Slope self-adaptive spherical support

A spherical bearing, self-adaptive technology, applied to bridge parts, bridges, buildings, etc., can solve problems such as endangering bridge structure safety, pier deviation, bearing damage, etc., to achieve convenient repair and maintenance, bridge structure safety, and energy saving The effect of the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

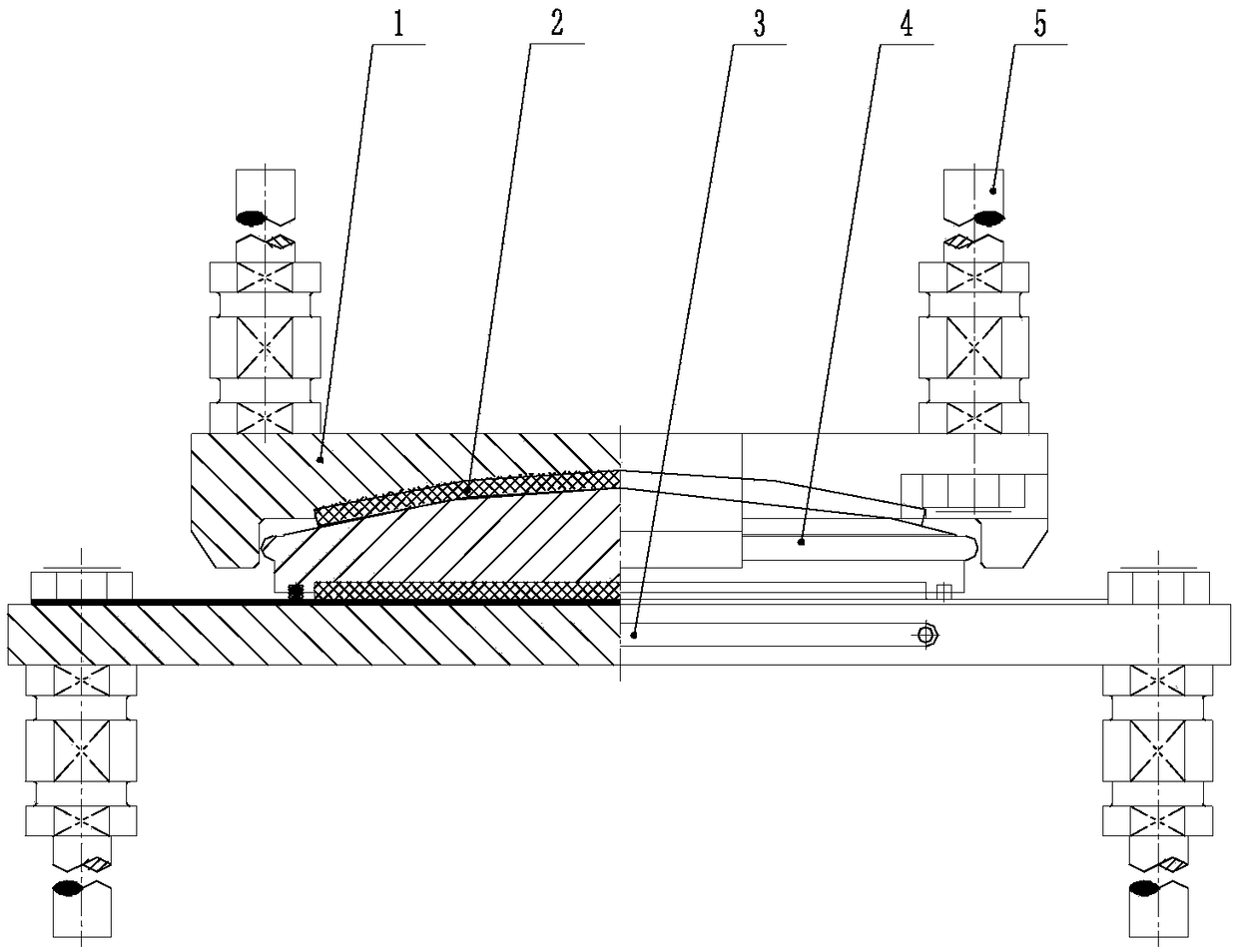

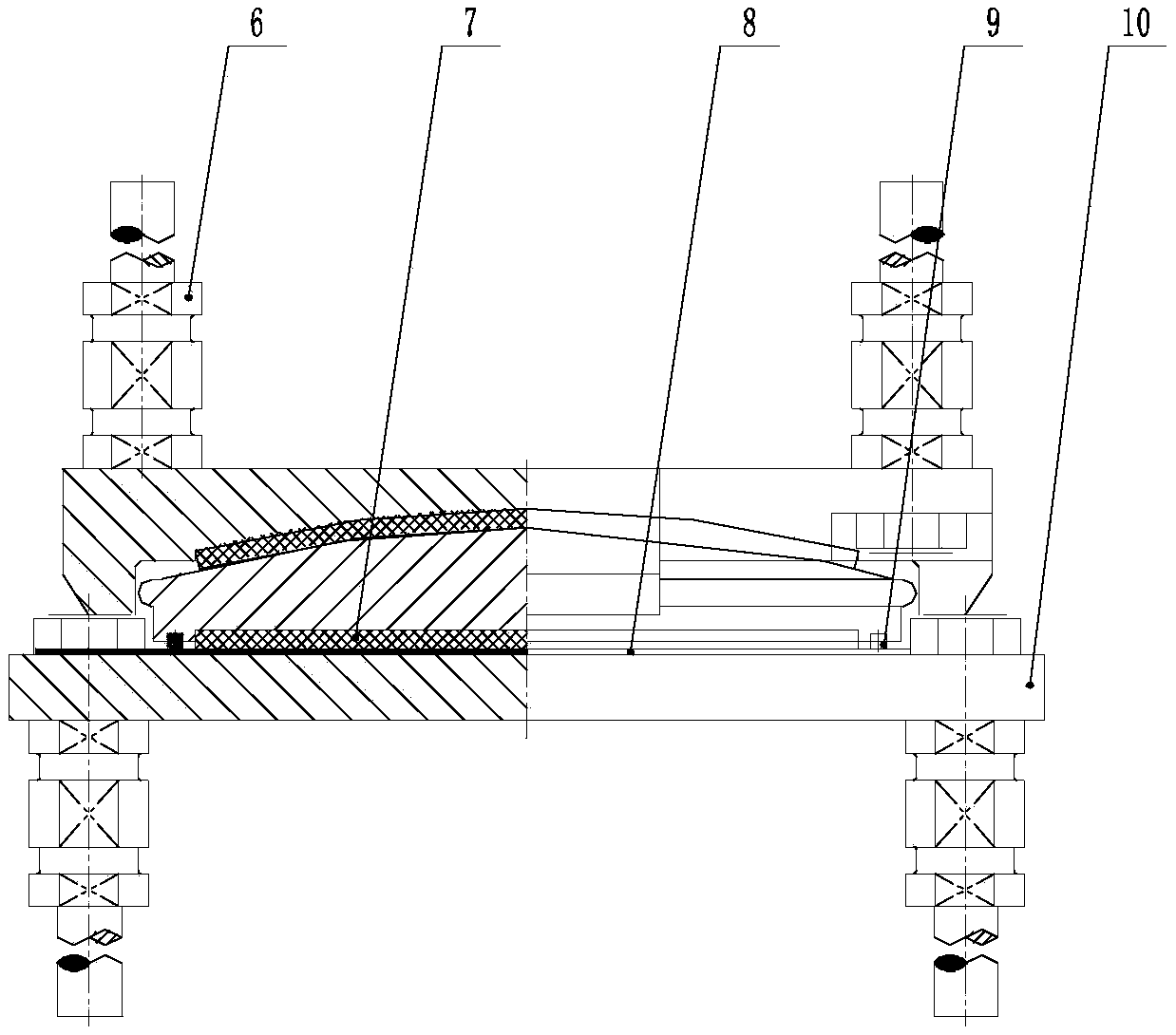

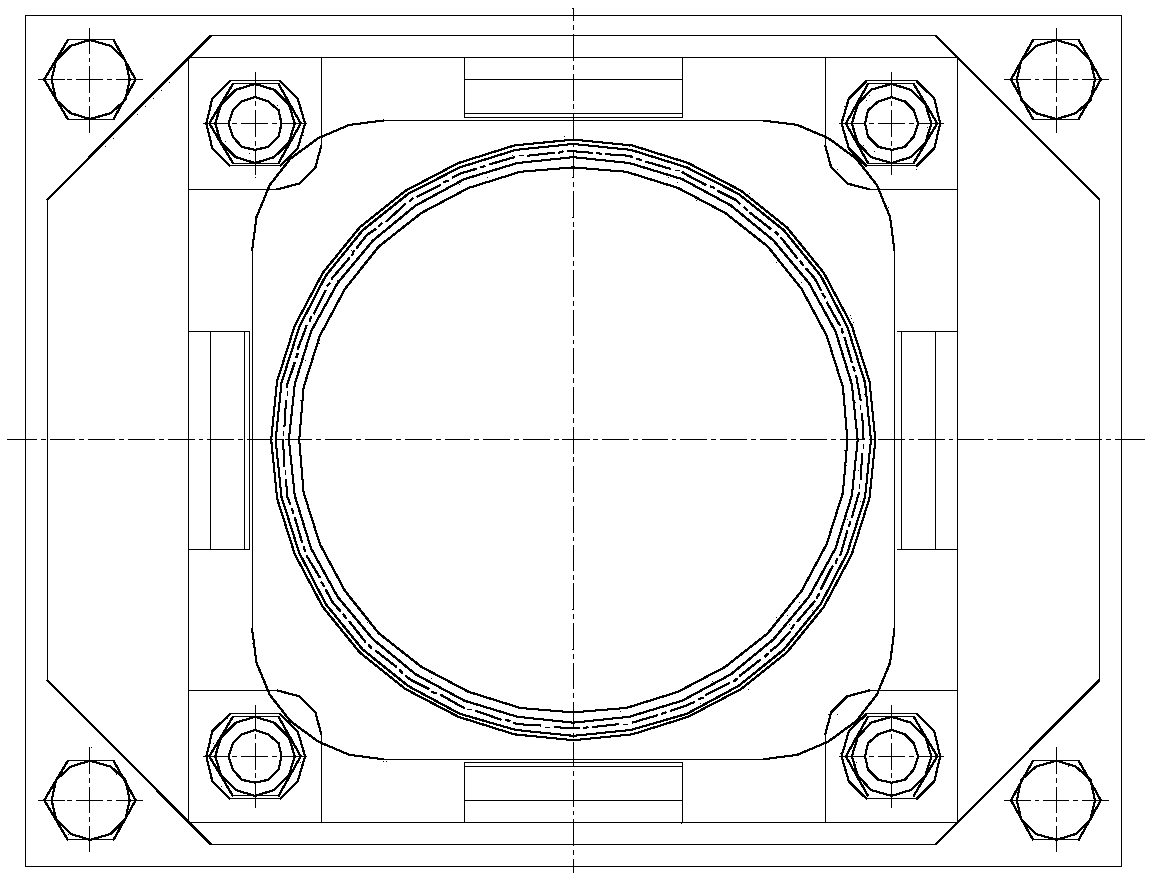

[0026] A slope self-adaptive spherical bearing, comprising an upper base plate 1 and a lower base plate 10, an arc-shaped upwardly protruding spherical bearing 4 is arranged on the lower base plate 10, the upper base plate 1 is arranged on the spherical bearing 4, and the upper base plate The bottom of 1 is provided with an inwardly recessed arc-shaped groove whose shape is compatible with the spherical support 4, and the arc-shaped groove is in contact with the spherical support 4. figure 1 5 in is the anchor rod, figure 2 6 of them are anchor rods.

[0027] The spherical bearing 4 is arranged on the lower seat plate 10 through the slide plate 8 and the spherical bearing 4 can slide on the slide plate 8 .

[0028] The bottom of the spherical support 4 is provided with a planar PTFE plate 7 , and the spherical support 4 is in contact with the slide plate 8 through the planar PTFE plate 7 . The bottom of the spherical support 4 is provided with a groove for assembling the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com