Novel water silk floss machine

A water silk floss machine, a new type of technology, is applied in the production of silk from silkworm cocoons, which can solve the problems of gas pipe explosion, insufficient hot water dissolution, waste of time, etc., and achieve the effect of convenient separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

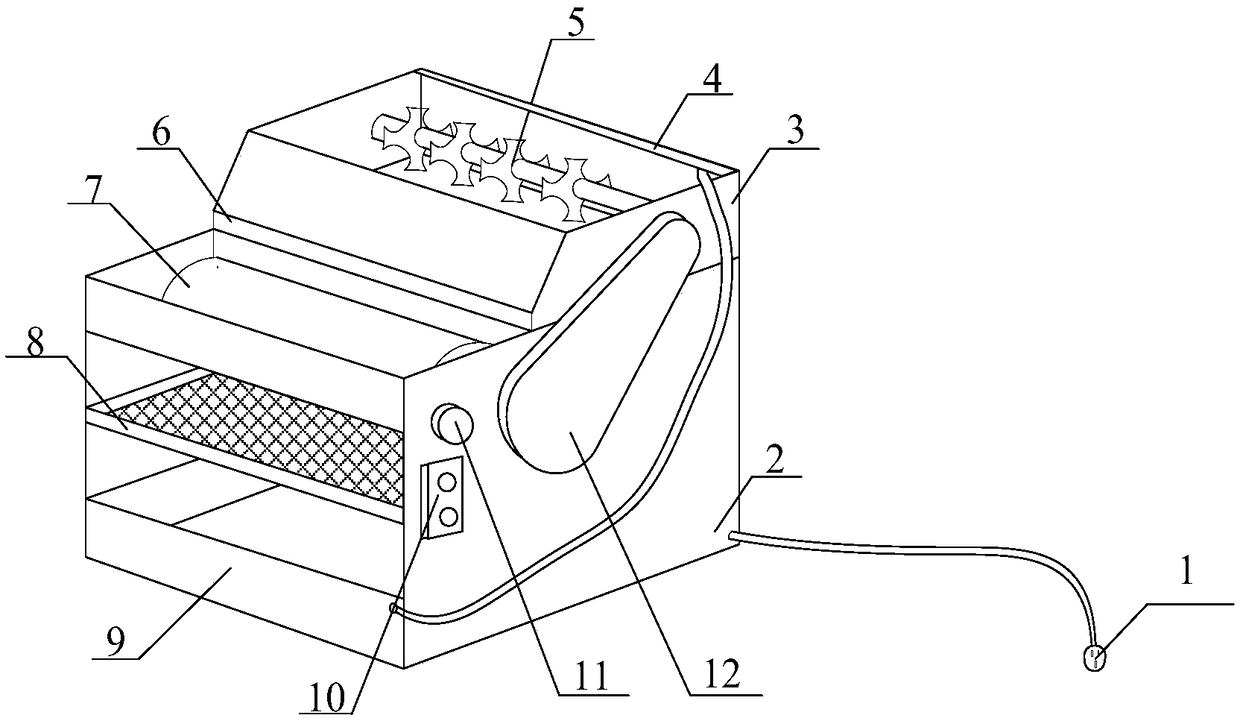

[0025] as attached figure 1 to attach Figure 6 shown

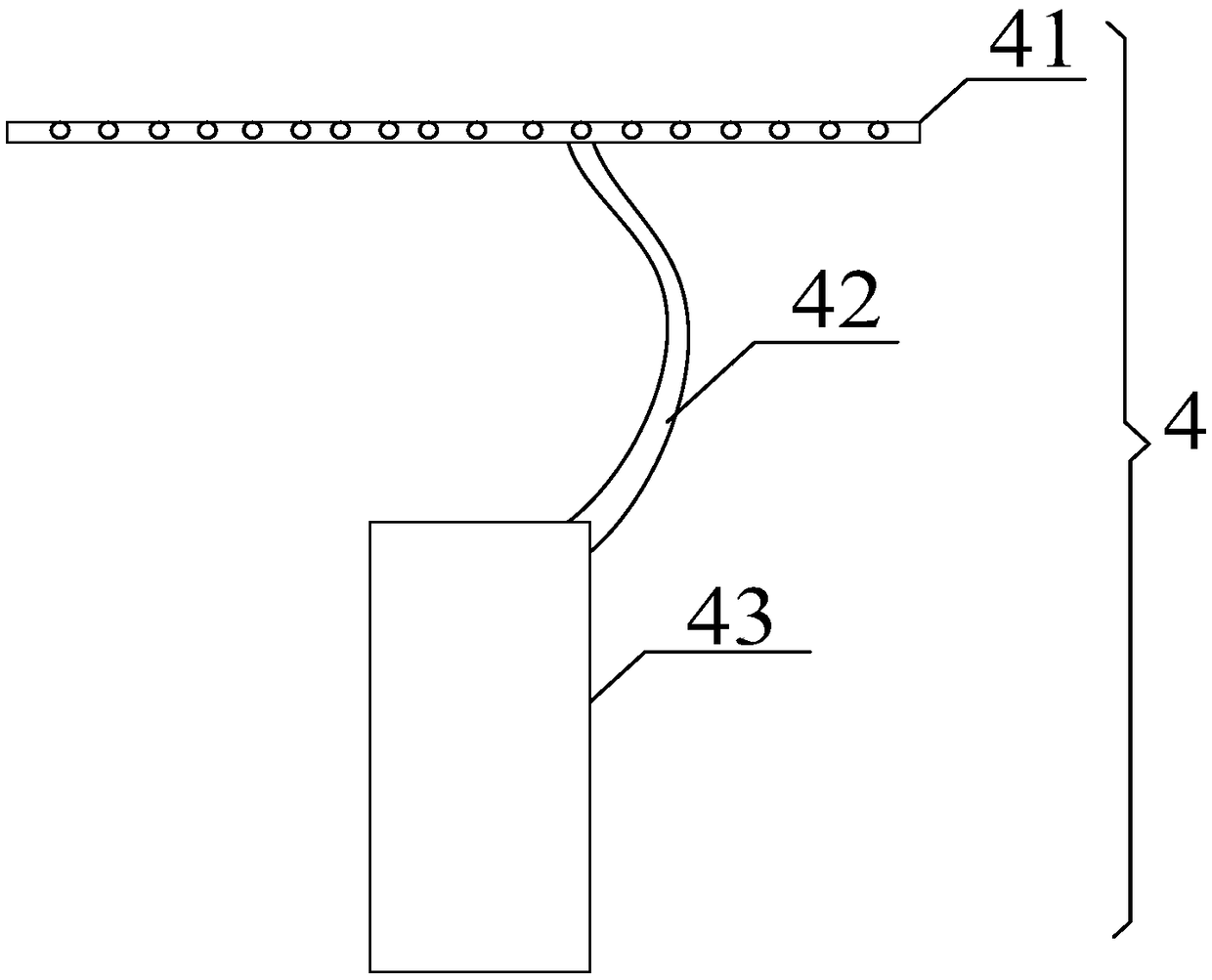

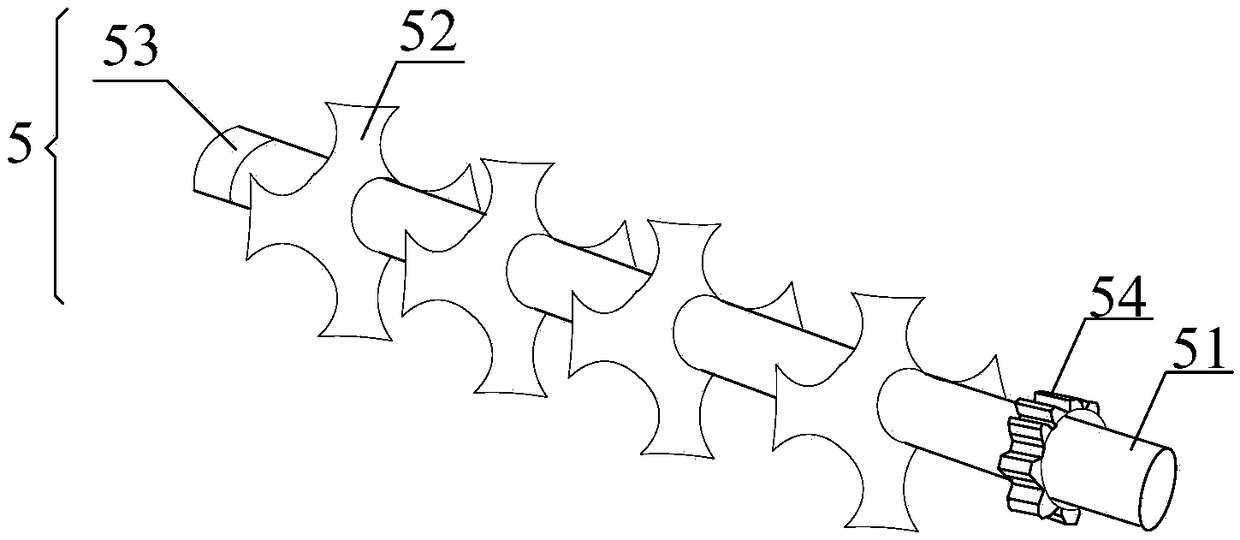

[0026] The invention provides a new type of water silk cotton machine, including a power plug 1, a body 2, a stirring tank 3, a water spray device 4, a stirring device 5, a discharge port 6, a licker-in roller 7, a filter screen 8, a heating water tank device 9, a switch 10, emergency stop 11 and transmission mechanism 12, the power plug 1 is connected to the switch 10 through the power line, and connected in series with the emergency stop 11; the stirring tank 3 is installed on the top of the body 2 by welding; The water device 4 is installed on the rear side of the upper part of the stirring tank 3 through screw connection; the stirring device 5 is connected in the stirring tank 3 through a shaft, and is meshed with the transmission mechanism 12 through gears; the discharge port 6 is opened in the stirring tank 3. The lower part of the front side; the licker-in roller 7 is connected in the body 2 through a shaft, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com