Method for precision treatment of NMP recovery and purification in production of lithium battery

A lithium battery, sophisticated technology, applied in organic chemistry and other directions, can solve the problems of low NMP purity, environmental pollution, waste of NMP raw materials, etc., and achieve the effect of improving utilization, improving elution rate, and small emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

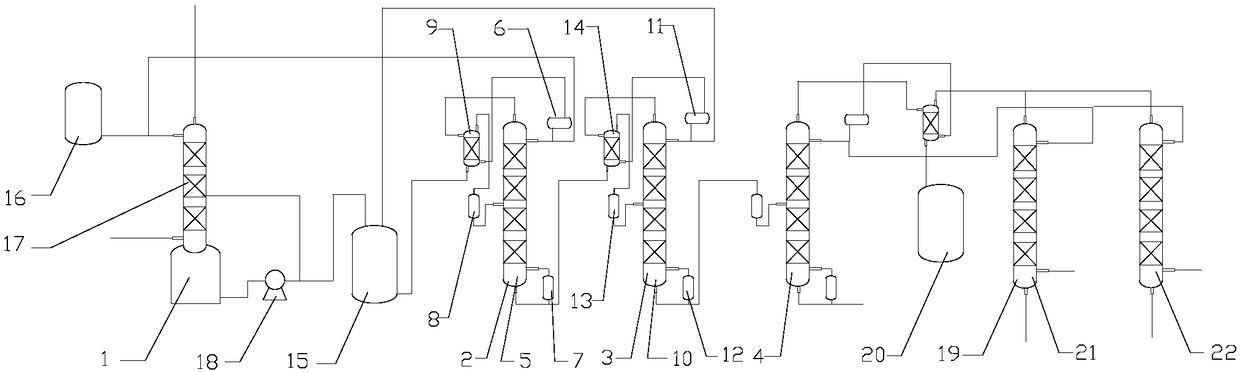

Image

Examples

Embodiment 1

[0052] The NMP recovery and purification precision treatment method described in this embodiment uses the above-mentioned NMP recovery and purification precision treatment device, comprising the following steps:

[0053] Sorbent preparation

[0054] Add 2wt% attapulgite clay and 60mL toluene to the three-necked flask, then add 10wt% acrylamide, then add azobisisobutyronitrile as an initiator, react at 70 degrees for 6h, and separate the product by filtration with toluene , absolute ethanol and deionized water to obtain polyacrylamide-attapulgite clay composite adsorption material. Take 40 parts of activated carbon, 18 parts of polyacrylamide-attapulgite clay composite material, 15 parts of diatomaceous earth and 10 parts of MCM-41 mesoporous molecular sieve, and physically mix them uniformly to obtain an adsorbent.

[0055] The first step is to use water as the absorbent and use the absorption tower to recover the NMP waste gas volatilized during the production of lithium bat...

Embodiment 2

[0061] The NMP recovery and purification precision treatment method described in this embodiment uses the above-mentioned NMP recovery and purification precision treatment device, comprising the following steps:

[0062] Sorbent preparation

[0063] Add 5wt% attapulgite clay and 50mL toluene to the three-necked flask, then add 15wt% acrylamide, then add azobisisobutyronitrile as an initiator, react at 70°C for 6h, and separate the product by filtration with toluene , absolute ethanol and deionized water to obtain polyacrylamide-attapulgite clay composite adsorption material. Take 60 parts of activated carbon, 32 parts of polyacrylamide-attapulgite clay composite material, 25 parts of diatomaceous earth and 25 parts of SBA-15 molecular sieve, and physically mix them uniformly to obtain an adsorbent.

[0064] The first step is to use water as the absorbent and use the absorption tower to recover the NMP waste gas volatilized during the production of lithium battery separators o...

Embodiment 3

[0070] The method for NMP recovery and purification precision treatment described in the present embodiment uses the above-mentioned device for NMP recovery and purification precision treatment, comprising the following steps:

[0071] Sorbent preparation

[0072] Add 8wt% attapulgite clay and 70mL of toluene to the three-necked flask, then add 12wt% acrylamide, and then add azobisisobutyronitrile as an initiator, react at 70 degrees for 6h, and filter and separate the product with toluene , absolute ethanol and deionized water to obtain polyacrylamide-attapulgite clay composite adsorption material. Take 50 parts of activated carbon, 24 parts of polyacrylamide-attapulgite clay composite material, 18 parts of diatomaceous earth and 18 parts of MCM-41 mesoporous molecular sieve, and physically mix them uniformly to obtain an adsorbent.

[0073] The first step is to use water as the absorbent and use the absorption tower to recover the NMP waste gas volatilized during the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com