Sterile flush toilet water tank and control method

A technology for flushing toilets and water tanks, which is applied to flushing equipment with water tanks, water supply devices, buildings, etc., can solve problems such as polluting toilet supplies, and achieve the effect of prolonging service life, eliminating bacterial growth, and avoiding the phenomenon of bacterial growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

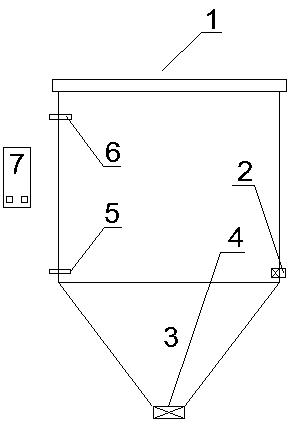

[0009] Embodiment 1: with reference to attached figure 1 . A kind of aseptic flush toilet water tank, comprises flush toilet water tank 1, and flush toilet water tank 1 is provided with drain valve 4, water inlet valve 2 and controller, and the lower part of described flush toilet water tank 1 is provided with low water level sensor 5, and the upper part of flush toilet water tank 1 is provided with high Water level sensor 6, the signal output terminals of low water level sensor 5 and high water level sensor 6 are connected to the signal terminal of controller 7 through connecting wires, and the controller is provided with large and small water switch keys; a. large water switch key and high water level sensor The 6 signal connection terminal and the water inlet valve 2 signal connection terminal are connected in parallel and are used to control the high water level sensor 6 and the water inlet valve 2 to work or shut down and to control the water discharge valve 4 to close or...

Embodiment 2

[0011] Embodiment 2: On the basis of embodiment 1, the work of the large water switch key and the small water switch key all controls the exhaust fan; when the large water switch key or the small water switch key is turned on, the exhaust The fan works, when the big water switch key or the small water switch key is disconnected, the exhaust fan will stop working after a delay to the set time.

Embodiment 3

[0012] Embodiment 3: On the basis of the above embodiments, a control method for an aseptic flush toilet tank includes a controller. When the user needs to flush the flush toilet with flood water, press the flood switch key on the controller, and the controller instructs The electromagnetic water inlet valve opens the water inlet and instructs the high water level sensor to work. When the water level reaches the high water level, the high water level sensor transmits the detected high water level signal to the controller, and the controller instructs the electromagnetic water inlet valve to close; when the user finishes defecation , when the big water key is pressed again, the controller instructs the high water level sensor to stop working, the electromagnetic water inlet valve is closed, and at the same time, instructs the drain valve to open and flush the toilet. When the user needs to flush the toilet with small water, press the small water switch key, the controller instru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com