Fishbone-shaped winding type gasket

A winding, fishbone-shaped technology, applied in the direction of engine sealing, flange connection, pipe/pipe joint/pipe fittings, etc., can solve the problems of plane accuracy drop, seal failure, etc., to achieve uniform force, high reliability, The effect of flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

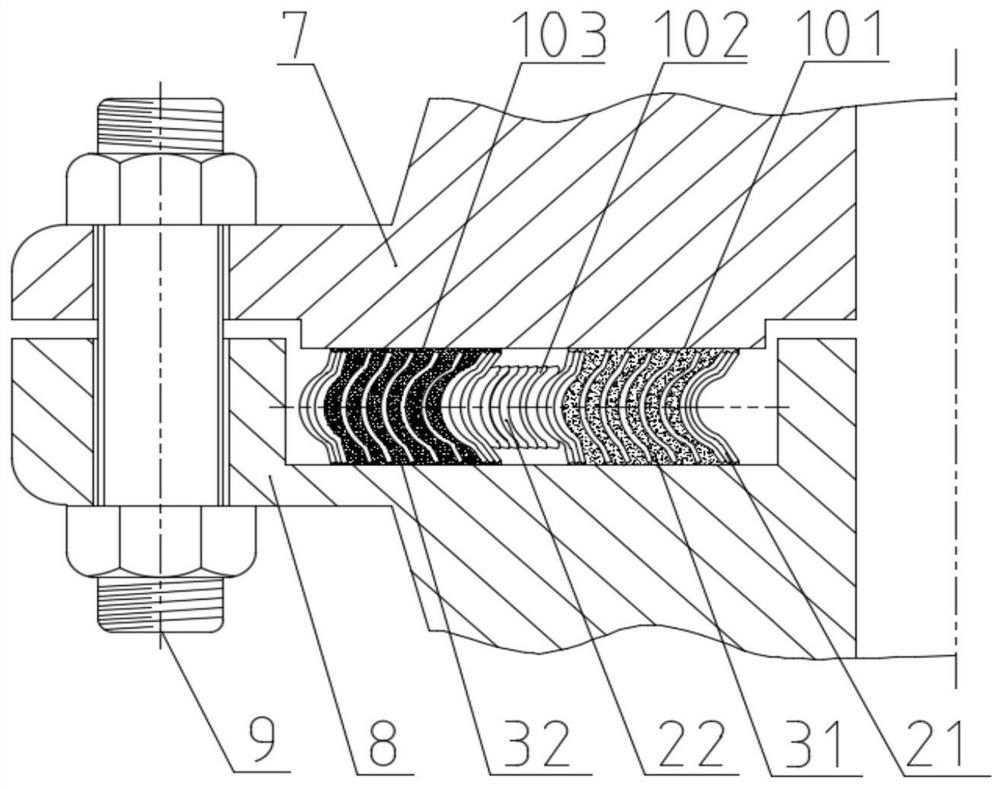

Embodiment 1

[0031] see figure 1 , where the gasket winding body 1 is installed on the tongue-and-groove flange surface for sealing, wherein the radial width of the winding part located in the middle of the gasket winding body 1 is lower than the radial width of the winding parts on both sides, providing the winding parts on both sides It provides a deformable space, improves the sealing performance when the gasket is wound around the main body 1, and at the same time plays a secondary support effect on the flange connection surface. A plurality of CV-shaped wide-section steel strips 21 are tightly wound into a ring along the circumferential direction. The first winding part 101 and the third winding part 103 are respectively formed. A plurality of CV-shaped narrow-section steel strips 22 are tightly wound in a ring shape along the circumferential direction to form the second winding part 102. The winding parts are arranged concentrically, and the second The wrapping part 102 is located on...

