Ultra-large floating body single module capable of achieving quick splicing and assembling structure thereof

A rapid splicing and super-large technology, which is applied in transportation and packaging, ship parts, ships, etc., can solve the problems of difficulty in the construction of large floating bodies, achieve the effect of compact structure, ensure safety, and increase construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

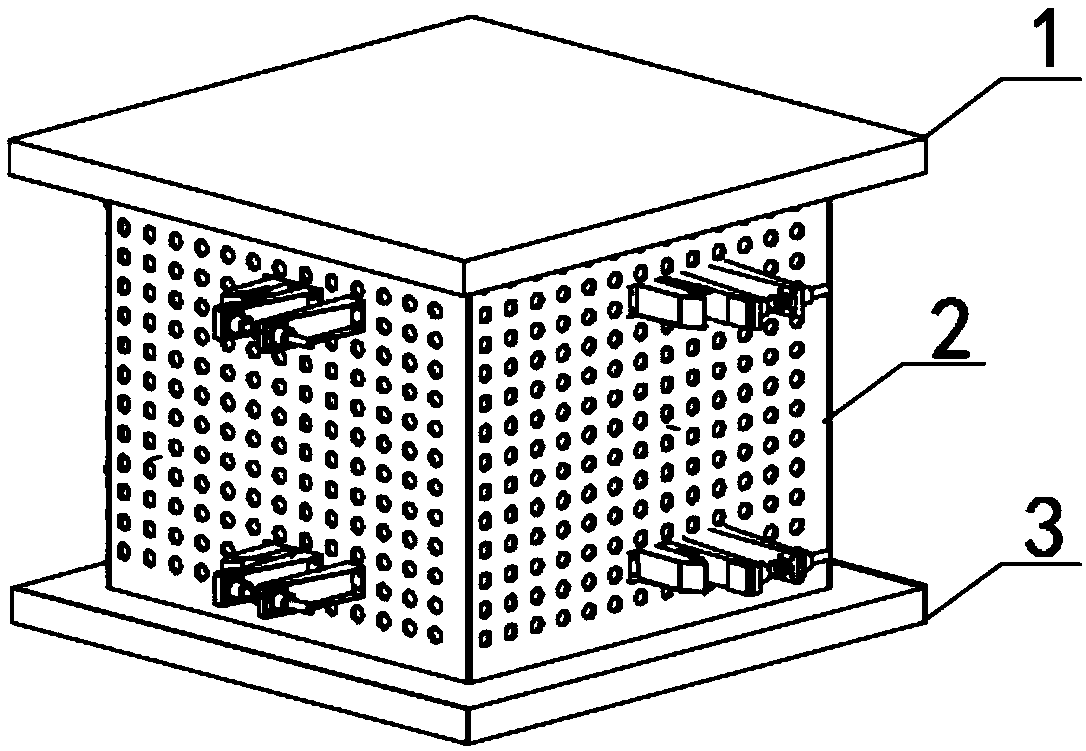

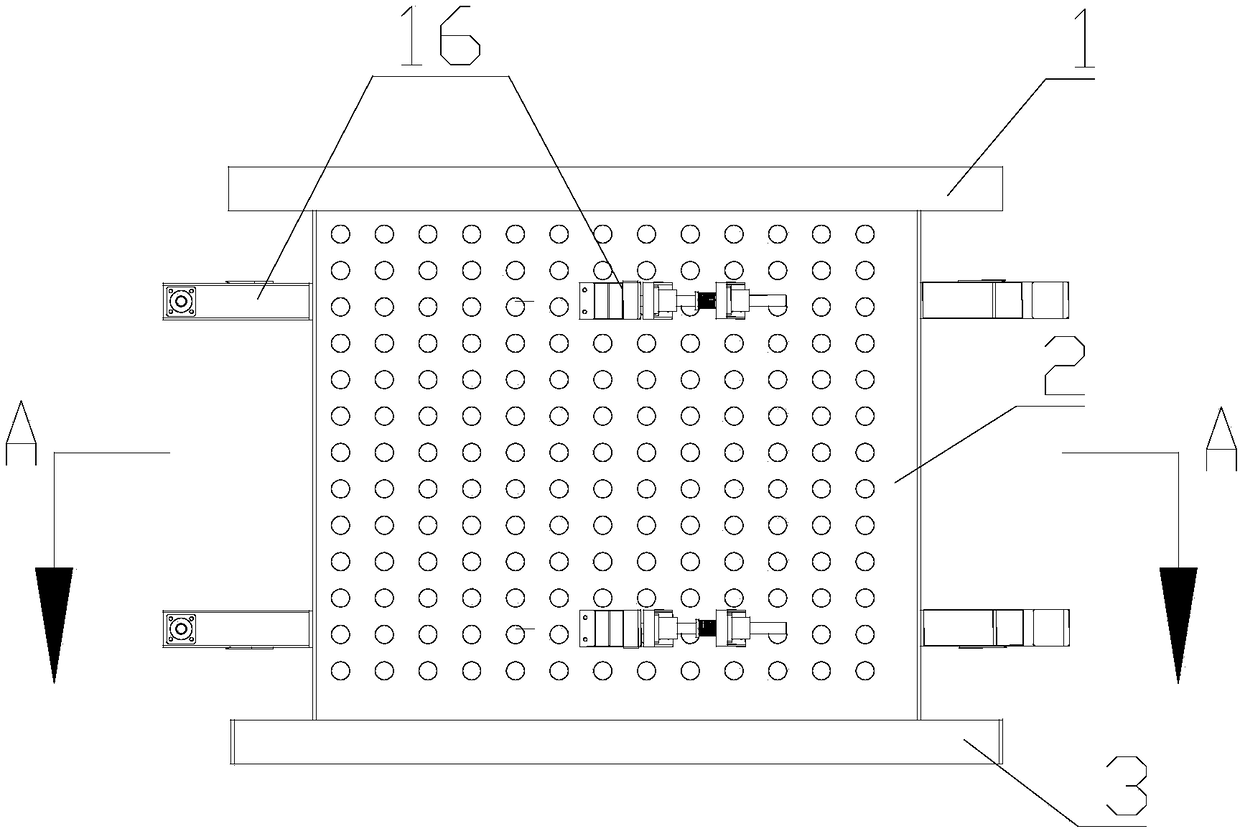

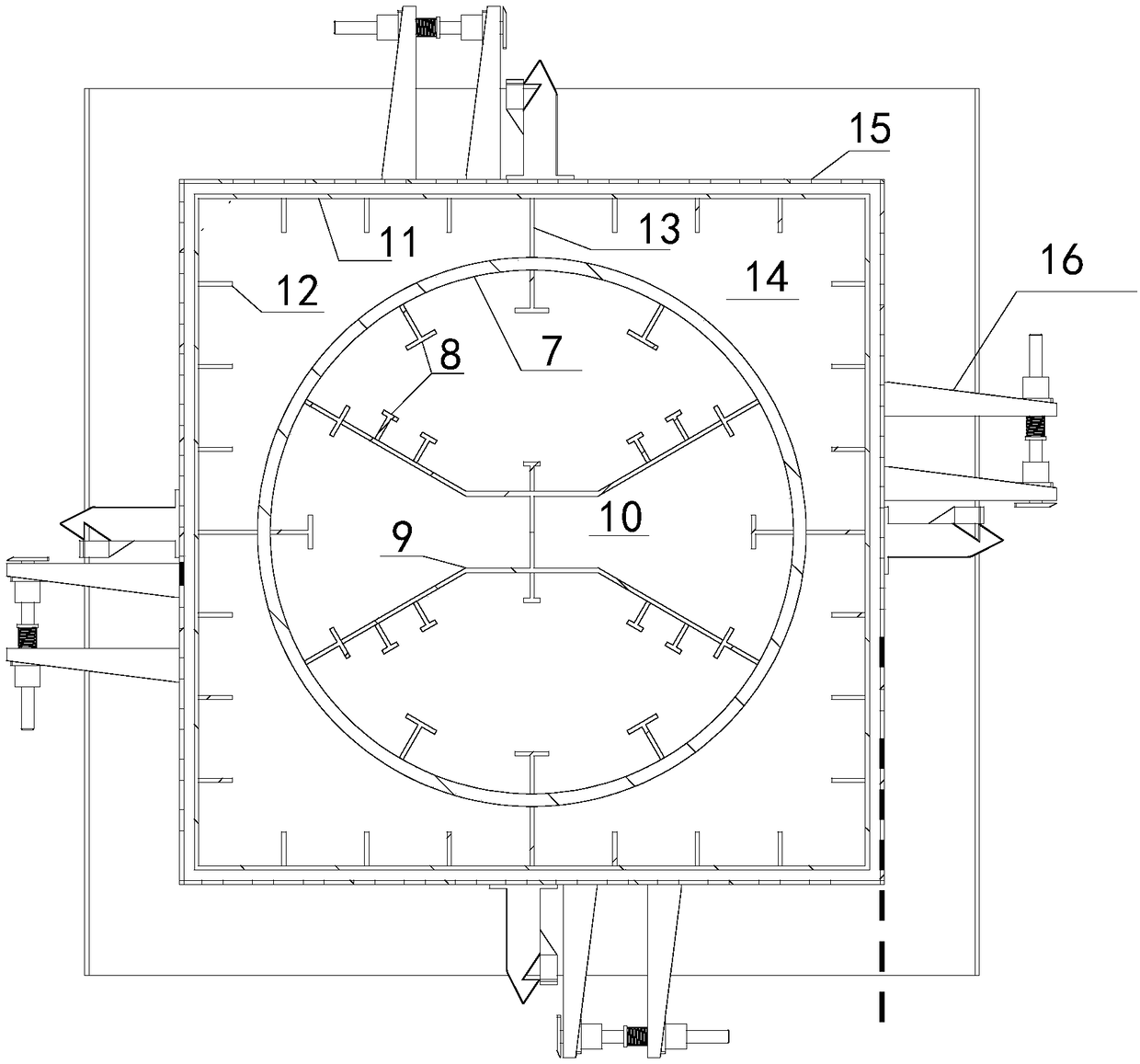

[0032] Such as Figure 1~6 As shown, the floating body single module provided by this embodiment includes an upper platform 1, an intermediate cylinder body 2, and a lower platform 3 from top to bottom, and the three layers are welded into one, which ensures that the overall structure has a certain ability to resist wind and waves.

