Satellite cellular board sample preparation device

A technology of sample preparation and honeycomb plate, applied in the preparation of test samples, measuring devices, sampling, etc., can solve problems such as pressure changes, achieve low cost, good versatility, and improve sample preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The present invention provides a honeycomb panel sample preparation device for satellites, comprising a base 1, a first adjustment assembly, a second adjustment assembly, a pressure plate 6 and a pressure sensor 13, the base 1 is provided with a first support structure, the The pressing plate 6 is installed on the first support structure through the first adjustment assembly, and a first accommodation space 15 is provided between the pressing plate 6 and the base 1, and the first accommodation space 15 is used to place the honeycomb panel sample 14, The pressure sensor 13 is arranged along the circumferential direction of the honeycomb panel sample 14 and is arranged in the first accommodation space 15. The pressure sensor 13 is preferably a digital display pressure sensor, and the sample preparation pressure can be determined by observing the readings of the digital display pressure sensor 13. Accurate control, this device can be applied to normal temperature curing and...

Embodiment 2

[0049] This embodiment is a preferred example of Embodiment 1.

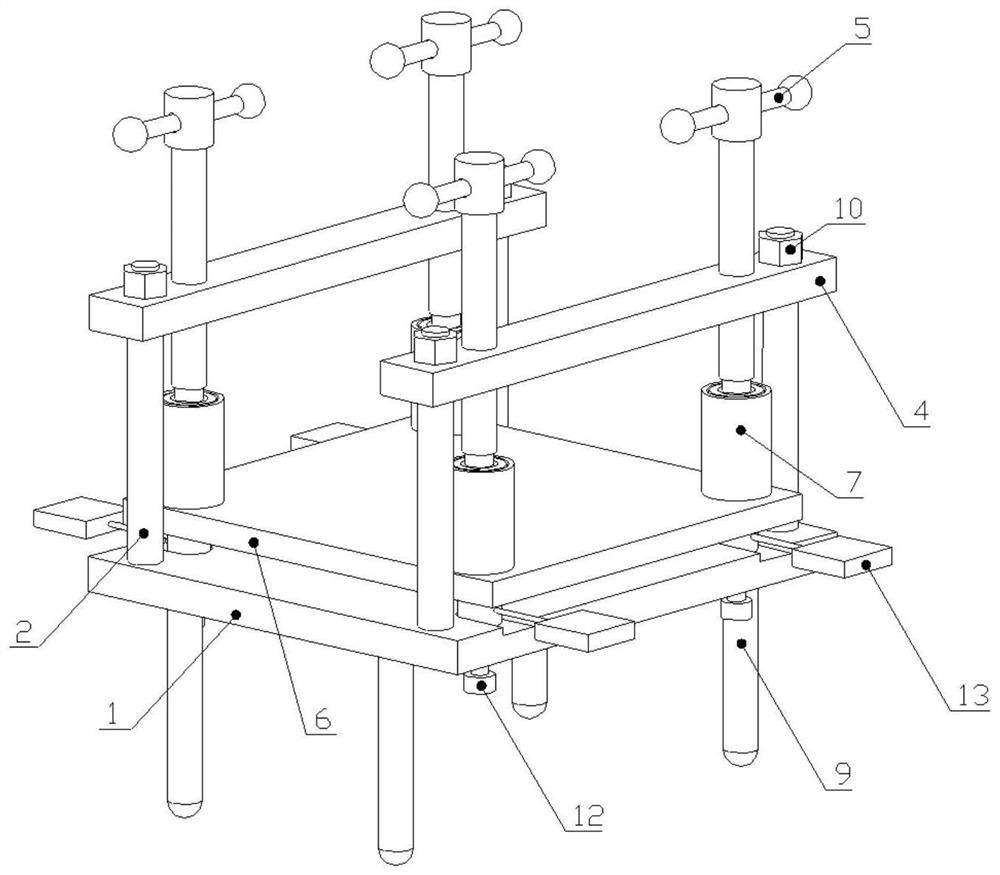

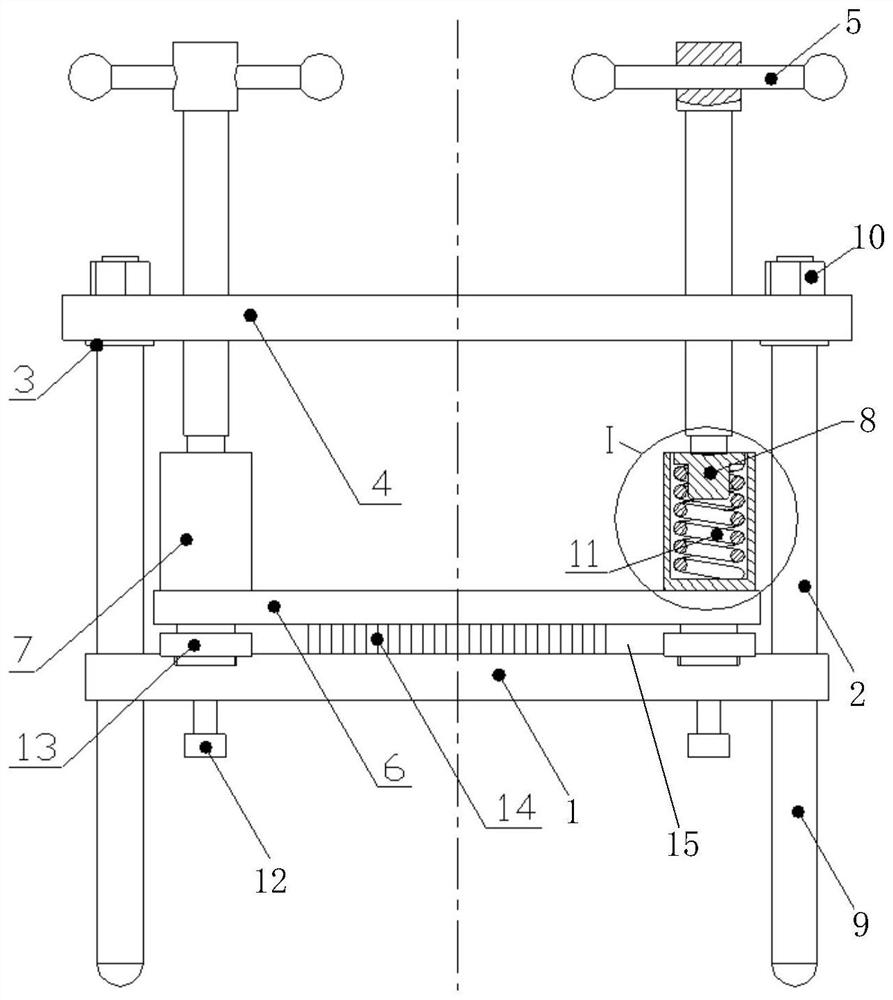

[0050] In this example, if Figure 1 to Figure 5As shown, the first support structure includes four support rods 2, four washers 3, two beams 4 and four hex nuts 10, the bottom ends of the support rods 2 are preferably installed on the base 1 through threaded structures, and the bottom ends of the support rods 2 The top end passes through the washer 3 and the beam 4 in sequence and is fastened by the hex nut 10 to form two mutually symmetrical support frames arranged on both sides of the base 1 .

[0051] In this embodiment, the second support structure adopts a bottom brace 9, and the lower end of the bottom brace 9 is a spherical surface.

