Paper plate forming machine

A technology of forming machine and paper plate, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as cardboard damage, reduce the probability of damage, have a simple structure, and increase the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

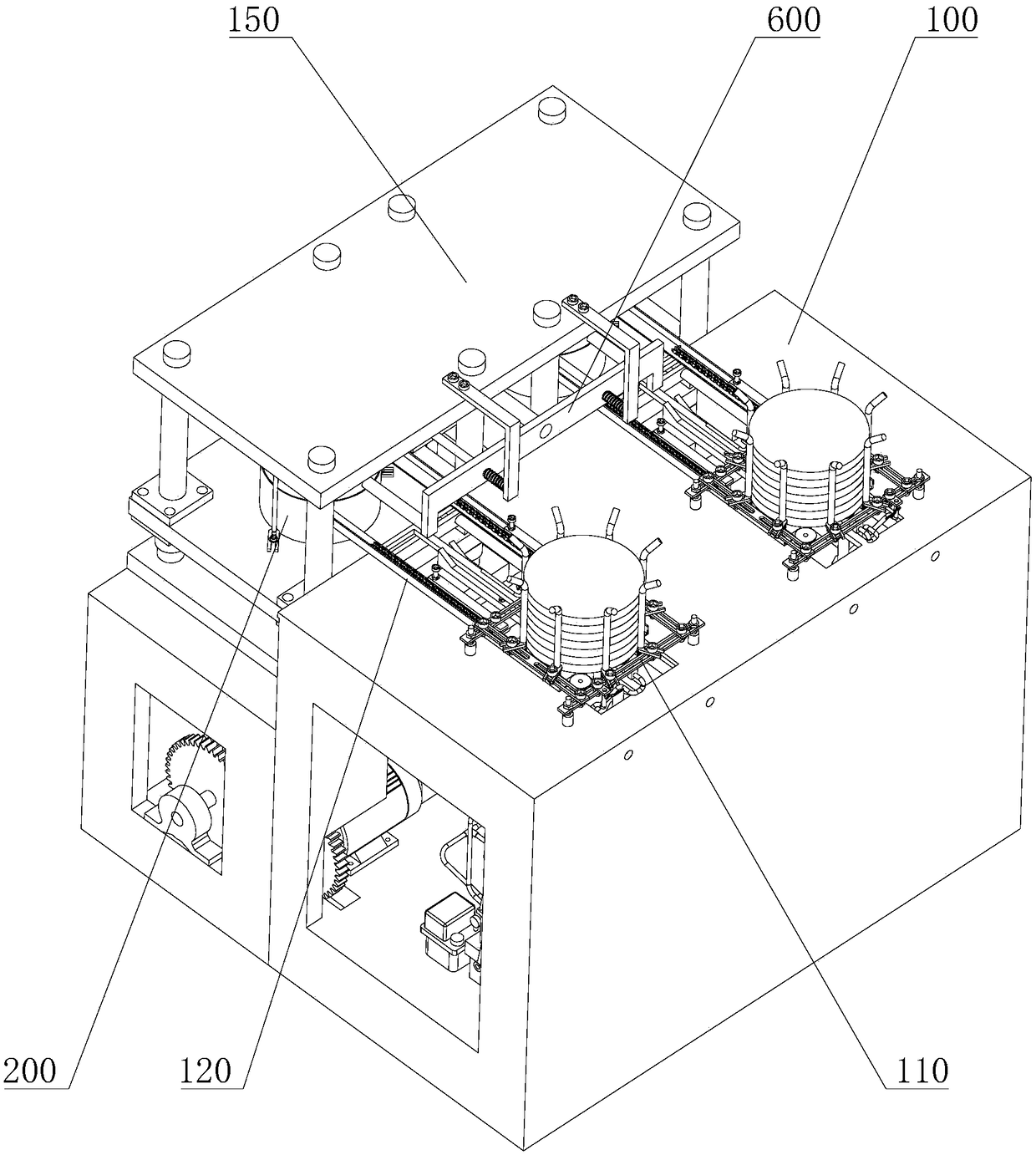

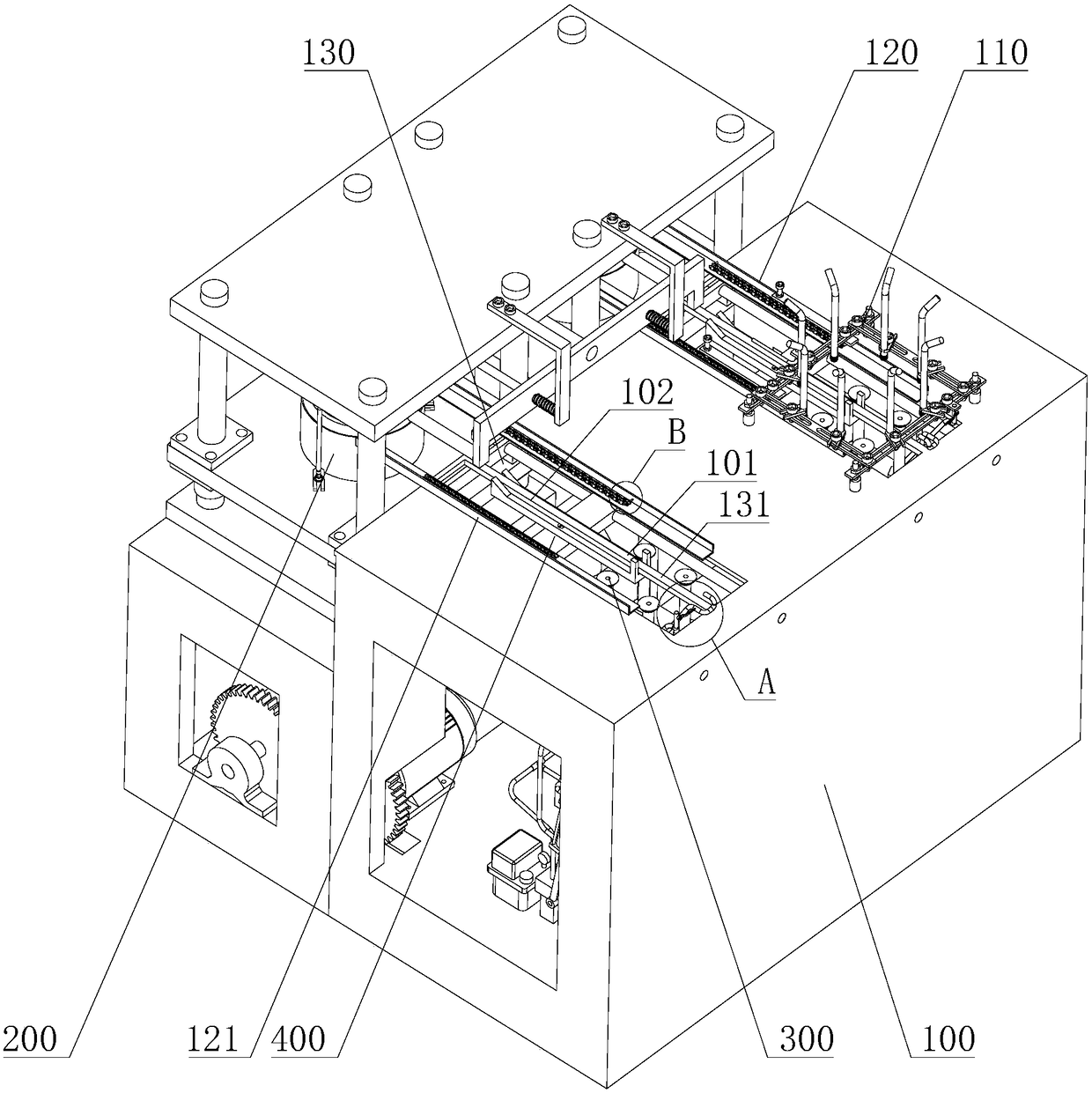

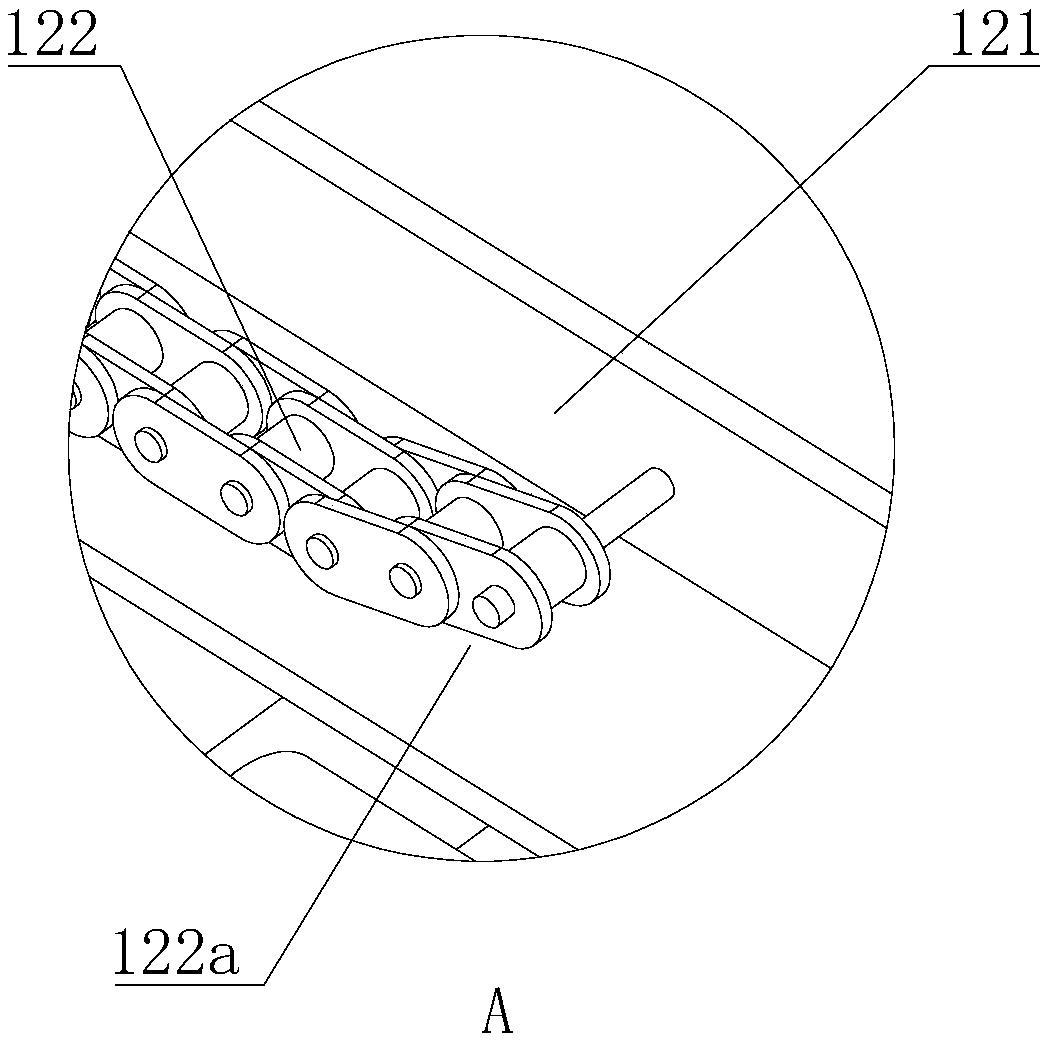

[0046] See attached figure 1 And attached figure 2 , a paper disc forming machine, including a frame 100, a stamping die 200 installed on the frame 100, a cardboard bin 110 corresponding to the stamping die 200, and a guide rail group 120 between the cardboard bin 110 and the stamping die 200 , the vacuum suction cup device 300 located below the cardboard bin 110 and transferring the cardboard in the cardboard bin 110 to the guide rail set, and the cardboard pushing device 400 for pushing the cardboard on the vacuum suction cup device 300 into the stamping die 200 . In this embodiment, the paper disc forming machine of the present invention has two stamping dies 200, two cardboard bins 110 and two guide rail sets 120, and a bottom of the cardboard bin 110 is provided with a bottom of the cardboard bin 110. The vacuum suction cup device 300 for sucking the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com