Numerically controlled bending automatic matching method and system

An automatic matching and database technology, applied in the direction of comprehensive factory control, can solve problems such as high requirements and parts processing errors, and achieve the effect of improving production efficiency, improving work efficiency and reducing dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

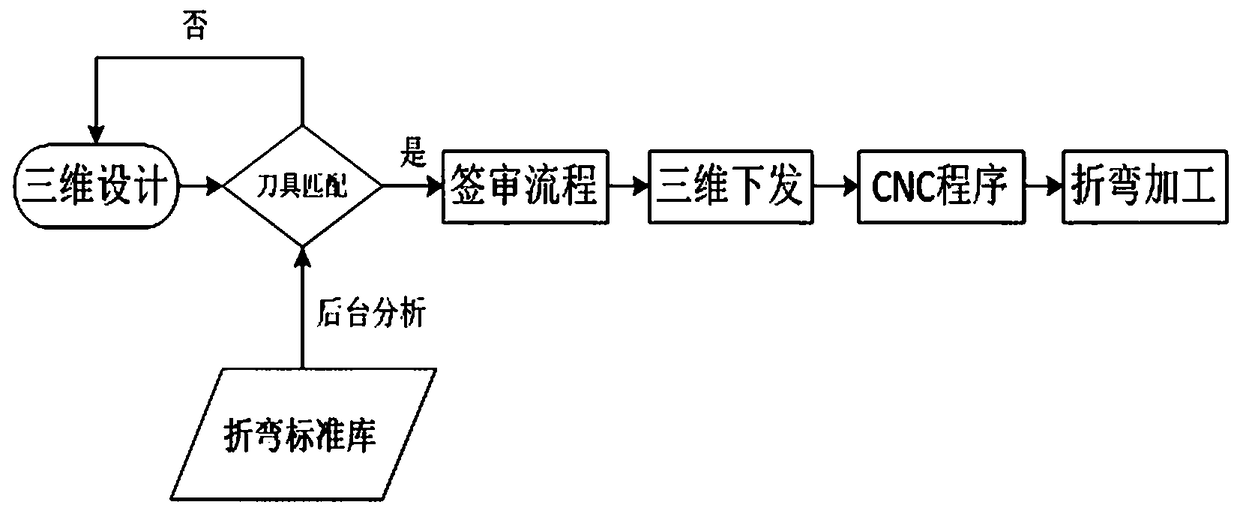

[0026] Such as figure 2 As shown, the numerical control bending automatic matching method proposed by the present invention is mainly used for the bending processing of sheet metal parts, and the method includes steps 1 to 3, which will be described respectively below.

[0027] Step 1. Create a bending standard library and embed it into the 3D design platform in a parametric form. Bending equipment library, tool library, upper and lower die position library, and bending rule library. The bending equipment library contains several CNC bending machines and the corresponding processing rules of each CNC bending machine. The processing rules include the programming of the CNC bending machine rule. The bending rule library includes: tool combination rules, sorting rules, yield rules, sheet metal material thickness matching rules, bending compensation coefficient table and bending expansion coefficient table. The bending compensation coefficient table should contain different bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com