Quick positioning cutting device for automobile data recorder processing

A driving recorder and cutting device technology, applied in the field of cutting devices, can solve problems such as affecting production efficiency, wasting resources, wasting human resources, etc., and achieving the effects of facilitating work tools and testing tools, avoiding safety accidents, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

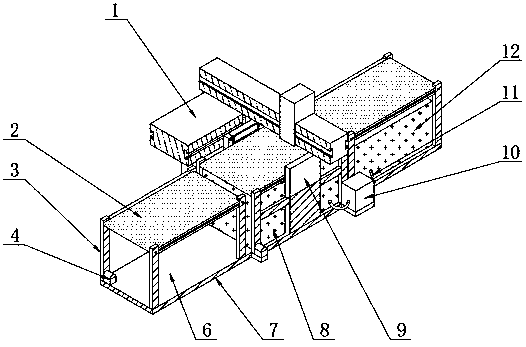

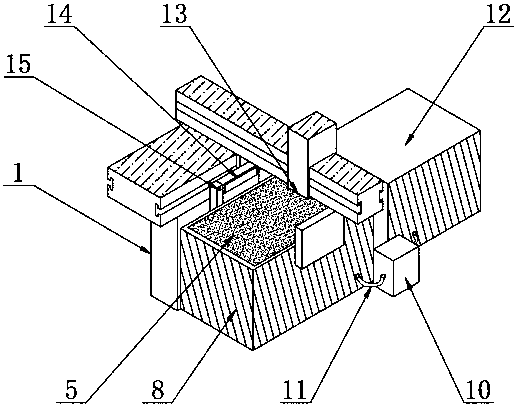

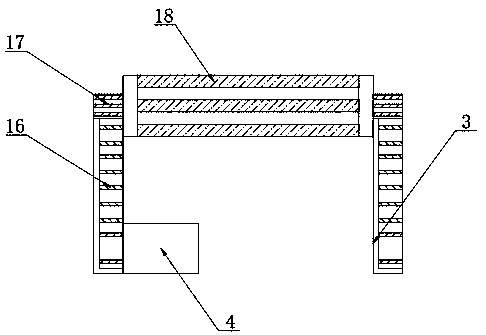

[0023] see Figure 1~4 , in an embodiment of the present invention, a cutting device that can be quickly positioned for processing a driving recorder includes a water cutter 1, a water tank 8 is installed under the front end of the water cutter 1, and a high-pressure water tank 12 is arranged on the right side of the water tank 8. And the left side of water tank 8 is provided with storage board 6, and water tank 8, storage board 6 and high-pressure water tank 12 are all installed on the base 7, and the top of water tank 8 and high-pressure water tank 12 is respectively provided with conveyor belt 2, and the upper end surface of base 7 is welded Conveyor belt bracket 3 is arranged, conveyor belt 2 and base 7 are connected to each other through conveyor belt bracket 3, positioning device 9 is arranged at the front and rear ends of water tank 8, water pump 10 is installed under the front end of water tank 8, water tank 8, high pressure water tank 12 and water pump 10 A plastic tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com