Beaver incisor structure-imitated anti-corrosion branch crushing tool

A branch crushing and corrosion-resistant technology, which is applied in grain processing and other directions, can solve the problems of large cutting resistance, easy corrosion, and high power consumption of the grinder cutter, and achieve the goals of improving cutting and crushing efficiency, improving corrosion resistance, and preventing breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] In order to further illustrate the technical solutions of the present invention, in conjunction with the accompanying drawings, the specific embodiments of the present invention are as follows:

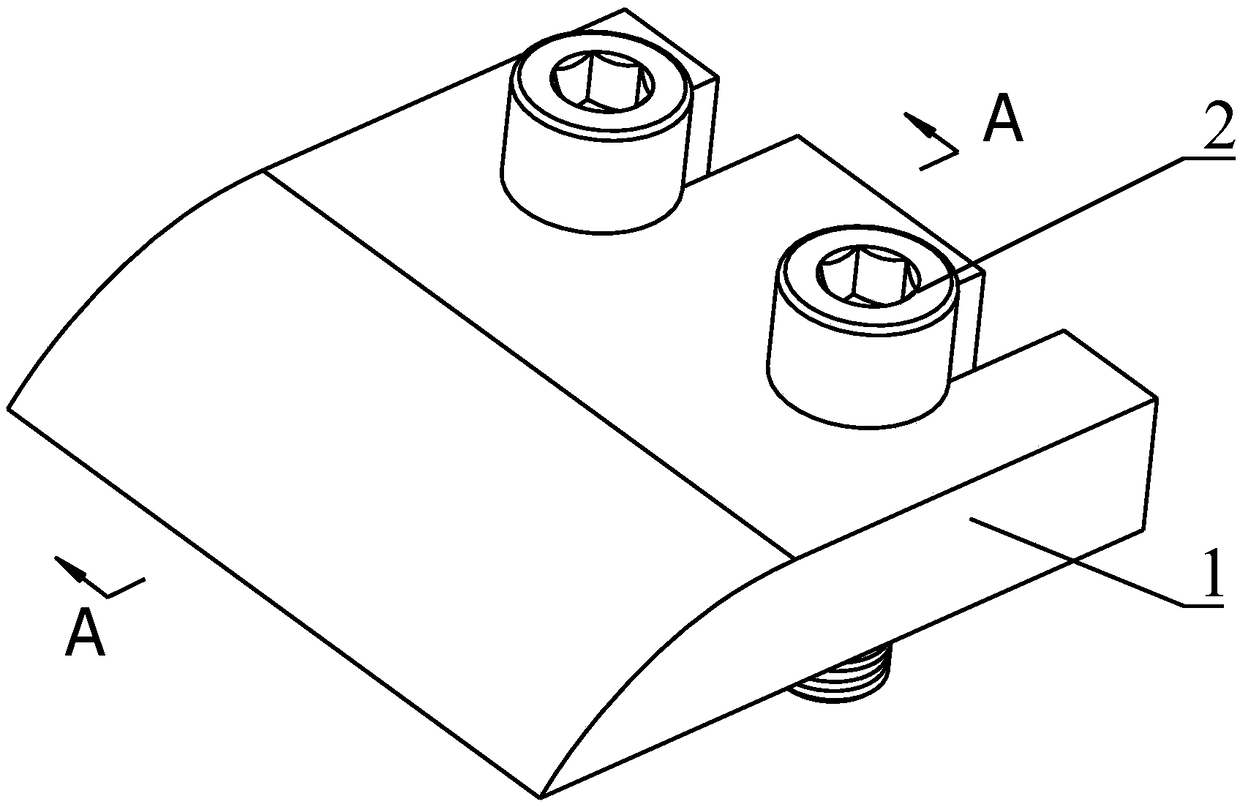

