Crane trolley end beam rib plate automatic welding device

A lifting trolley, automatic welding technology, applied in auxiliary devices, welding equipment, welding equipment and other directions, can solve the problems of low welding efficiency and poor welding quality, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

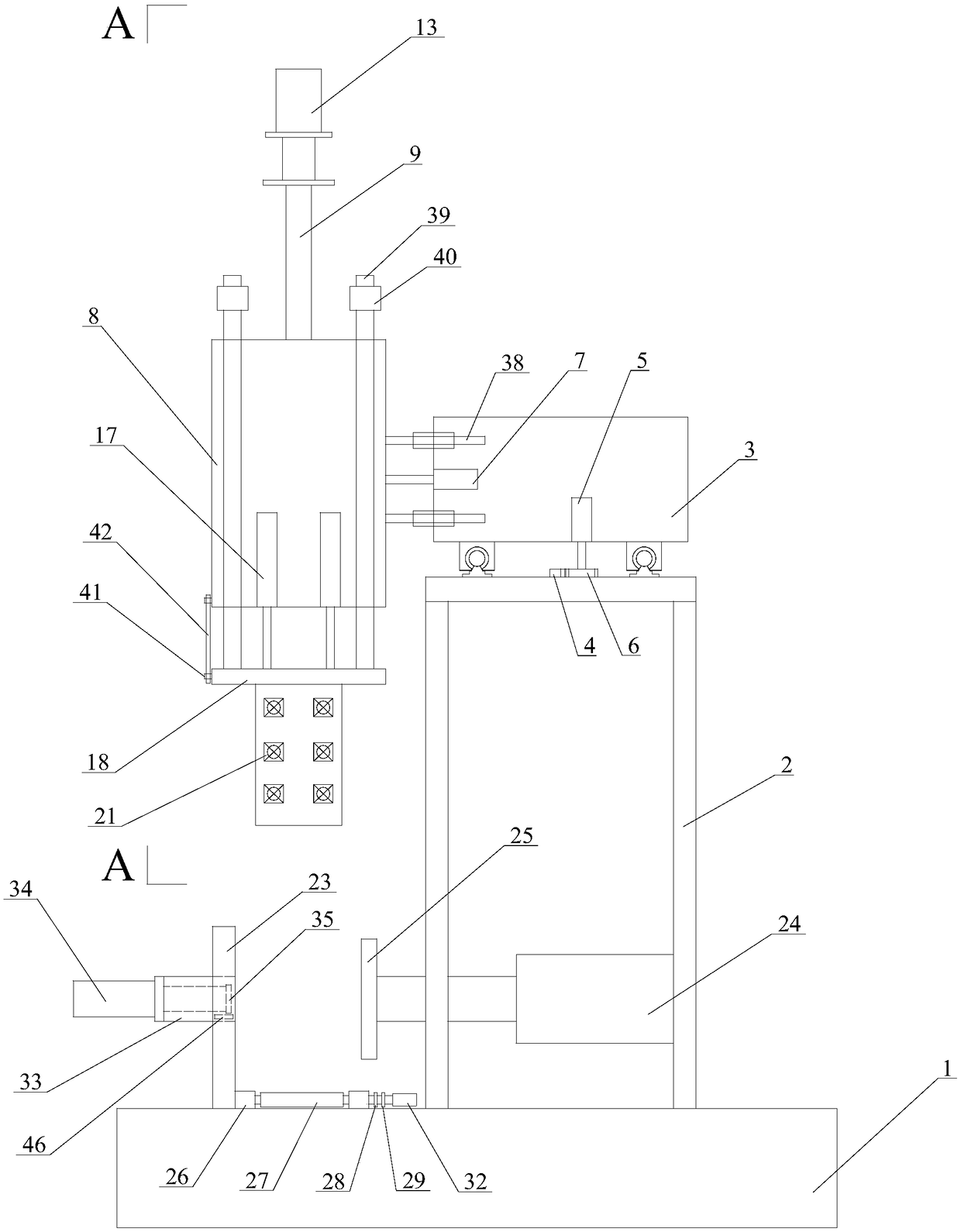

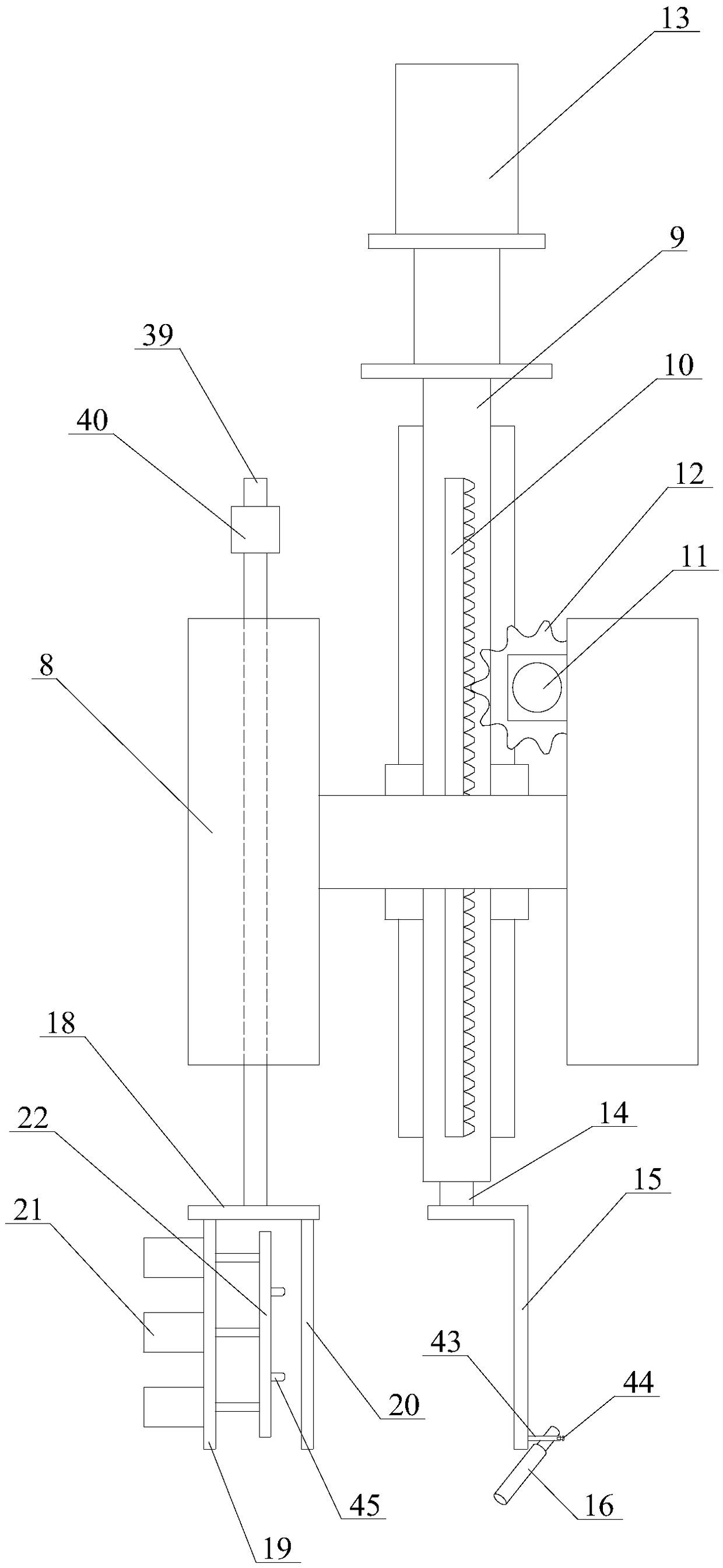

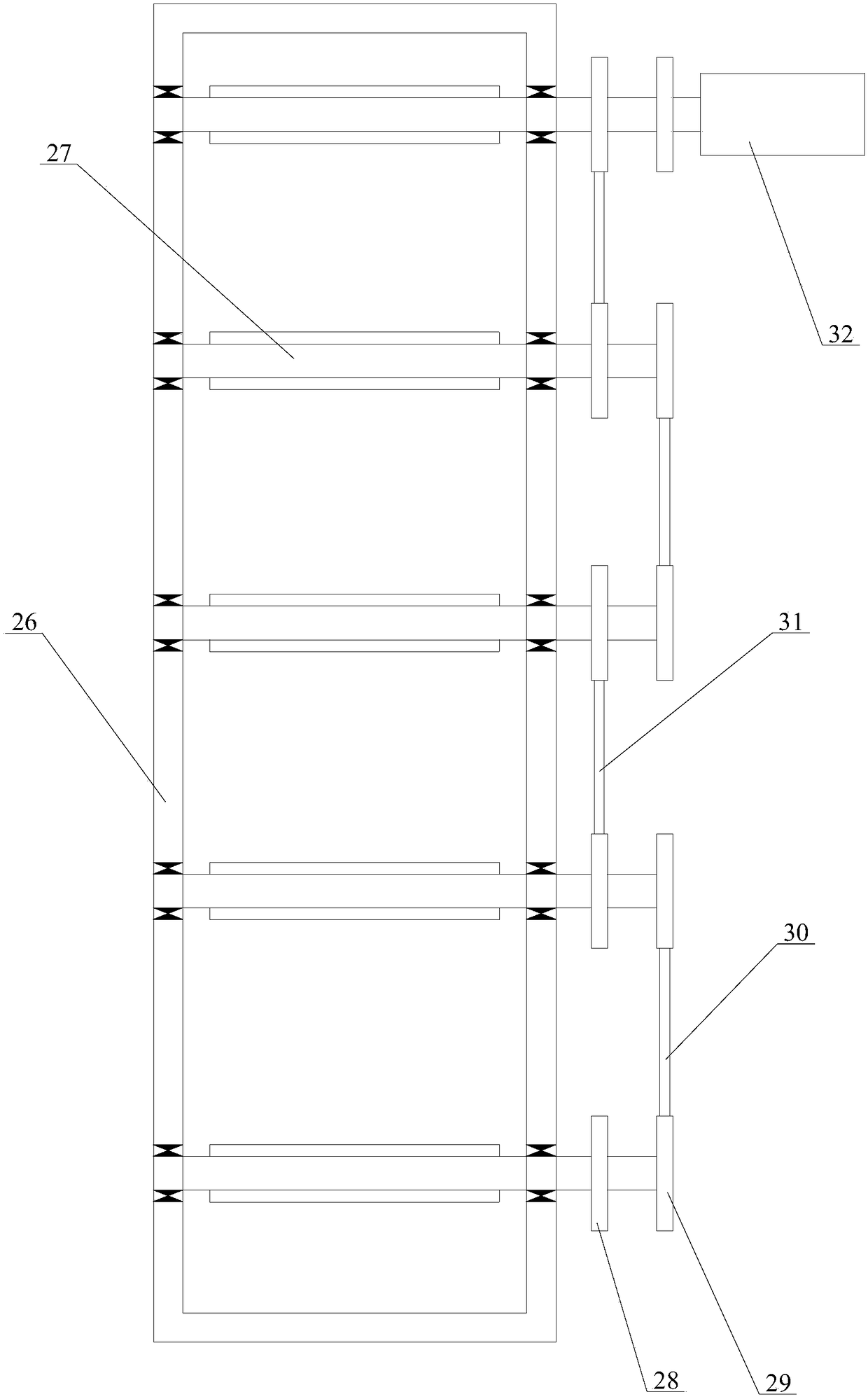

[0019] In order to make the objectives, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention are further described in detail below with reference to the accompanying drawings.

[0020] like figure 1 , figure 2 As shown, the present invention provides an automatic welding device for end beam ribs of a hoisting trolley, comprising a base 1, a mounting table 2 is fixedly connected to the base 1, a welding gun manipulator driving device is arranged on the mounting table 2, and a base 1 is mounted on the base 1. A rib plate positioning device is provided; the welding gun manipulator driving device includes a horizontal driving device and a vertical driving device respectively used to drive the welding gun manipulator to move, and the horizontal driving device includes a fixing frame 3 arranged above the installation table 2. The bottom end of 3 is slidably connected to the table surface of the mounting table 2. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com