A Concrete Contact Dissolution Test Device Considering Splitting Stress

A technology for concrete specimens and tensile stress, which is applied in the direction of measuring devices, testing wear resistance, weather resistance/light resistance/corrosion resistance, etc., can solve problems such as stress relaxation, and achieve stress avoidance, consistency assurance, and accurate test data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

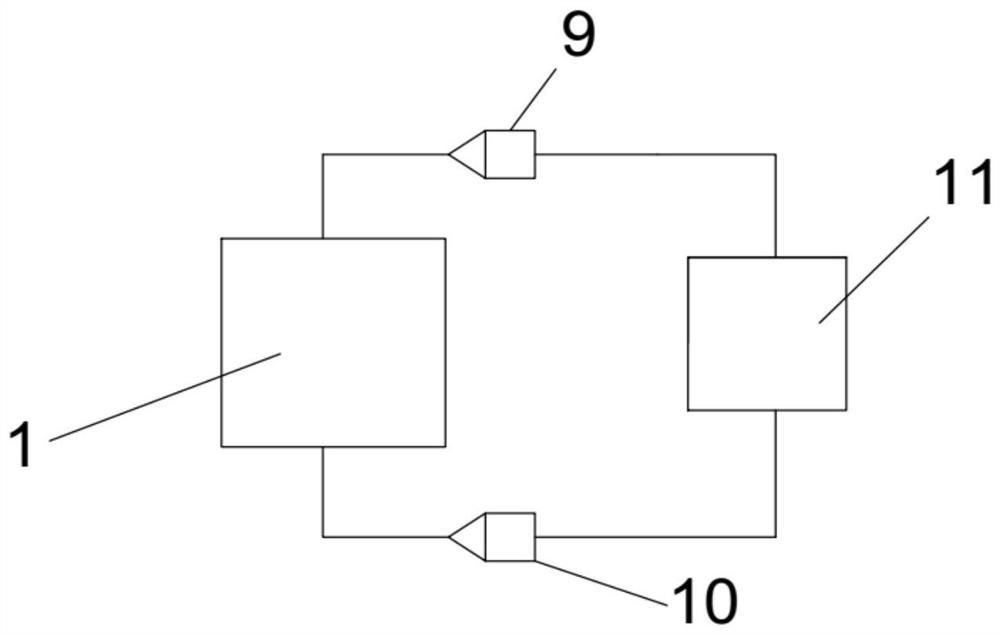

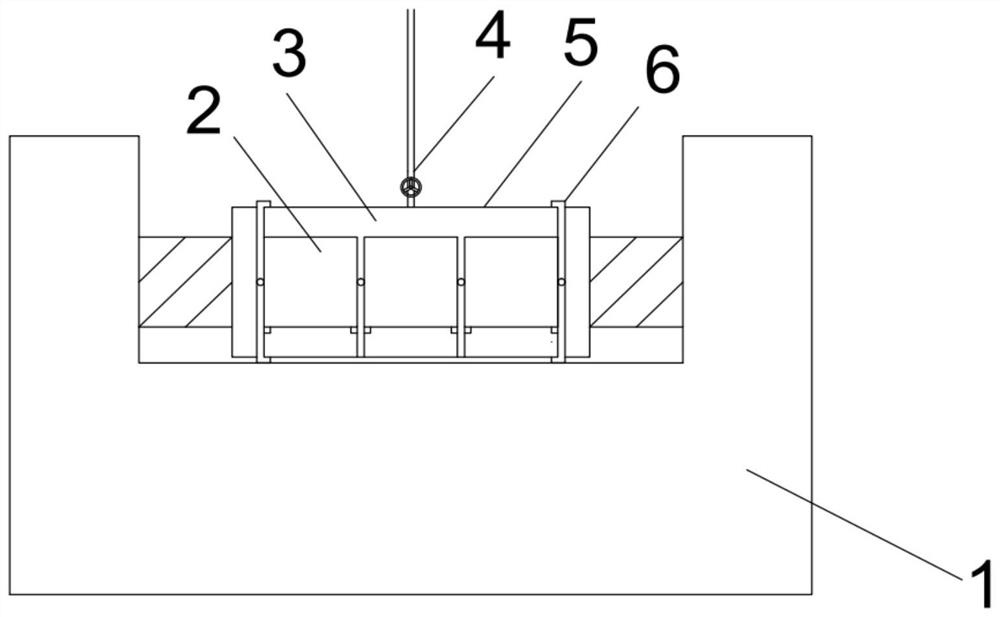

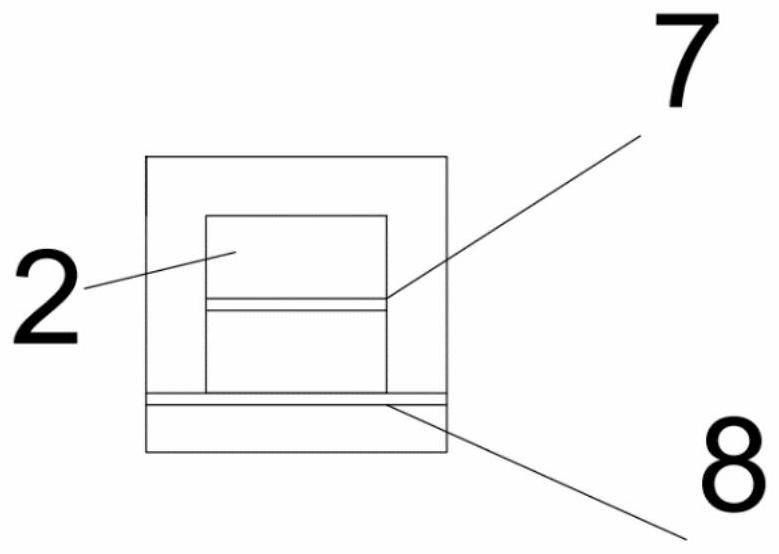

[0025] see figure 1 , a concrete contact corrosion test device considering splitting stress, including a stress loading device 1, a hydraulic sensor 9, a salt solution concentration sensor 10 and a computer terminal 11.

[0026] Stress loading device 1 is a lateral loading testing machine, which loads 3 specimens laterally at a time to ensure that a group of specimens bears the same force. At the same time, compared with the vertical loading of traditional universal testing machines, lateral loading can avoid the gravity of the upper concrete specimen 2. The stress caused to the lower test piece makes the stress control more accurate. The hydraulic sensor 9 is placed inside the stress loading device and establishes real-time signal transmission with the computer terminal, which can display and control the applied load in real time and convert i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com