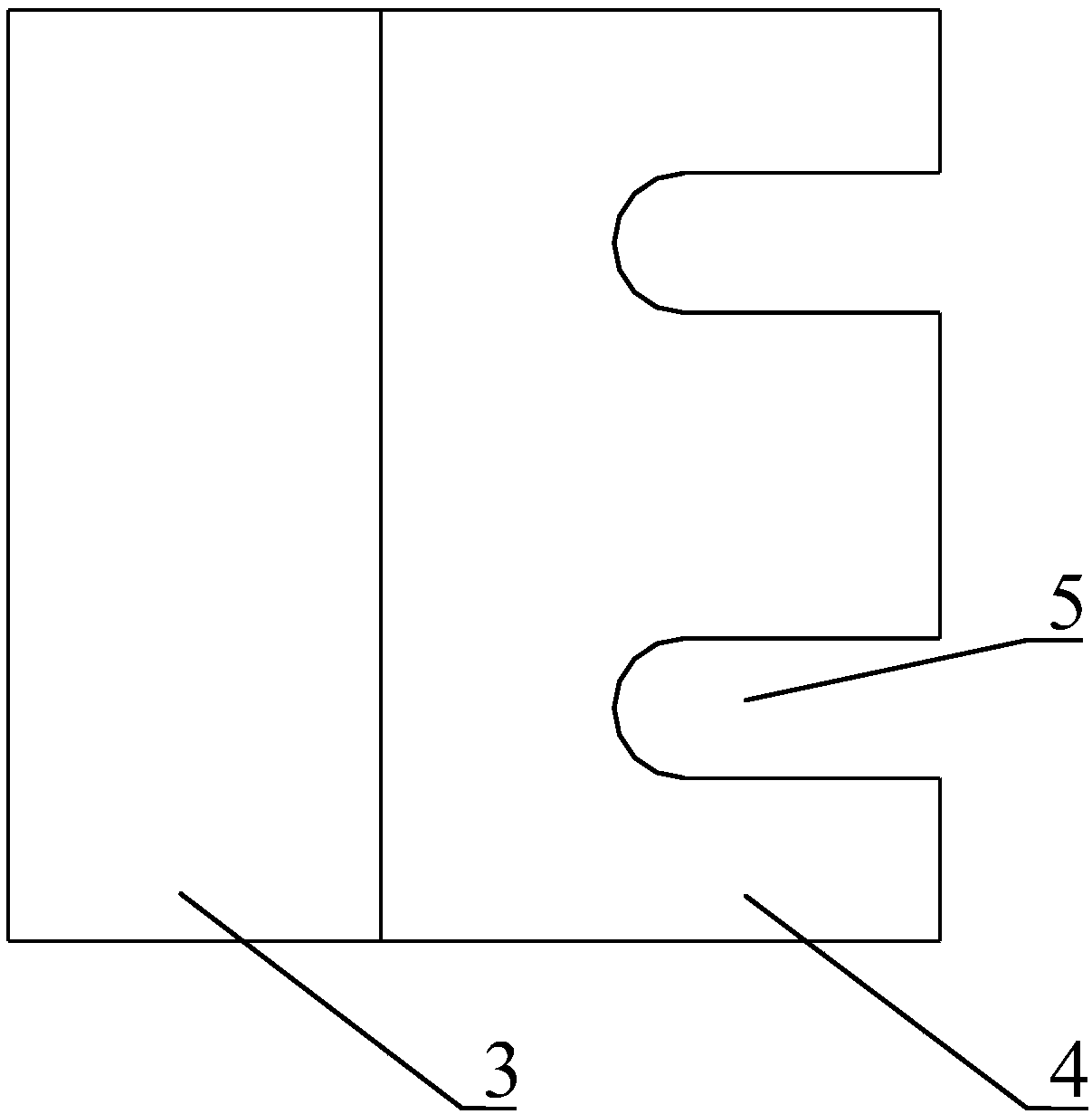

[0026] like figure 1 and image 3 As shown in the figure, the present invention provides a bionic branch smashing tool based on a beaver incisor structure. 3 and the shank 4 at the rear end of the integrated structure, the rear end of the shank 4 is symmetrically opened with two U-shaped positioning holes 5 with horizontal openings facing backward, and the positioning bolts 2 have two groups, which are respectively perpendicular to the The handle 4 is installed in the U-shaped positioning hole 5, so as to realize the fixed assembly connection between the bionic blade 1 and the body (not shown in the figure) of the shredder.

