Tempering technology of G18CrMo2-6 steel

A technology of process and process parameters, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve the problems of carbide particle growth and uneven performance, and achieve fine carbides, scientific design results, and good impact toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this example, the G18CrMo2-6 steel material is G18CrMo2-6, and its chemical composition is shown in Table 1:

[0030] Table 1, chemical composition of nuclear power high pressure cylinder G18CrMo2-6 (mass fraction, %)

[0031] the element

C

Si

mn

P

S

Cu

Composition specification

0.15~0.20

0.20~0.60

0.50~0.90

≤0.025

≤0.025

≤0.50

the element

Cr

Mo

Ni

V

Fe

-

Composition specification

0.40~0.65

0.45~0.70

0.30~0.50

≤0.04

bal.

-

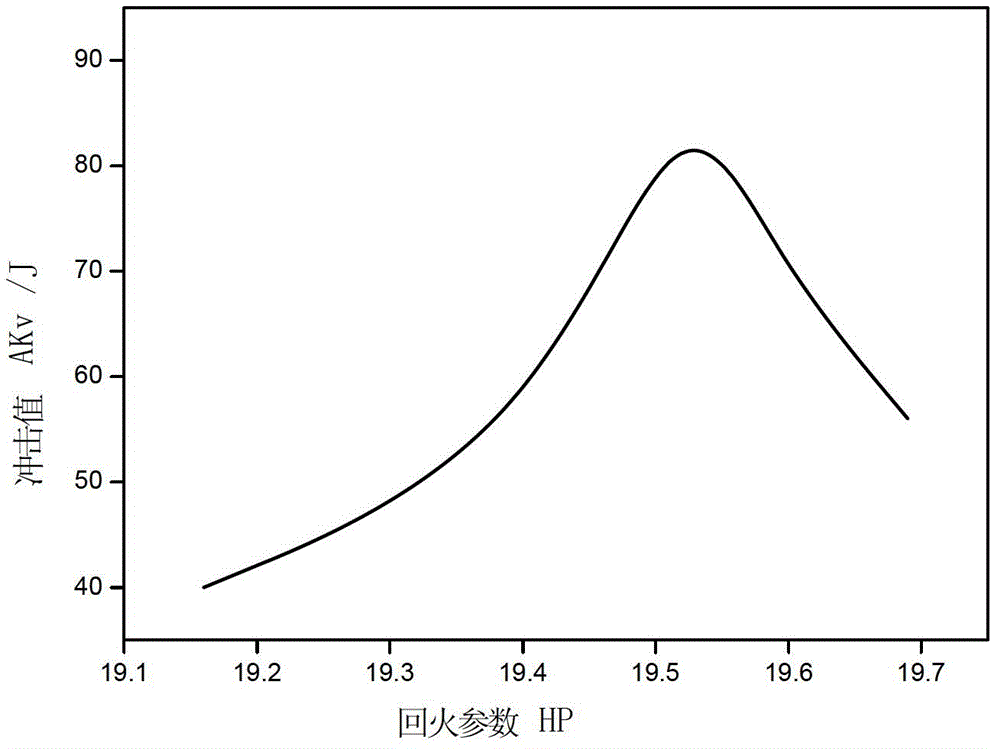

[0032] 1) Heat the G18CrMo2-6 steel G18CrMo2-6 that has been subjected to normalizing heat treatment to 660°C at a heating rate of 50°C / h for heat preservation for 2h, 4h, 6h, 8h, and 10h, and temper at a certain cooling rate of 50°C / h to cool to room temperature. The Charpy V-port room temperature impact test was carried out, and the test data obtained are shown in Table 2:

[0033] Table 2. Impact test data of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com