Component surface coating peeling method and device

A surface coating and component technology, applied in the field of surface coating peeling of parts, can solve problems such as easy to severely corrode coatings, increase the difficulty of peeling, and environmental pollution by chemical peeling methods, so as to overcome complexity and facilitate precise control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

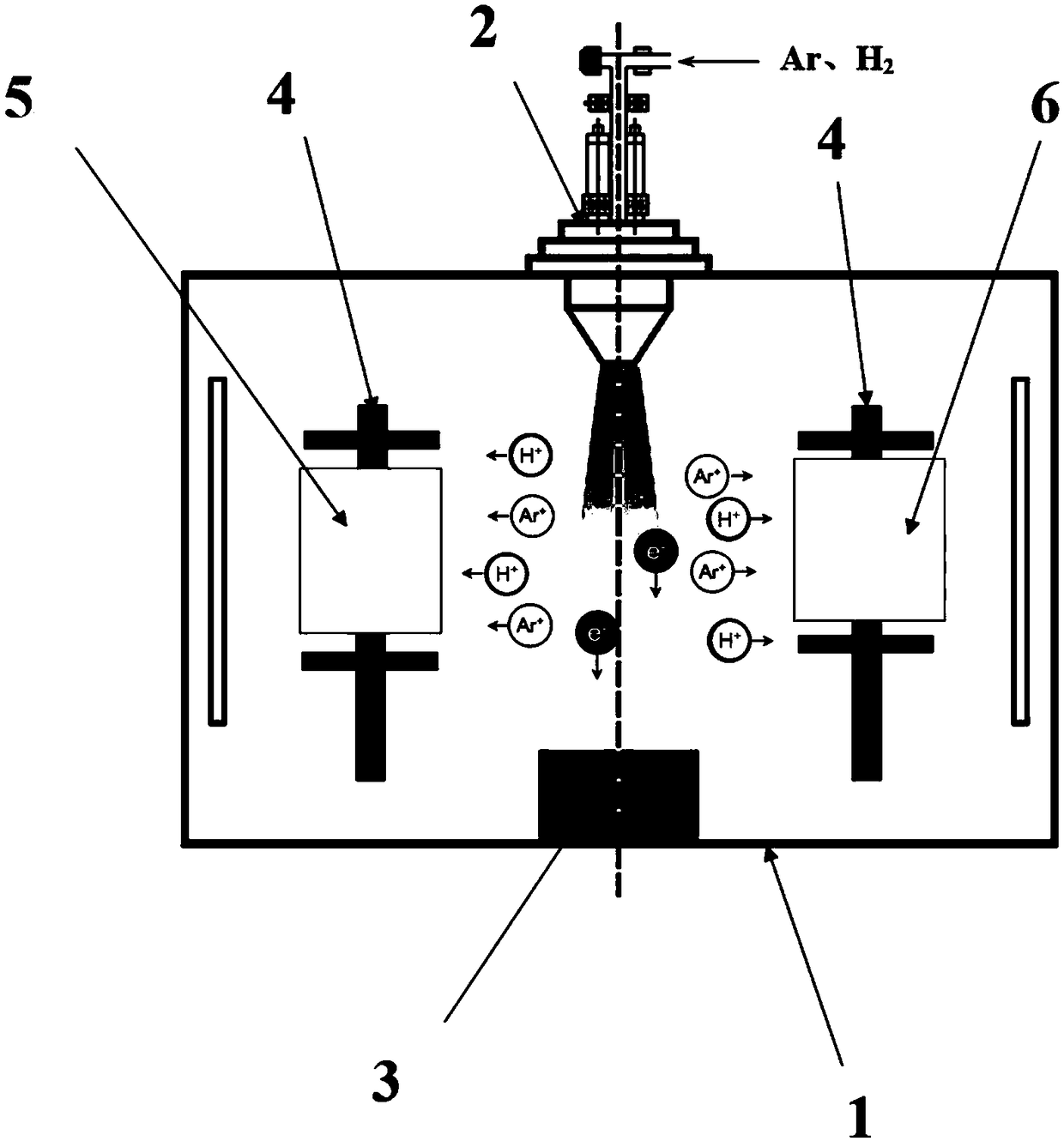

Image

Examples

Embodiment 1

[0056] In order to make the coating easier to peel off, in this embodiment, Ar gas and H 2 After degassing, the vacuum chamber 1 is preheated to a certain temperature to activate the ion energy of the coating, so that the coating atoms are more likely to get rid of the shackles of the coating matrix and peel off after being bombarded by gas ions.

Embodiment 2

[0058] In this example, on the basis of Example 1, the preheating temperature is controlled within the range of 300-400°C, and the heating time is controlled within 50 minutes to 70 minutes, so that the ion energy of the coating can be fully activated and maintained at Best state.

Embodiment 3

[0060] In this embodiment, in order to make the peeling process carry out in a stable vacuum environment, after vacuuming in step A, ensure that the pressure in the vacuum chamber 1 is less than 5×10 -2 Pa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com