Electric-heating film greenhouse

A technology of greenhouse and electric heating film, applied in the field of greenhouse, can solve the problems of electric leakage safety accident and high energy consumption, and achieve the effect of improving ground temperature, high thermal efficiency and simple technical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

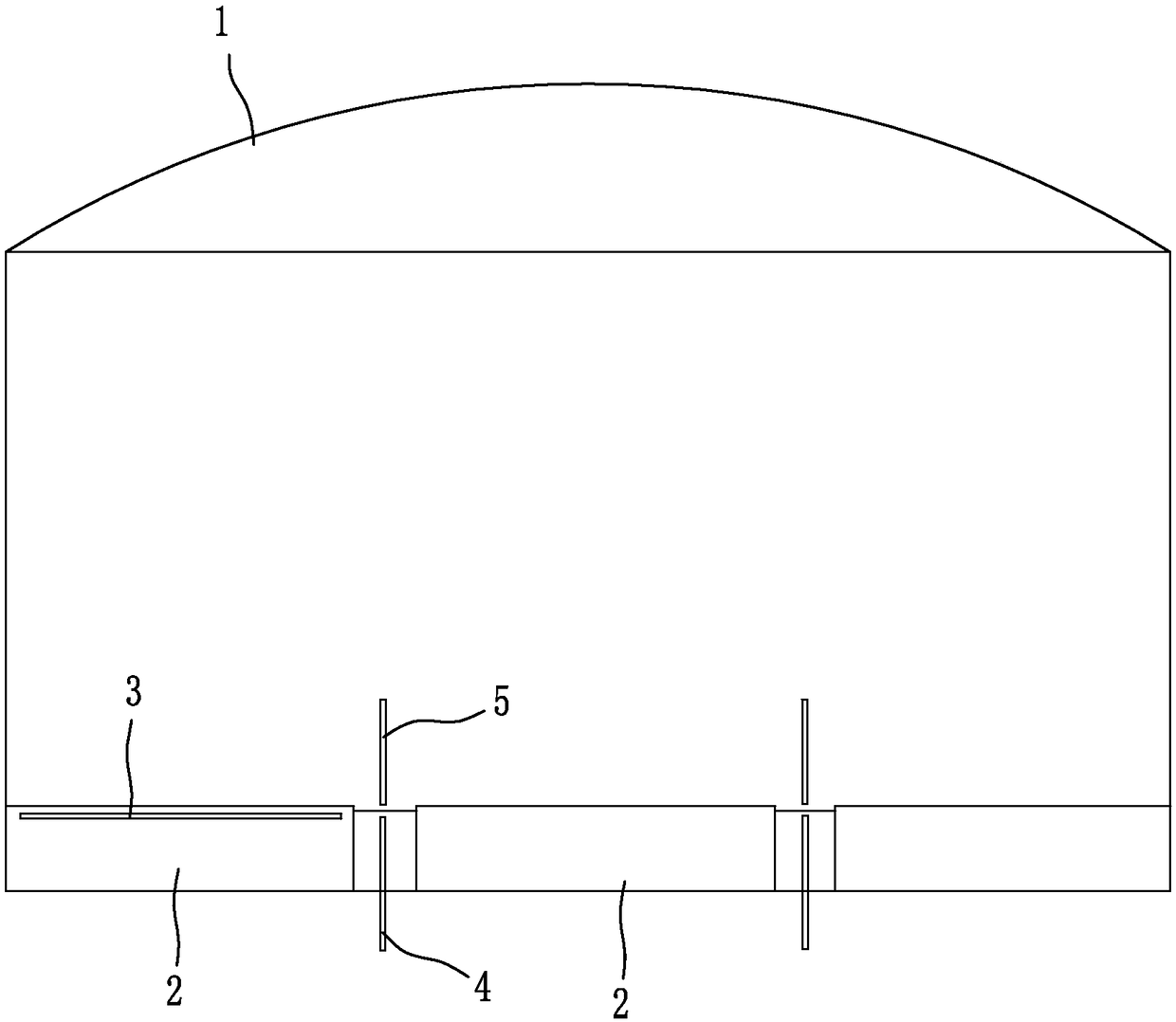

[0011] Such as figure 1 As shown, an electric heating film greenhouse includes a greenhouse 1, and the bottom of the cultivation furrow 2 in the greenhouse 1 of the present invention is tiled with an electric heating film 3 facing upward and / or the bottom between the cultivation furrows 2 is vertical. The electrothermal film 4 of double-sided heating is laid.

[0012] Tiled electrothermal film 3, for those who adopt plug trays or nutrient bowls to grow seedlings, the electric heating film 3 is tiled on the cultivation bed 2 with the heating side facing up, and the electric heating film 3 is covered with fine soil. The thickness of the fine soil cover is about 2cm, and then Place the plug tray or nutrient bowl in the covered fine soil. If the seedbed is used to grow seedlings, the laying depth of the electrothermal film 3 in the cultivation furrow 2 is about 5 cm, and the film is covered with nutrient soil.

[0013] For the vertically laid electric heating film 4, the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com