[0033] The upper platform 1 and the lower platform 3 adopt the same structure, and the above platform 1 is taken as an example for illustration, such as Figure 4 As shown, the upper platform 1 includes two layers of platform panels 4 arranged in parallel, and a W-shaped plate 6 sandwiched between the two layers of platform panels 4 to support and strengthen. The two-layer platform panel 4 is a square with a side length of 21.2m, and the end faces around it are sealed with a water-tight plate 5, so that the entire upper platform 1 is watertight and prevents seawater from seeping. The platform panel 4 of the upper platform 1 adopts a high-strength...

Embodiment 2

[0046] Such as Figure 7 As shown, the assembly structure of the ultra-large floating body single module provided in this embodiment includes a plurality of said floating body single modules 23, and each floating body single module 23 adopts the floating body single module in Embodiment 1, and two adjacent floating body single modules The single floating body modules 23 are butted together through respective quick connectors 16 .

[0047] The specific assembly process of the floating body single module 23 is as follows: first, the floating body single module 23 built on land is transported to the sea area to be assembled, and the floating state of the floating body single module 23 is adjusted so that the two floating body single modules 23 to be spliced can be assembled quickly. The connectors 16 are located approximately at the same height. Then the two floating body single modules 23 are approached by traction. During the approaching process, the guide shaft 20 will guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com