Double-plastic reinforced composite winding pipe

A technology of reinforced composite and wound pipes, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc. It can solve the problems that full PE pipes cannot meet the requirements of high strength, high production costs, and high prices of PE materials, and achieve savings materials, avoiding injuries, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

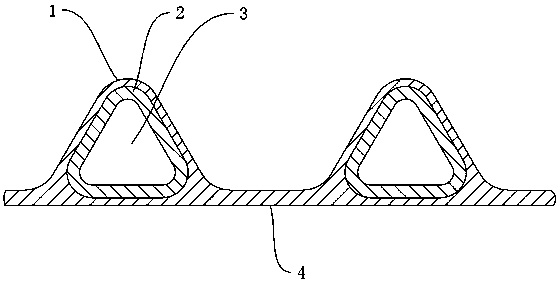

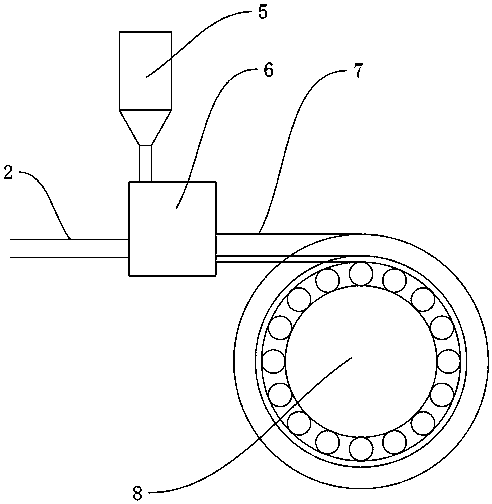

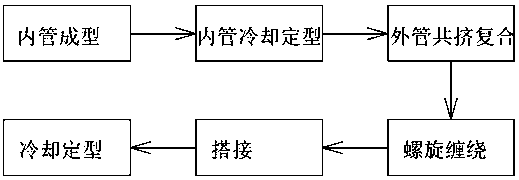

[0028] Embodiment 1: A kind of double-plastic reinforced composite winding pipe (see figure 1 ), the winding tube has a smooth inner wall 4 and a spiral ring-shaped protrusion with a hollow structure. The winding tube is helically wound by a winding unit 7 with a hollow cavity 3 and overlapped on adjacent sides. The winding unit includes PP. The circumferentially closed inner tube 2 and the circumferentially closed outer tube 1 made of PE, the two sides of the outer tube have overlapping edges 9, and the winding unit is made of the inner tube at a state lower than the melting temperature and the PE in the molten state. It is extruded and compounded. The outer tube wraps tightly around the inner tube. After spiral winding, the adjacent sides of the outer tube overlap to form a smooth inner wall, and the inner tube forms a spiral ring-shaped protrusion with a hollow structure.

[0029] The cross-section of the inner tube is a rounded triangle shape. When the winding unit is spir...

Embodiment 2

[0035] Embodiment 2: A double-plastic reinforced composite winding pipe. The difference from Embodiment 1 is that there are concave recesses distributed on the inner pipe at intervals. The recesses are long strips, and the length direction of the recesses is along the inner pipe. The circumferential direction is perpendicular to the axis of the inner tube, the distribution direction of the recesses is along the axis of the inner tube, and the recesses are distributed at equal intervals. The concave part is formed by the rotary extrusion of the extrusion wheel with the convex part on the outer circumference of the inner tube before co-extrusion compounding. The linear speed of the extrusion wheel is the same as the advancing speed of the co-extrusion composite of the inner tube, the extrusion wheel is arranged on the side of the inner tube, and the rotation axis of the extrusion wheel is perpendicular to the axis of the inner tube. In this embodiment, the cross-section of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com