Titanium tetrachloride oxidation reactor feeding structure

An oxidation reactor, titanium tetrachloride technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of uneven momentum ratio of cloth, control difficulty, etc., to prevent scarring, avoid deposition and aggregation, and is conducive to The effect of granular control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

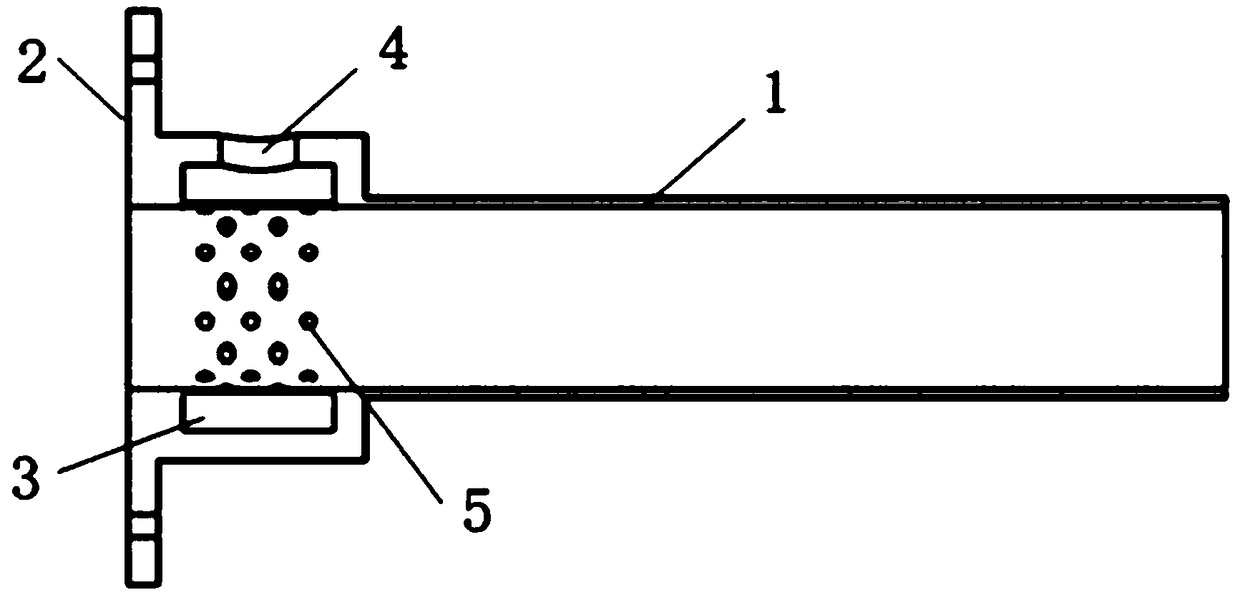

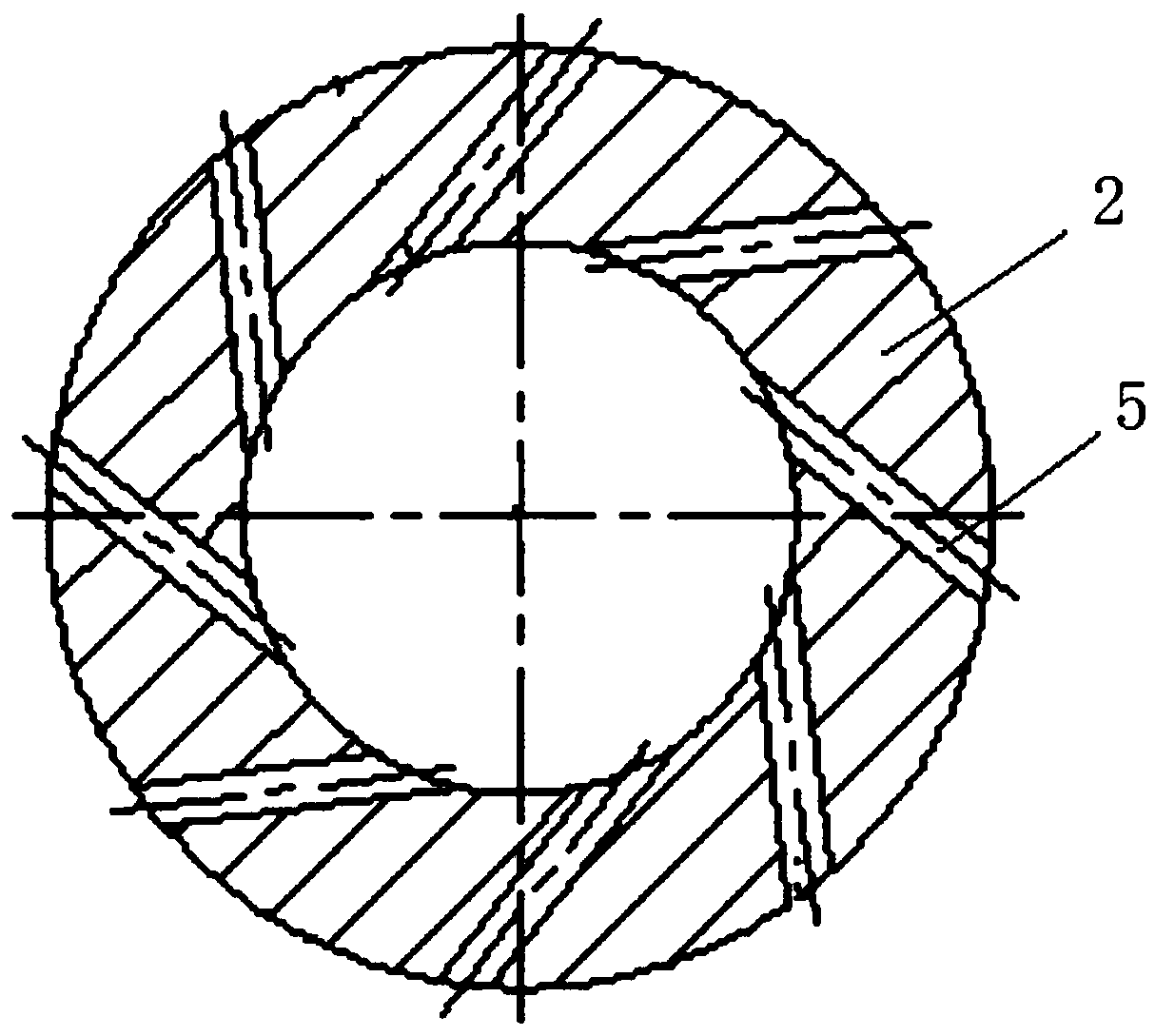

[0015] like figure 1 , figure 2 As shown, the titanium tetrachloride oxidation reactor feed structure of the present invention comprises a feed gas curtain chamber 2, and one end of the feed gas curtain chamber 2 is communicated with the end 1 of the oxidation furnace, and the other end is communicated with the reaction chamber. A plurality of air curtain holes 5 are arranged on the wall surface of the feed air curtain chamber 2 , and the axes of the air curtain holes 5 are arranged tangentially along the inner wall surface of the feed air curtain chamber 2 . The inner wall of the feed gas curtain chamber 2 is preferably consistent with the inner diameter of the end 1 of the oxidation furnace to avoid gas turbulence. One end of the feed gas curtain chamber 2 can be sleeved on the end 1 of the oxidation furnace, and the other end is connected to the reaction chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com