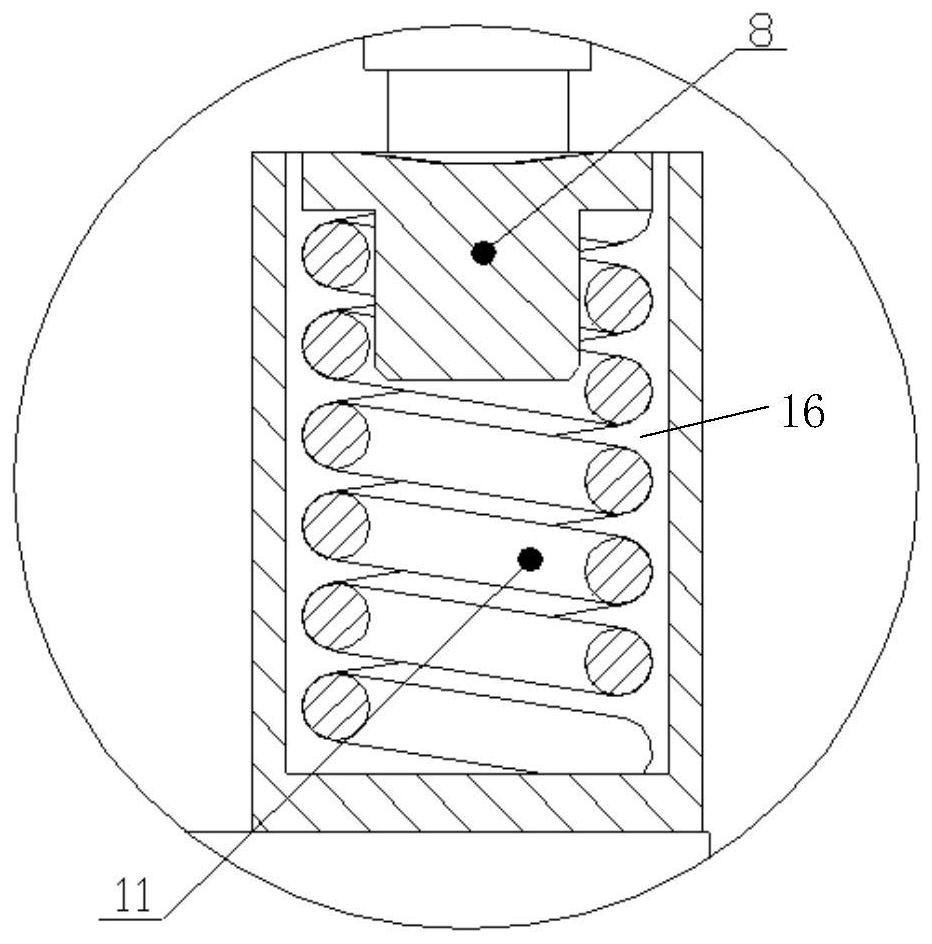

[0052] In this example, if figure 2 , image 3 As shown, the first adjustment assembly includes an adjustment rod 5, a spring cup seat 7, a spring pressure plate 8 and a spring 11, the bottom end of the spring cup seat 7 is connected to the pressure plate 6, and the inte...

Embodiment 3

[0056] This embodiment is another preferred example of Embodiment 1.

[0057] In this embodiment, the pressure area of the honeycomb plate sample 14 is 0.02㎡, and the sample preparation pressure is 0.15MPa. When the readings of the four digital display pressure sensors 13 are all 750N, the pressure of the device reaches the sample preparation pressure. After measurement, the digital display pressure When the reading of the sensor 13 reaches 750N, the deformation of the force-bearing end is 0.1mm. Use a 0.10mm-0.12mm feeler gauge to evenly pad around the upper surface of the honeycomb panel sample 14, and cover the pressure plate 6 according to the pre-installed state.

[0058] In this embodiment, the sum of the weights of the pressing plate 6 , the spring cup holder 7 , the spring pressing plate 8 and the spring 11 is 52N. Slowly tighten the hexagon socket head cap screw 12 to drive the digital display pressure sensor 13 to move upward. In order to ensure that the four digit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Stiffness coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com