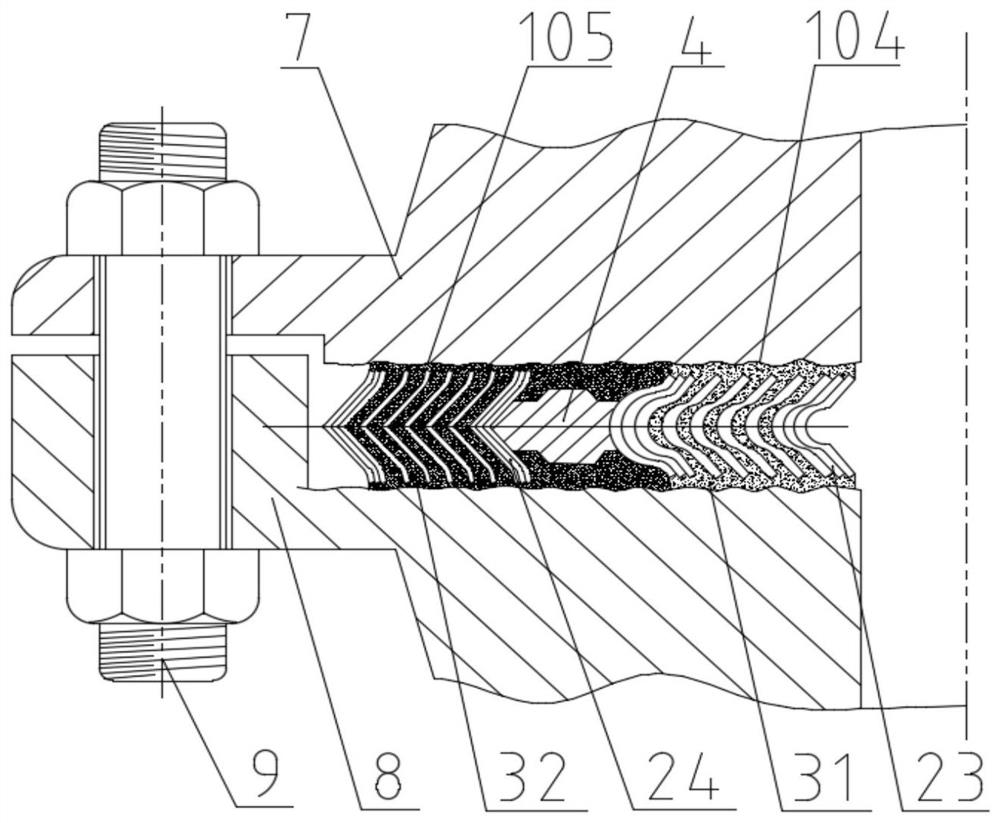

Embodiment 2

[0033] see figure 2, where the gasket winding body 1 is installed on the rough surface of the concave-convex flange for sealing, the connection surface between the upper flange 7 and the lower flange 8 is uneven and rough, and the radial width of the non-metallic sealing material 3 is larger than the steel strip The radial width of 2, the non-metallic sealing material 3 located on the upper and lower sides of the gasket winding body 1 can produce a certain degree of deformation according to the rough surface of the concave-convex flange to fill the gap, thereby improving the sealing of the connecting surface, and the gasket winding The body 1 has a built-in anti-pressure ring 4 coaxial with the annular central axis of the gasket winding body 1, and the inner diameter and outer diameter of the anti-pressure ring 4 are respectively matched with the corresponding connected winding parts in the circumferential direction to prevent the sealing interface from being over-pressured an...

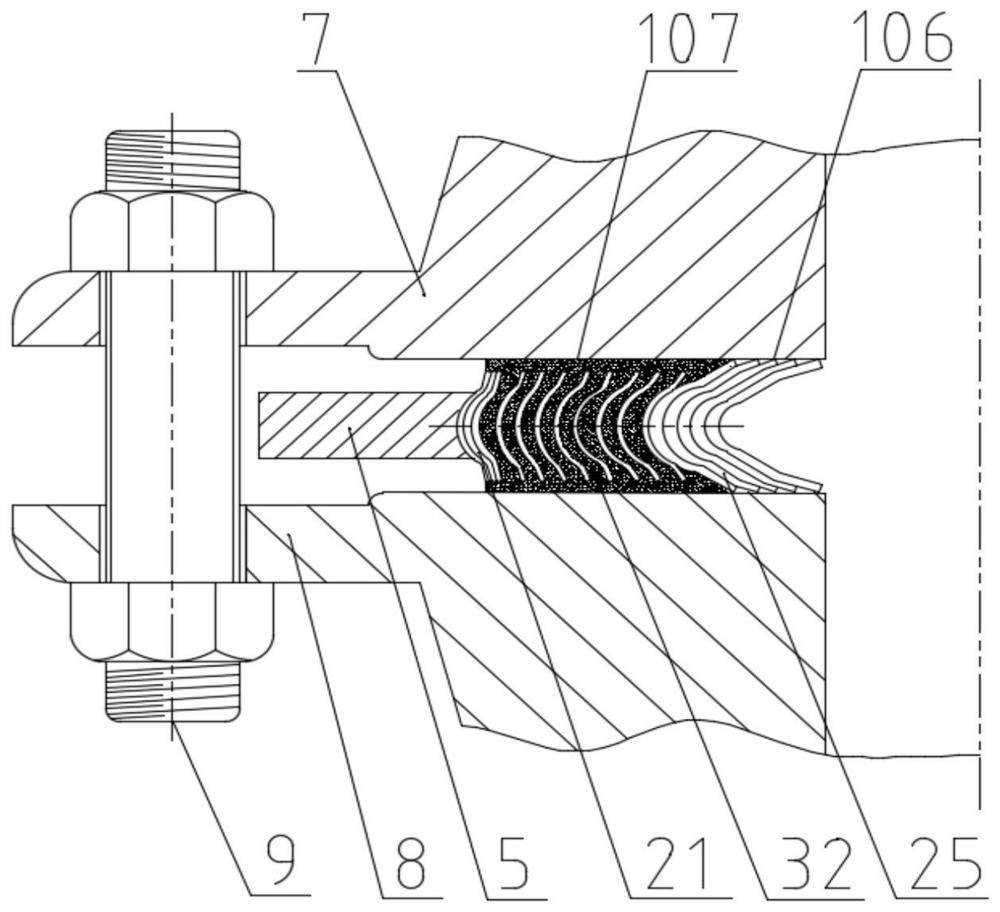

Embodiment 3

[0035] see image 3 , here the gasket winding body 1 is installed on the connection plane flange surface for sealing, and the outer reinforcement ring 5 connected to the outer side of the winding ring plays a supporting role. To the sixth winding part 106 tightly wound into a ring shape, a plurality of CV-shaped wide-section steel strips 21 tightly wound into a ring shape in the circumferential direction to form a seventh winding part 107 and the outer reinforcing ring 5, between the winding parts They are arranged concentrically, wherein the outer reinforcement ring 5 is located on the side of the seventh winding portion 107 close to the fastening bolt 9 , and the sixth winding portion 106 is located on the side of the seventh winding portion 107 away from the fastening bolt 9 . The high-temperature sealing material 32 is arranged in the gap between two adjacent CV-shaped wide-section steel strips 21 on the seventh winding portion 107, and the radial width of the high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com