Exterior rearview mirror mounting bracket and mounting structure thereof

A technology of exterior rearview mirror and mounting bracket, which is applied in the field of automobile manufacturing, can solve the problems such as difficulty in meeting the requirements of rigidity and local mode of the mounting point, inability to see the rear external information, affecting the normal use of the rearview mirror, etc. Shorten the development cycle, prevent the rearview mirror from shaking, and have the effect of simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

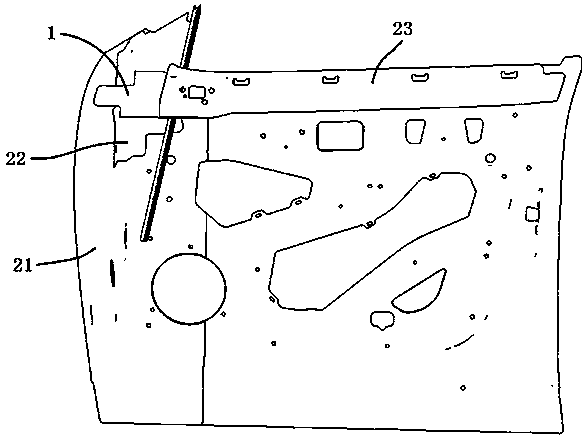

[0019] This embodiment proposes an exterior rearview mirror mounting bracket and its installation structure with better rigidity and strength, which is used to arrange the rearview mirror at the upper left corner of the outer panel (lock side) to improve the stability of the exterior rearview mirror sex.

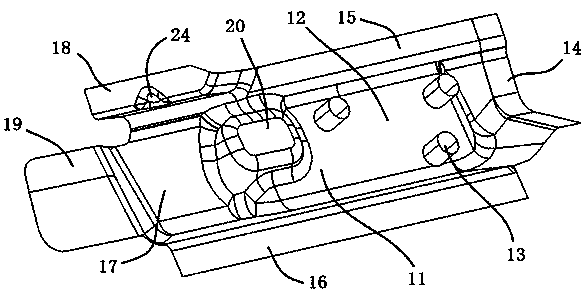

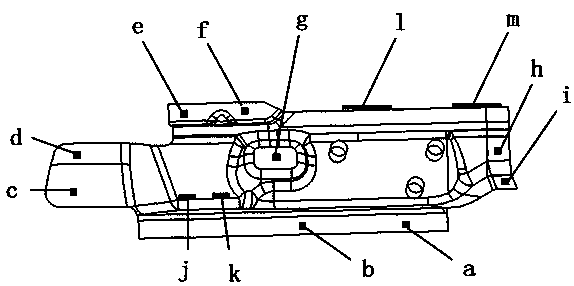

[0020] Such as figure 1 As shown, the exterior rearview mirror mounting bracket 1 of the present embodiment includes a plate-shaped main body 11, the periphery of the main body 11 is provided with a welding surface suitable for the corresponding position profile, and the middle part of the main body 11 is provided with a mounting bracket for fixing the exterior rearview mirror. The installation area 12 has a height difference between the installation area 12 and the welding surface, so that the exterior rearview mirror mounting bracket 1 forms an open box-like structure; the inner surface of the installation area 12 passes through the position corresponding to the rear exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com