Bearing ring processing device

A technology of processing device and bearing ring, applied in the field of bearing ring processing, can solve problems such as troublesome operation and low efficiency, and achieve the effect of high processing efficiency, guaranteeing continuity and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

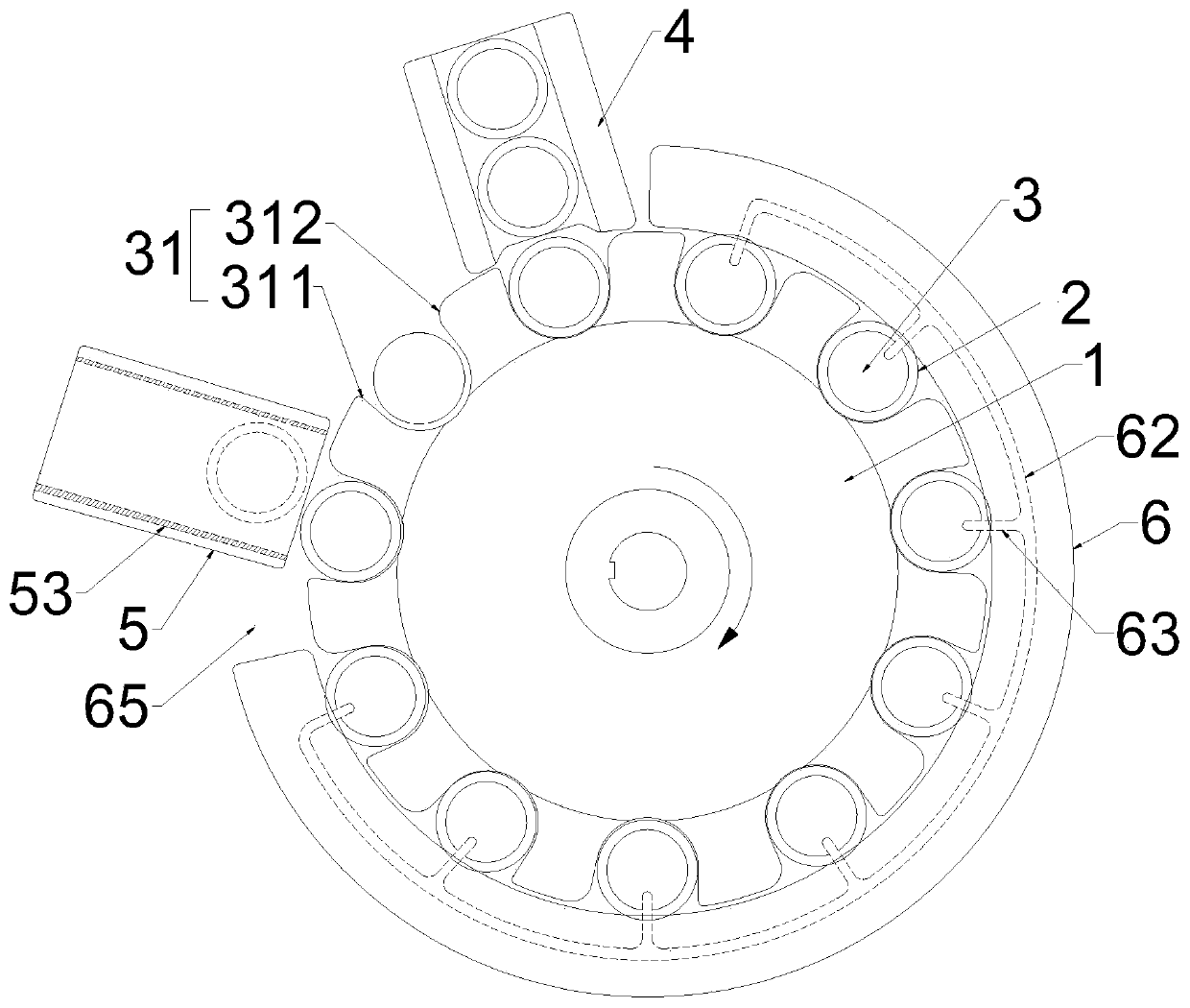

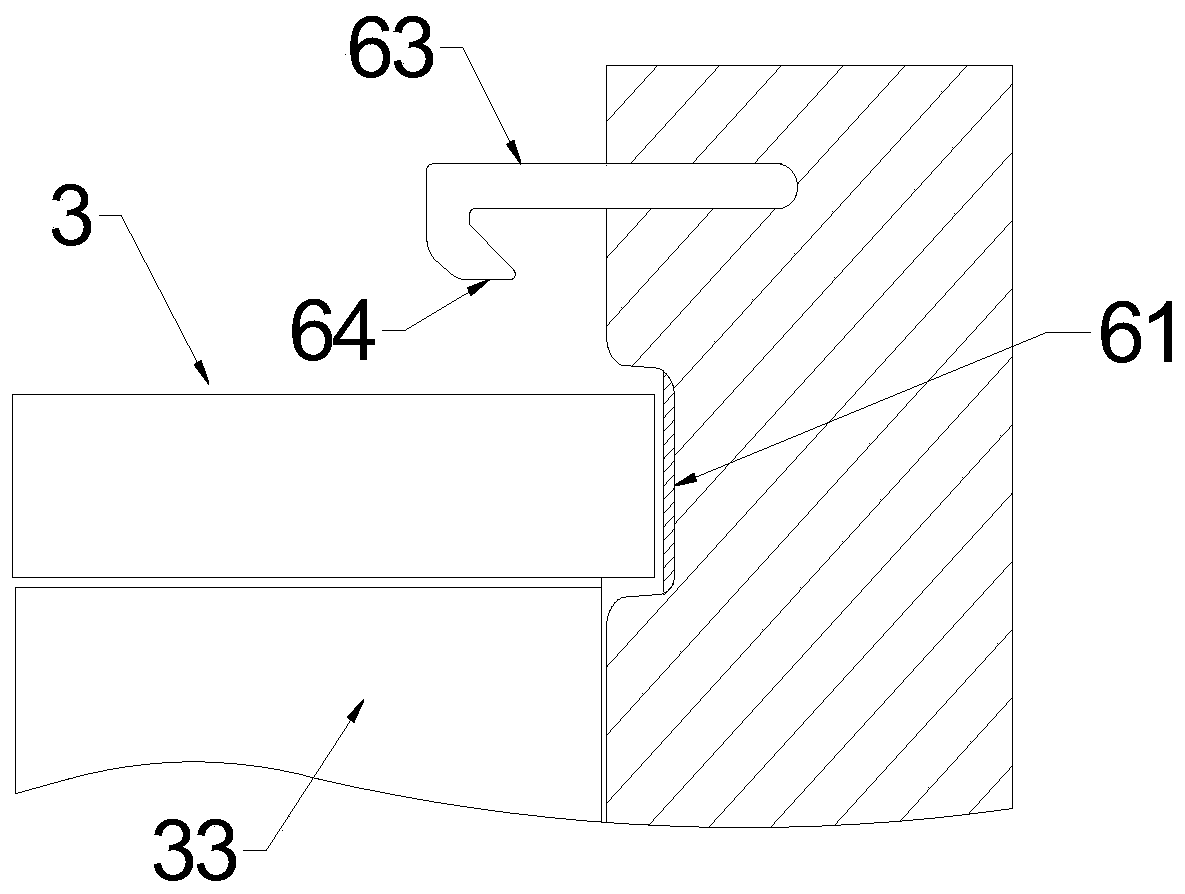

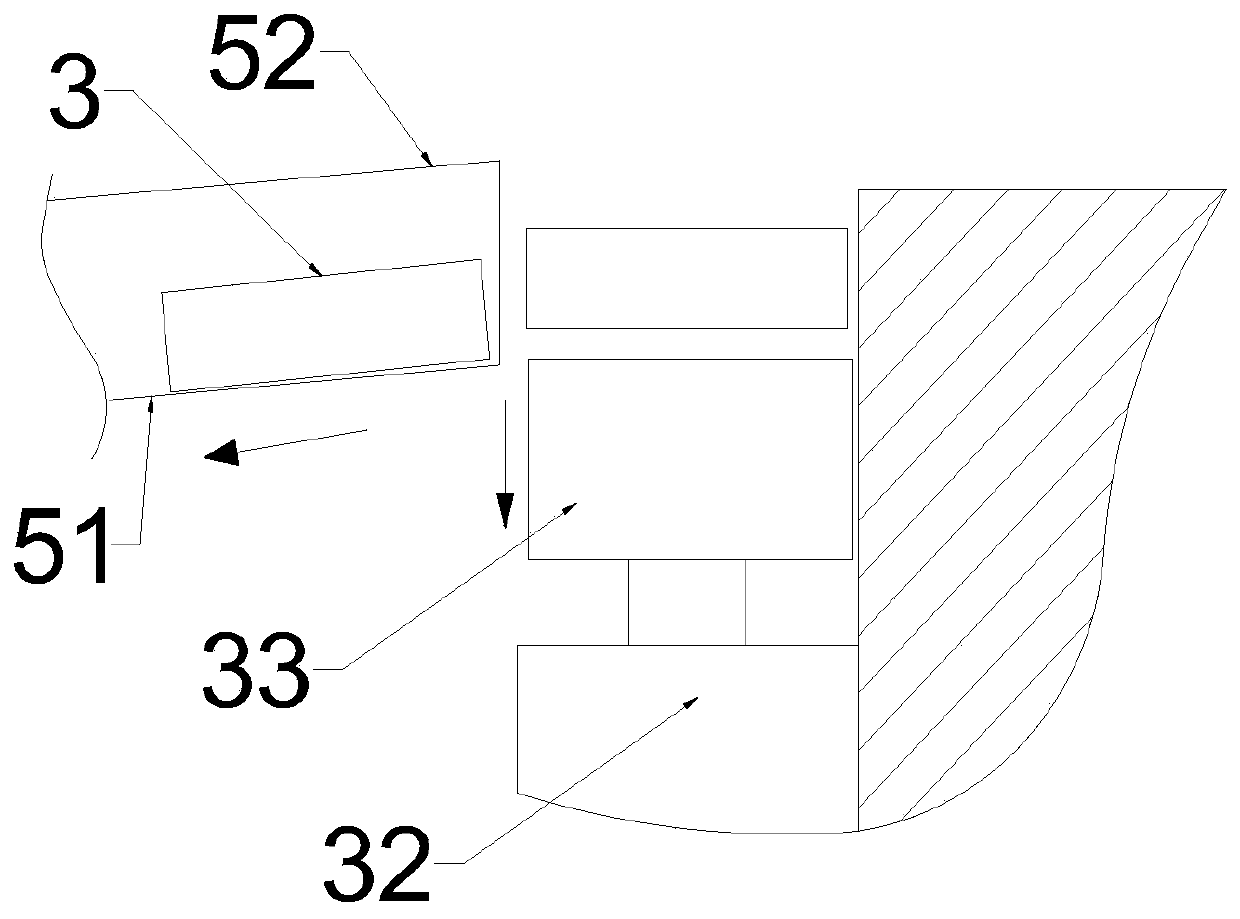

[0026] like figure 1 As shown, a bearing ring processing device includes a processing disc 1, a driving motor is connected to the bottom of the processing disc 1, and the driving motor can drive the processing disc to rotate. Above the processing disc 1, there are multiple The processing station 3 of the bearing ring 2, a plurality of processing stations 3 are evenly distributed on the outer circumference of the processing disc 1, and the outer side of the processing station 3 is provided with an open end 31 for feeding; the outer side of the processing disc 1 The feeding conveyor belt 4 and the unloading conveyor belt 5 are respectively arranged, and the feeding conveyor belt 4 and the unloading conveyor belt 5 are respectively located at the opening ends 31 of the two processing stations; the outer side of the processing disc 1 is provided with an annular grinder 6. The circumferential direction of the grinding machine 6 is provided with a gap 65 for avoiding the feeding con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com