Method and equipment for NMP recovery and heat-pump rectification in lithium electric production

A technology of heat recovery and rectification, applied in separation methods, heat recovery systems, distillation energy recovery, etc., can solve the problems of waste of NMP raw materials, low NMP purity, environmental pollution, etc., to improve utilization and reduce waste liquid discharge. , the effect of small emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

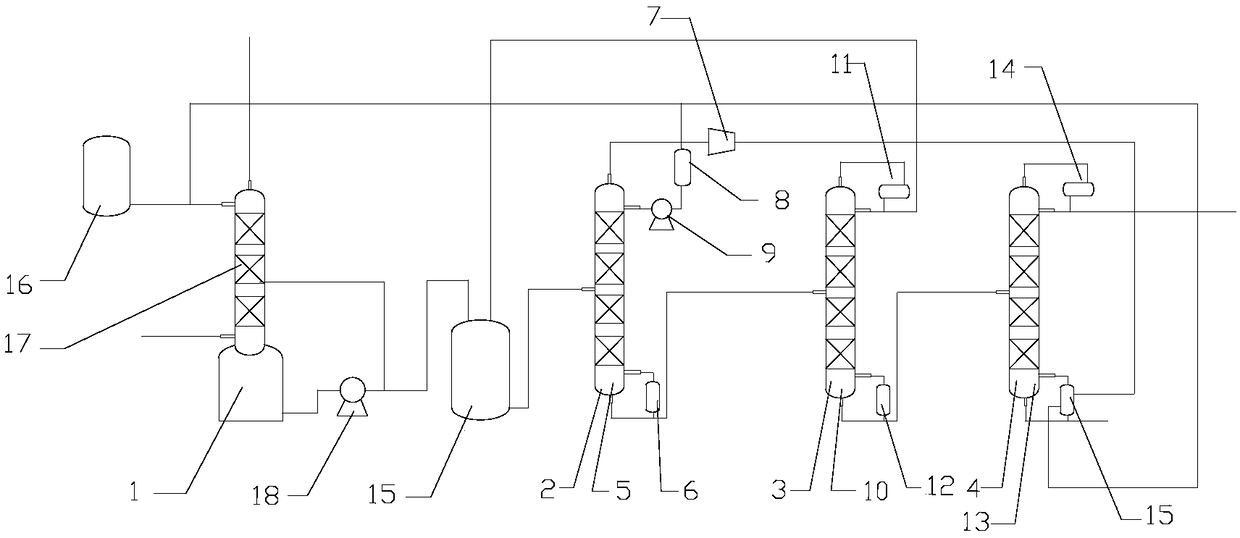

[0046] The method for NMP recovery heat pump rectification described in this embodiment uses the above-mentioned NMP recovery heat pump rectification equipment, comprising the following steps:

[0047] The first step is to use water as the absorbent and use the absorption tower to recover the NMP waste gas volatilized during the production of lithium battery separators or electrode materials. The operating pressure is 101.3kPa, the operating temperature is 20 degrees, and the liquid-gas ratio is about 0.72. The NMP is obtained after treatment. Waste liquid;

[0048] In the second step, the NMP waste liquid is input into the dehydration rectification tower 2 for separation. The light component gas at the top of the tower obtained after separation in the distillation tower 2 is mainly water vapor, and the concentration of NMP is less than 500mg / L. The light component gas at the top of the rectification tower 2 is pressurized and heated by the compressor 7, and the low-grade hea...

Embodiment 2

[0052] The method for NMP recovery heat pump rectification described in this embodiment uses the above-mentioned NMP recovery heat pump rectification equipment, comprising the following steps:

[0053] The first step is to use water as the absorbent and use the absorption tower to recover the NMP waste gas volatilized during the production of lithium battery separators or electrode materials. The operating pressure is 101.3kPa, the operating temperature is 20 degrees, and the liquid-gas ratio is about 0.72. The NMP is obtained after treatment. Waste liquid;

[0054]In the second step, the NMP waste liquid is input into the dehydration rectification tower 2 for separation. The light component gas at the top of the tower obtained after separation in the distillation tower 2 is mainly water vapor, and the concentration of NMP is less than 450mg / L. The light component gas at the top of the rectification tower 2 is pressurized and heated by the compressor 7, and the low-grade heat...

Embodiment 3

[0058] The method for NMP recovery heat pump rectification described in this embodiment uses the above-mentioned NMP recovery heat pump rectification equipment, comprising the following steps:

[0059] The first step is to use water as the absorbent and use the absorption tower to recover the NMP waste gas volatilized during the production of lithium battery separators or electrode materials. The operating pressure is 101.3kPa, the operating temperature is 20 degrees, and the liquid-gas ratio is about 0.72. The NMP is obtained after treatment. Waste liquid;

[0060] In the second step, the NMP waste liquid is input into the dehydration rectification tower 2 for separation. The light component gas at the top of the tower obtained after separation in the distillation tower 2 is mainly water vapor, and the concentration of NMP is less than 500mg / L. The light component gas at the top of the rectification tower 2 is pressurized and heated by the compressor 7, and the low-grade hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com