MI mineral insulated armored heating cable and metal heat conduction board supporting floor heating system

An armored heating cable, mineral insulation technology, applied in the direction of electric heating system, heating system, heating method, etc., can solve the problems of high cost, low heating efficiency of floor heating, high energy consumption, guarantee the service life and increase the efficiency of the construction area , the effect of the same heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

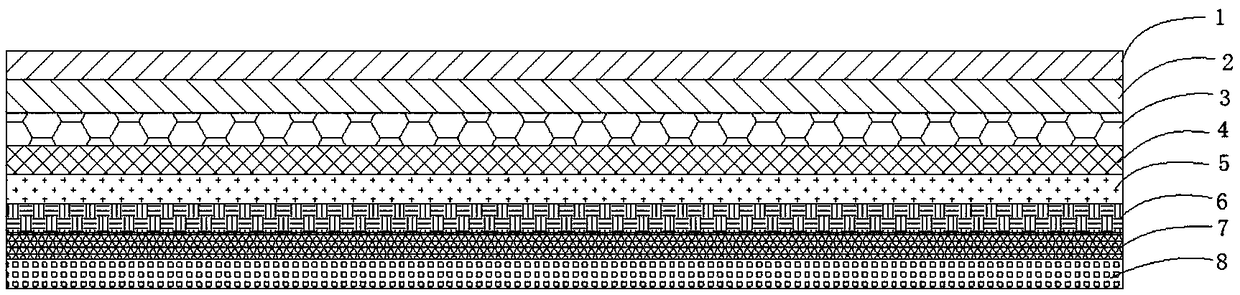

[0022] See figure 1 , a MI mineral insulated armored heating cable and a metal heat conduction plate matching floor heating system disclosed in this embodiment include a moisture-proof layer 8, an insulation board layer 7, a mirror heat reflection film layer 6, and a metal heat conduction plate laid in order from the bottom layer. Layer 5, MI mineral insulated armored heating cable layer 4, support net 3, heat storage layer 2 and ground decoration layer 1; wherein, the thickness of the metal heat conduction plate layer 5 paved on the upper layer of the mirror reflection film 6 is 0.25-0.3mm , the metal heat conduction plate layer 5 fixes the wire through a small metal or plastic clamp, so that the armored heating cable is firmly fixed and attached to the surface of the metal heat conduction plate layer 5, and the heat is fastest and most uniformly transferred to the upper layer for heat storage floor and ground space.

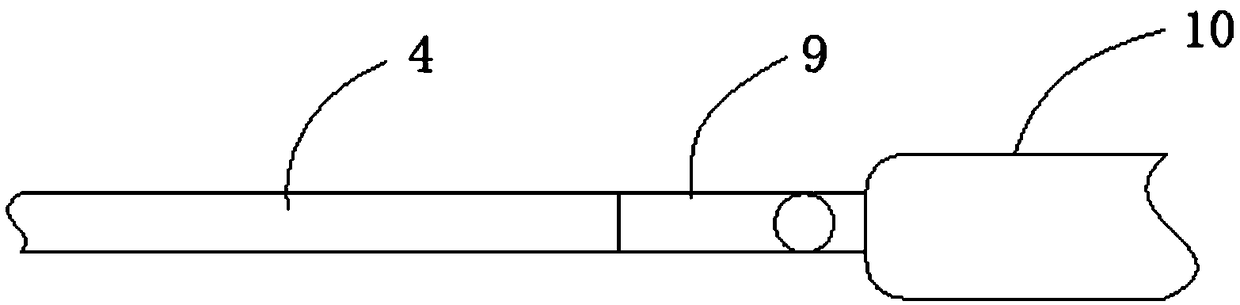

[0023] See figure 2 , the MI mineral insulated armored...

Embodiment 2

[0027] This embodiment is basically the same as the technical solution in Embodiment 1, the only difference is that in this embodiment, the support net 3 is a silicon crystal net, which does not rust, does not scratch the pipeline, has strong tensile strength, and is environmentally friendly .

Embodiment 3

[0029] The technical solution in this embodiment is basically the same as that in Embodiment 1, the only difference is that in this embodiment, a temperature controller is also provided, and the temperature controller is connected to the MI mineral insulated armored heating cable layer 4 .

[0030] The working principle of the present invention is as follows:

[0031] After the heating cable is energized and heated quickly, the heat is instantly transferred to the aluminum plate and the surrounding heat storage layer 2 (preferably the cement layer), and the surrounding heat storage layer 2 is transferred from the bottom by using the high heat transfer and thermal mirror reflection of the wire itself and the aluminum plate The cloth heats up evenly and quickly. The ground is covered with cement, and the heat quickly accumulates and is conducted to the surface. The heat cycle is carried out in the building space, so that the room can reach the preset temperature in a short time. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com