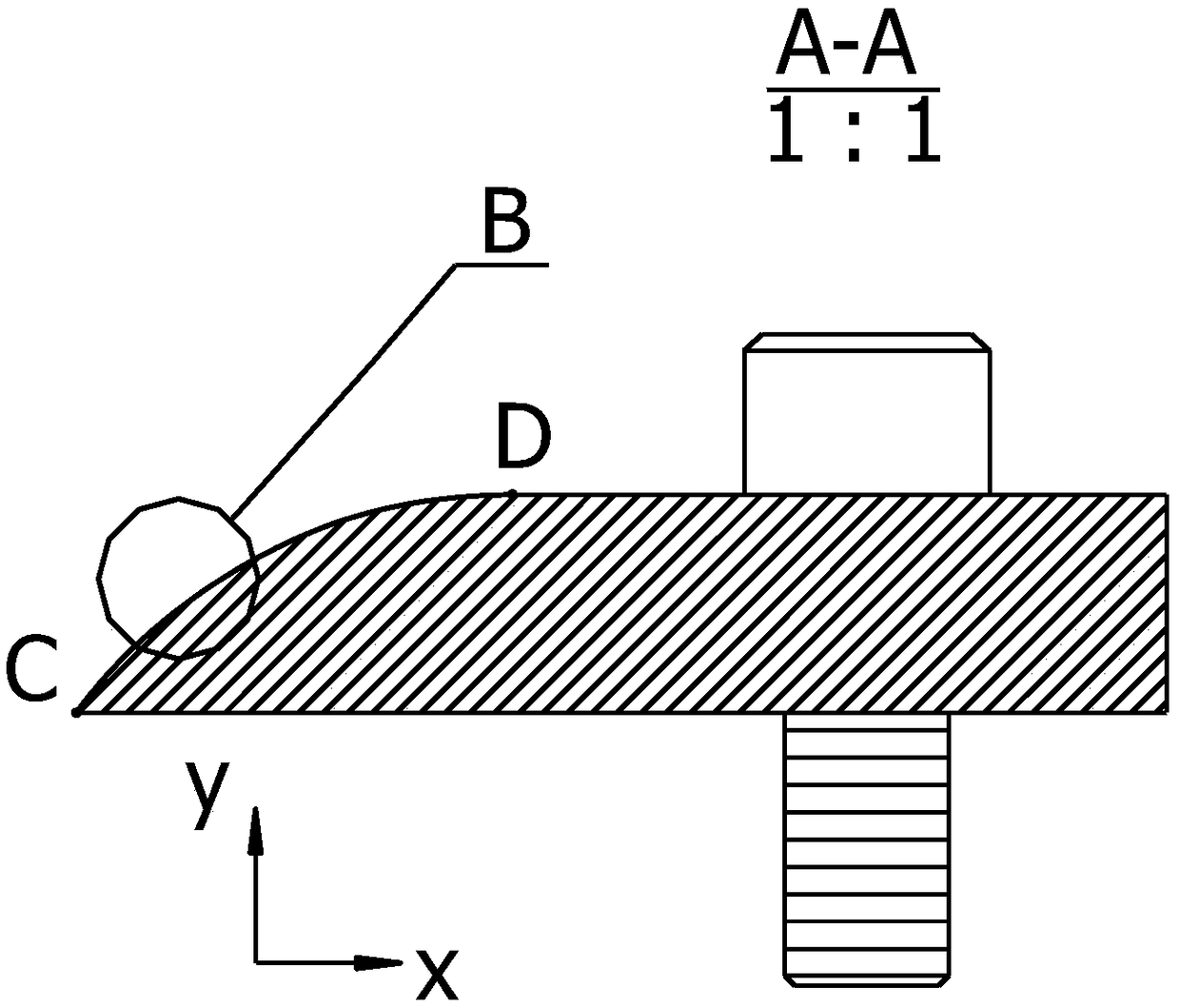

[0027] like figure 2 As shown, the contour curve CD of the upper cutting surface of the bionic cutting edge 3 of the bionic blade 1 is to imitate the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com