Low-consumption continuous clean activated carbon production device and method

A clean production and activated carbon technology, applied in the direction of climate sustainability, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of high consumption of activators, power consumption, equipment corrosion, etc., and achieve enrichment of mesopores and micropores Pore structure, reduced consumption, and reduced energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

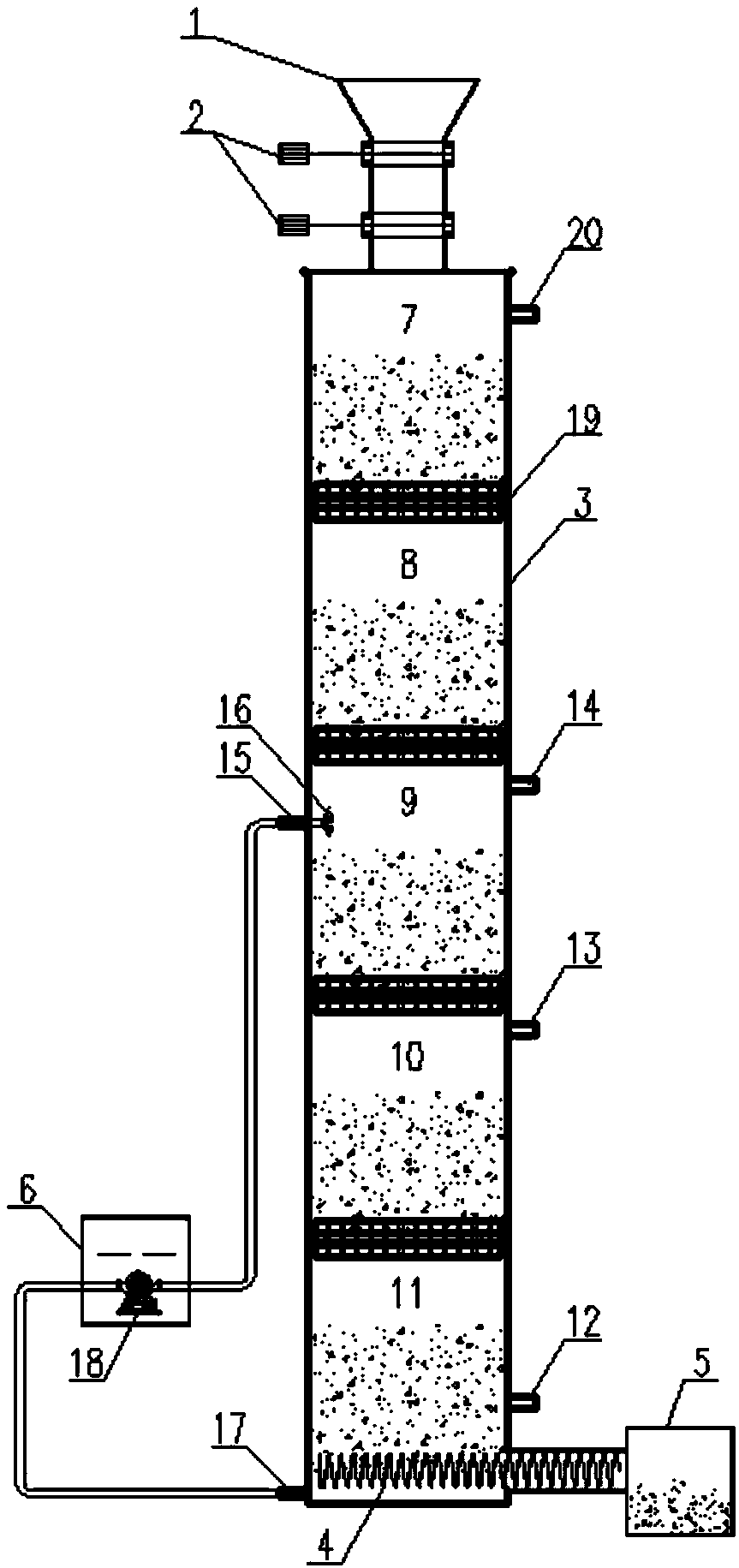

[0026] The raw materials in the supply hopper 1 are sent to the internal drying zone 7 and the pyrolysis zone 8 of the pyrolysis and activation integrated device 3 through the double-sealed feeding device 2. During the feeding process, the height of the remaining material in the supply hopper 1 is kept above 200mm, and the raw materials will fall A material layer is formed on the material interlayer 19. Only during the start-up process of the blanking interlayer 19, the material will fall in large quantities. The raw materials in the pyrolysis and activation integrated device 3 undergo pyrolysis reaction, producing pyrolysis gas, tar and semi-coke. The coke falls into the surface activation zone 9 through the blanking compartment 19, and the pyrolysis gas and tar flow upward in gaseous form. During the flow, the tar will condense when it is cold. After multiple reformings, the tar is removed and completely cracked into small molecular pyrolysis Gas, semi-coke, and small molecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com