Air energy phase change material mass concrete temperature control system and construction method thereof

A technology of large-volume concrete and phase-change materials, which is applied in the processing of building materials, construction, and building construction, and can solve problems such as large temperature differences between the internal and external temperatures of concrete, uneven distribution of concrete temperature fields, and prone to structural cracks. , to achieve uniform and stable temperature field distribution, improve temperature control efficiency, and reduce circulating water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention are described in detail below through the examples, and the following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations to the technical solutions of the present invention.

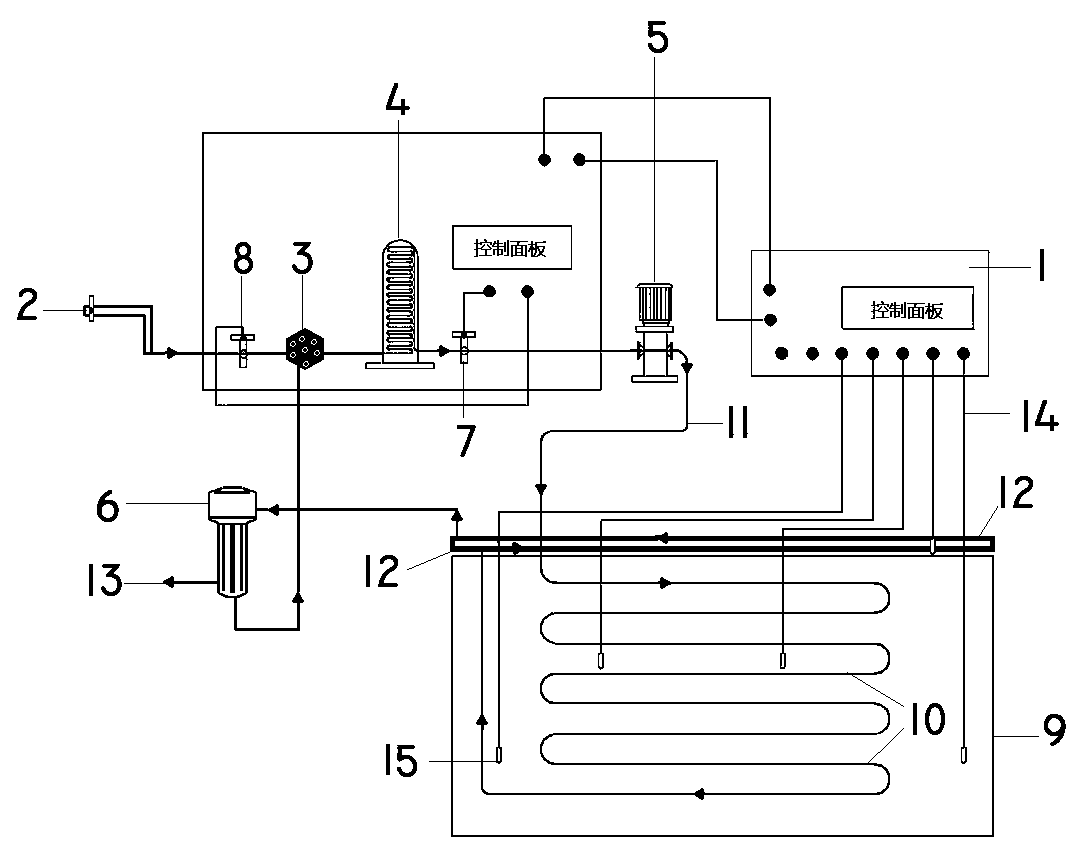

[0043] Such as figure 1 As shown, one aspect of the present invention provides an air energy phase change material mass concrete temperature control system. The mass concrete 9 is prepared by mixing cement with a low heat of hydration, and specifically includes an intelligent temperature control induction adjustment device, a temperature control phase change A material aqueous solution delivery pipeline, a phase change material doser 3 , at least one air energy refrigeration device 4 , a booster pump 5 and a filtering device 6 . Among them, the intelligent temperature control induction adjustment device includes a temperature control dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com