Reverberating furnace feeding device

A technology of feeding device and reverberatory furnace, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of high labor cost, inability to accurately quantitative feeding, poor production continuity, etc., and achieve low labor cost, Simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

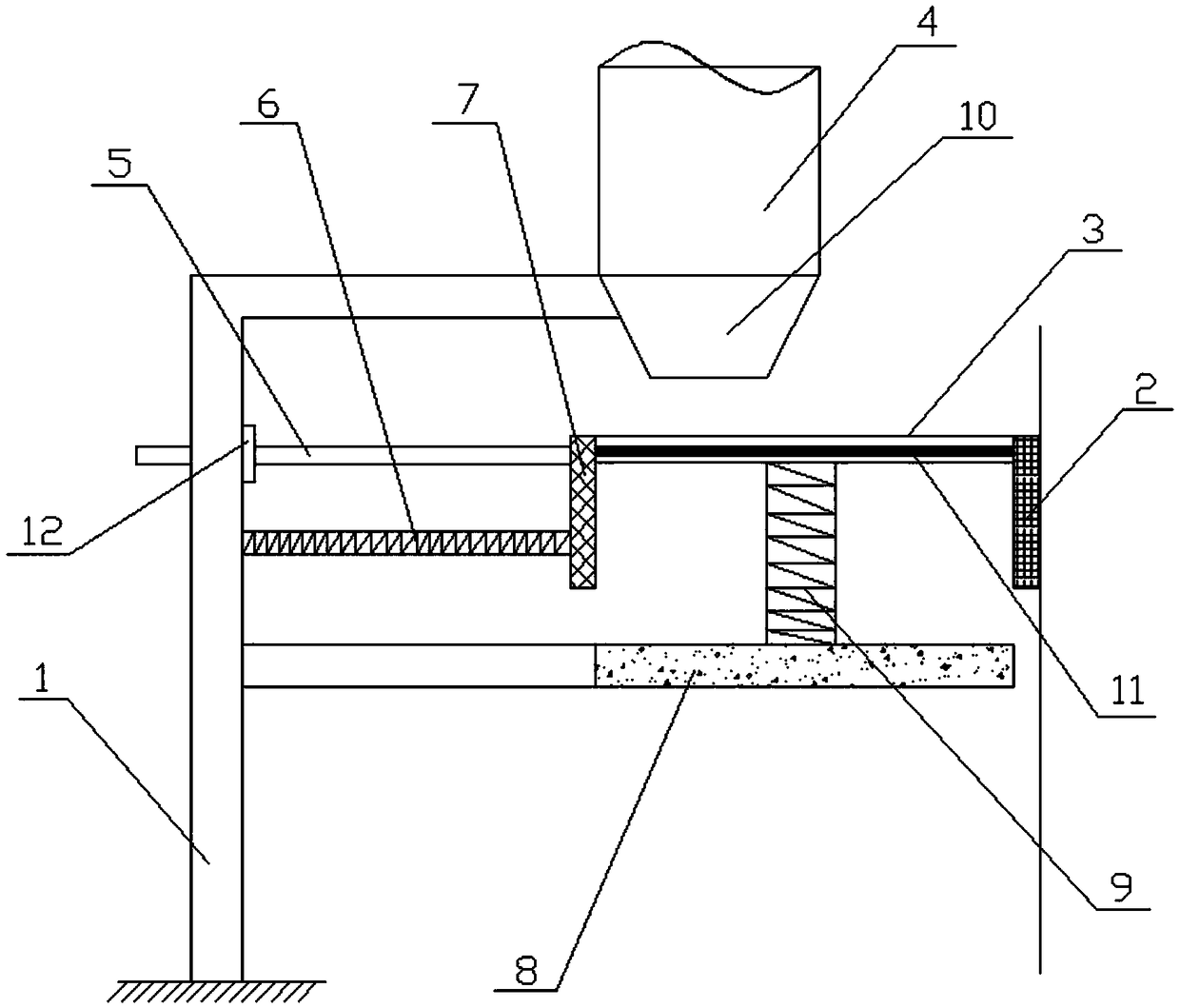

[0020] Such as figure 1 As shown, a reverberatory furnace feeding device includes a bracket, a feeding port cover, a material plate, a feed bin, a pull rod, a push spring, a push plate, an electromagnetic plate, a metering spring and a discharge port, and the feed bin is placed on the bracket The top, the bottom of the silo is provided with a discharge port, the feed port cover is installed at the feed port of the reverberatory furnace, the push plate and the feed port cover are respectively located at the two ends of the material plate, the material plate and the push plate It is not connected, it is connected with the feed port cover, the bottom is provided with a metering spring, the material plate is located below the discharge port, the bottom of the metering spring is connected to the electromagnetic plate, the electromagnetic plate is installed on the bracket, and the push plate is pushed through The material spring and the pull rod are connected with the support, an ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com