance adjustment, used in resistors, resistor manufacturing, thick film resistors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

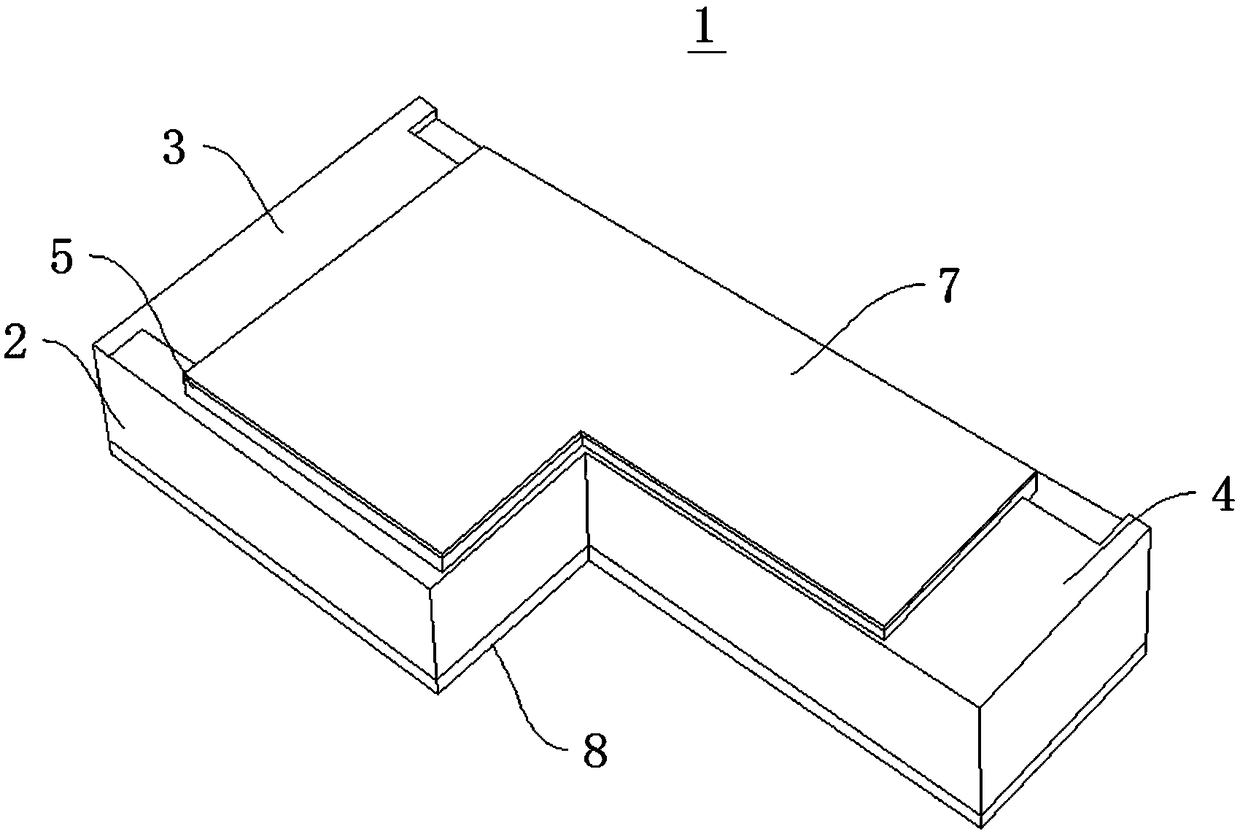

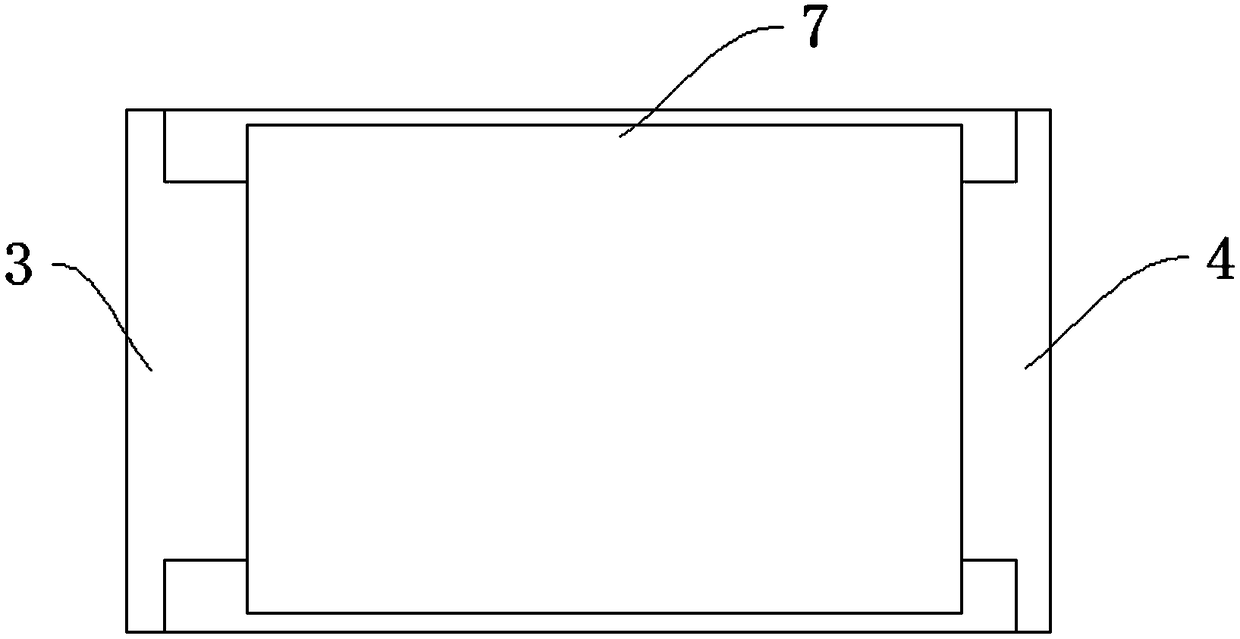

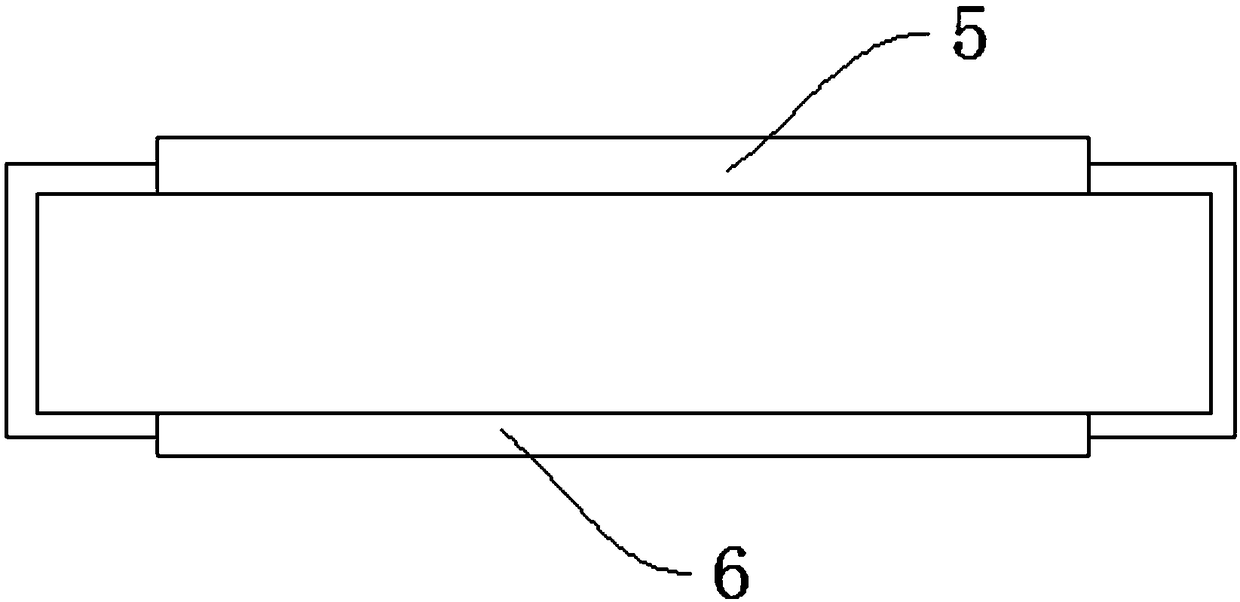

[0042] Please refer to figure 1 , with reference to Figure 2 to Figure 4 , the embodiment of the present invention provides a pulse resistor 1, which adopts a pulse resistance adjustment method to adjust resistance.

[0043] Wherein, the pulse resistor 1 includes a ceramic base 2, a first electrode 3, a second electrode 4, a first resistor 5, a second resistor 6, a first glass layer 7 and a second glass layer 8; the ceramic base 2 has a relatively The first side end and the second side end, the first electrode 3 is covered on the first side end, and the second electrode 4 is covered on the second side end; the ceramic substrate 2 has an opposite first surface and a second surface, and the second electrode 4 is covered on the second side end; A resistor body 5 is installed on the first surface, and a second resistor body 6 is installed on the second surface; the first glass layer 7 is installed on the first resistor body 5, and the second glass layer 8 is installed on the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com