Bag dust removal system for hazardous waste industry

A bag dust removal and industrial technology, applied in the field of bag dust removal system in hazardous waste industry, can solve the problems of filter bag material not meeting the media requirements, incomplete pulse cleaning, poor top insulation effect, etc., to avoid rapid temperature drop and good dust removal. effect, the effect of avoiding air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following embodiments are used to illustrate the present invention, but not to limit the scope of the present invention.

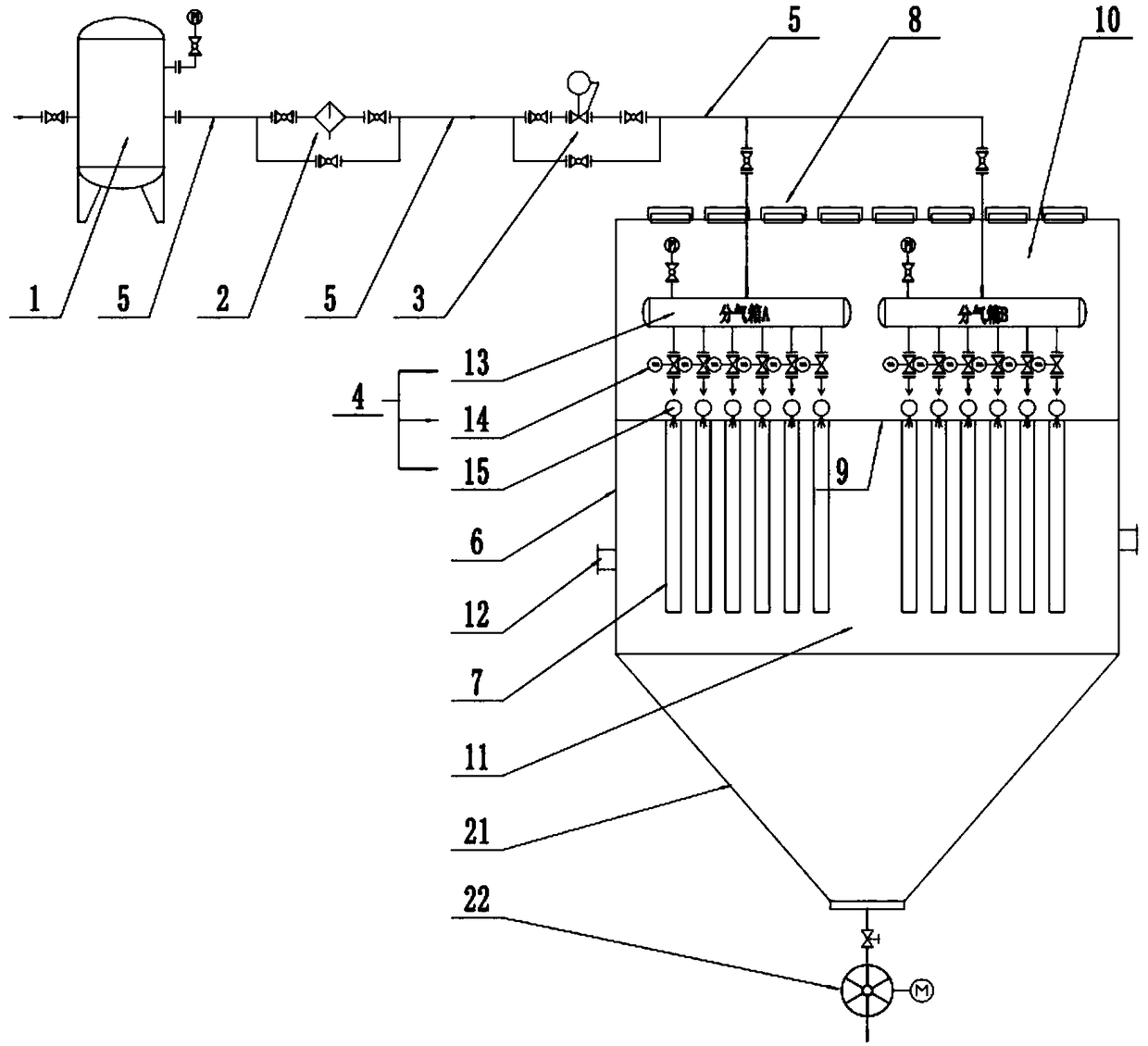

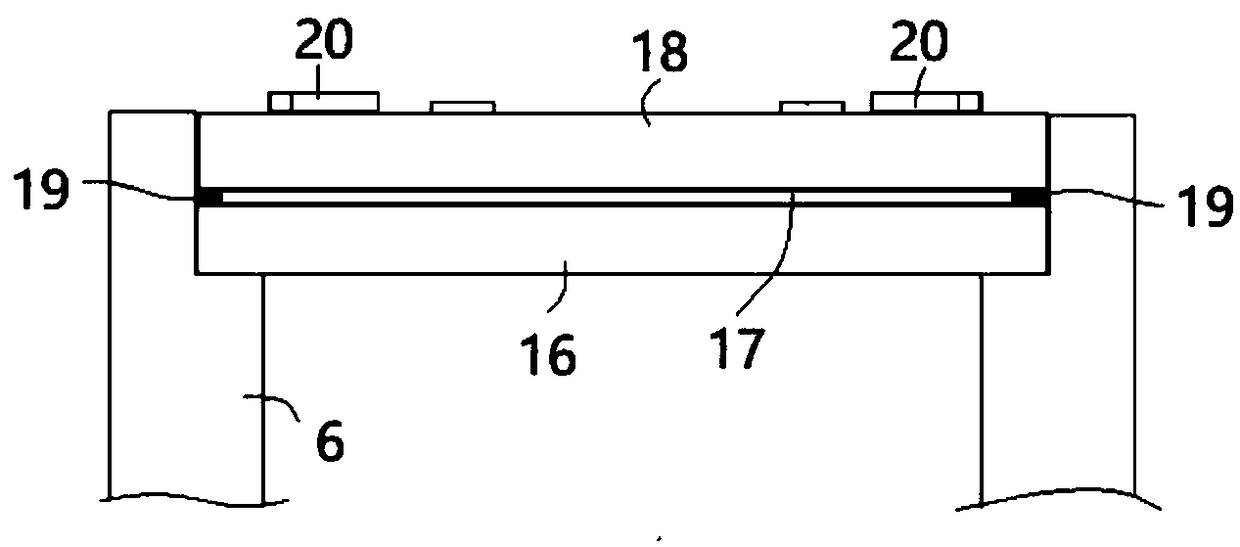

[0019] Such as figure 1 and 2 As shown, the embodiment provides a bag dust removal system for hazardous waste industry, which includes a compressed air storage tank 1, an air filter 2, a pressure regulator 3, a pulse cleaning device 4, a gas pipeline 5, a housing 6, and a filter bag 7 and a double-cover insulation device 8, the gas pipeline 5 is sequentially connected to the compressed air storage tank 1, the air filter 2 and the pressure regulating device 3, and a flower plate 9 is arranged inside the housing 6, and the flower plate 9 connects the housing 6 The inner space is divided into a clean air chamber 10 and a dust-containing air chamber 11 distributed up and down. The clean air chamber 10 is provided with an exhaust pipe (not shown in the figure), the dust-containing air chamber 11 is provided with an air intake pipe 12, and the flower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com