A kind of sic fiber variable angle reinforced ti-matrix composite tube and shaft part and its preparation method

A composite material tube and composite material technology, which is applied in the field of SiC fiber variable-angle reinforced Ti-based composite material tube and shaft parts and its preparation, can solve the problem of poor shear resistance and torsion resistance, and the inability to achieve densification of the entire layer of precursor filaments. Problems such as little practical significance, to achieve the effect of improving mechanical properties, reducing quality, and reducing the degree of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

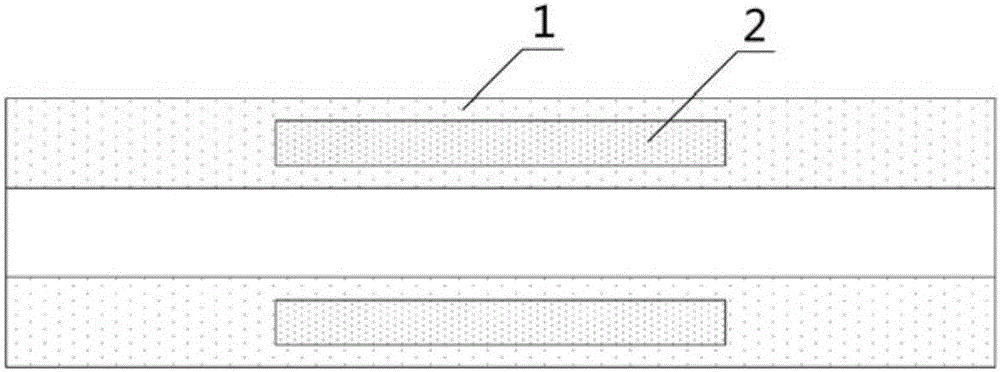

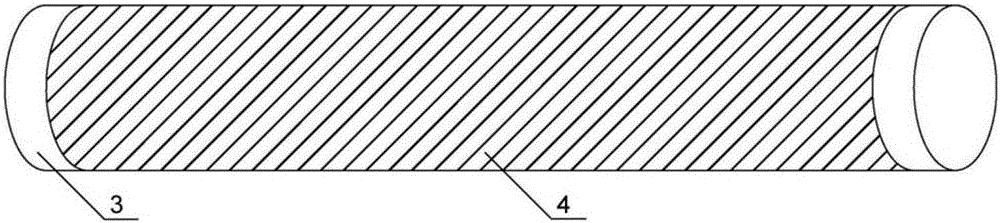

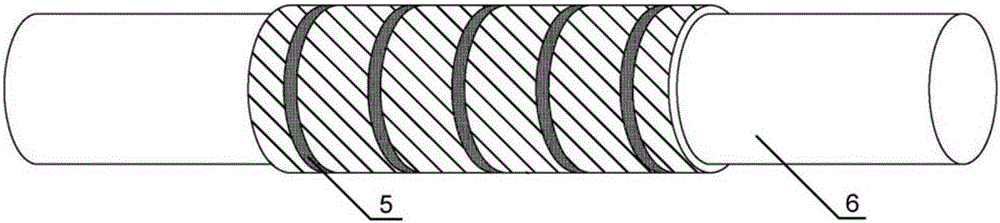

[0048] SiC f / TC17 composite material[45°,-45°] 3 The preparation steps and process of the tubular shaft parts are as follows:

[0049] 1) Use alcohol to clean the surface of the continuous SiC fiber, then wind the fiber on the sample holder of the magnetron sputtering equipment, put it into the magnetron sputtering equipment, use TC17 titanium alloy target; mechanical pump, molecular pump pre-evacuation chamber , the vacuum degree is better than 1×10 -3 After Pa, heat the vacuum chamber at 500°C and bake it. When the vacuum degree reaches the requirement, flow Ar gas, rotate the sample holder at a speed of 20 rpm, start the sputtering power supply, and start magnetron sputtering to produce SiC / TC17 precursor wire. , the target-base distance is 30mm, the single target sputtering power is 1500W, the magnetron sputtering time is 12 hours, after the sputtering is finished, it is lowered to room temperature, and the precursor wire is taken out. The diameter of the precursor wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com