Embedded-keel-type radiant floor heating structure and laying method thereof

A keel-type floor heating technology, applied in the field of interior decoration, can solve the problems of poor user experience, easily damaged floor heating heating pipes, long laying period, etc., and achieve the effects of convenient, fast and safe construction, balanced and comfortable ground temperature, and easy assembly and combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

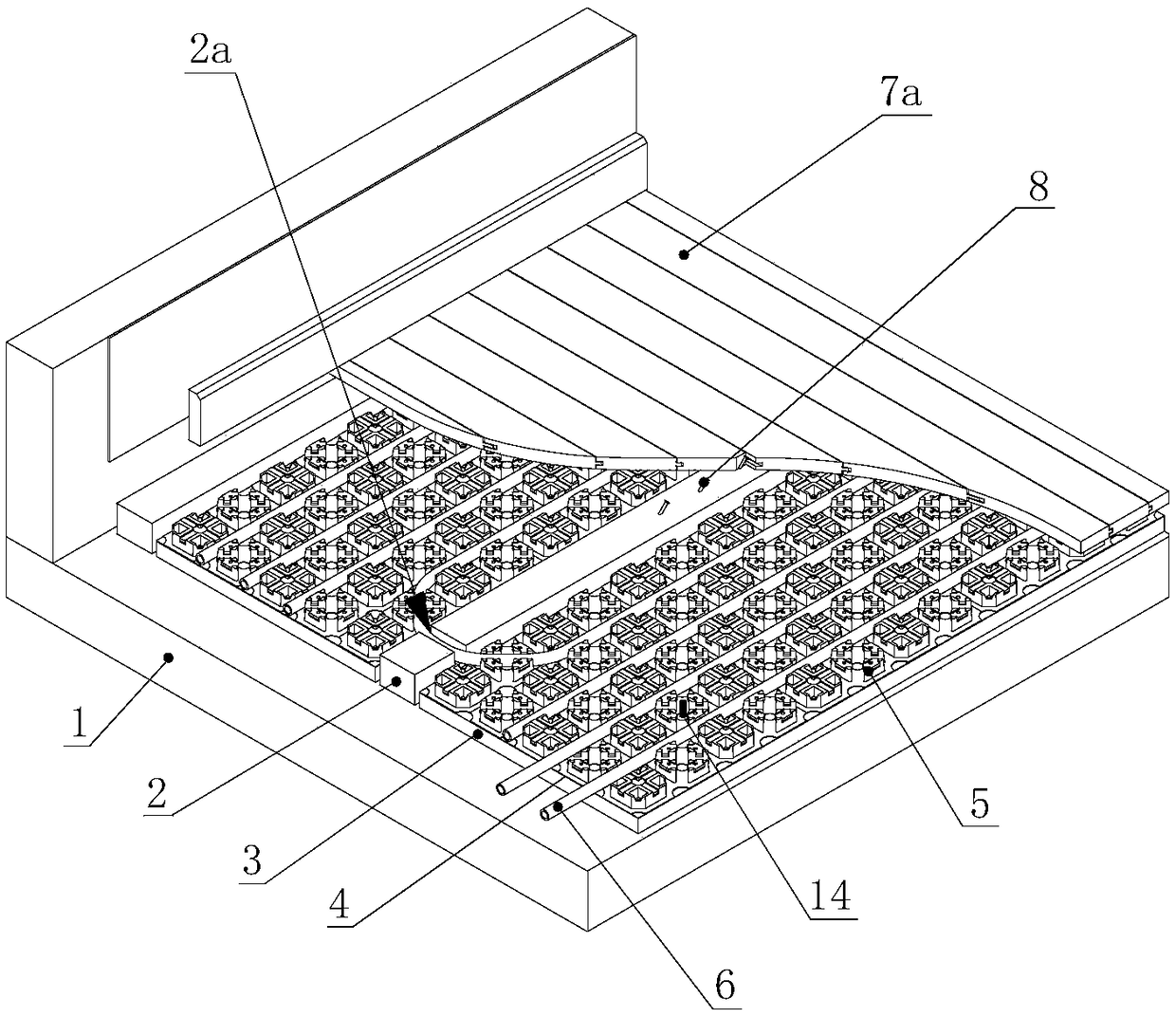

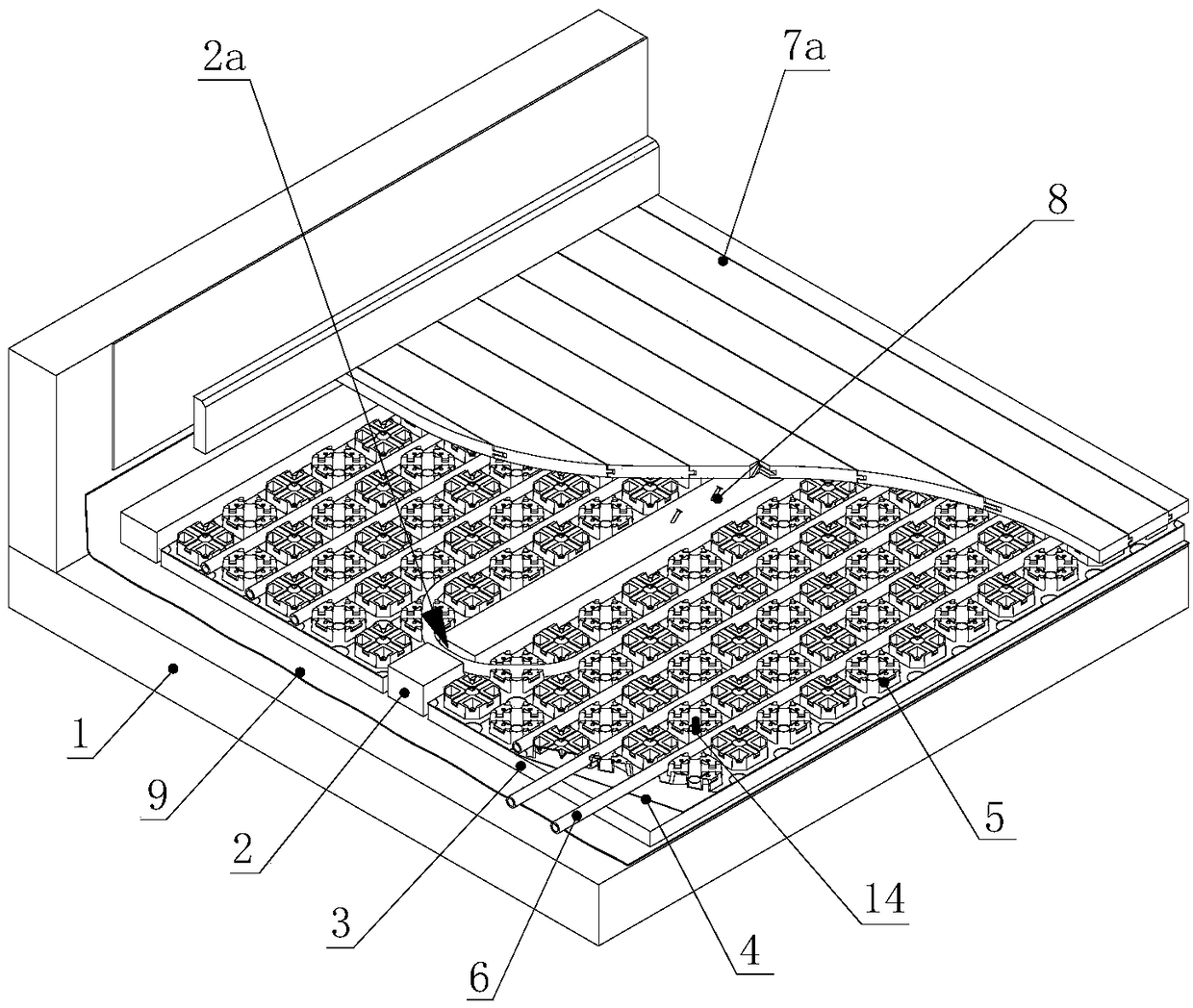

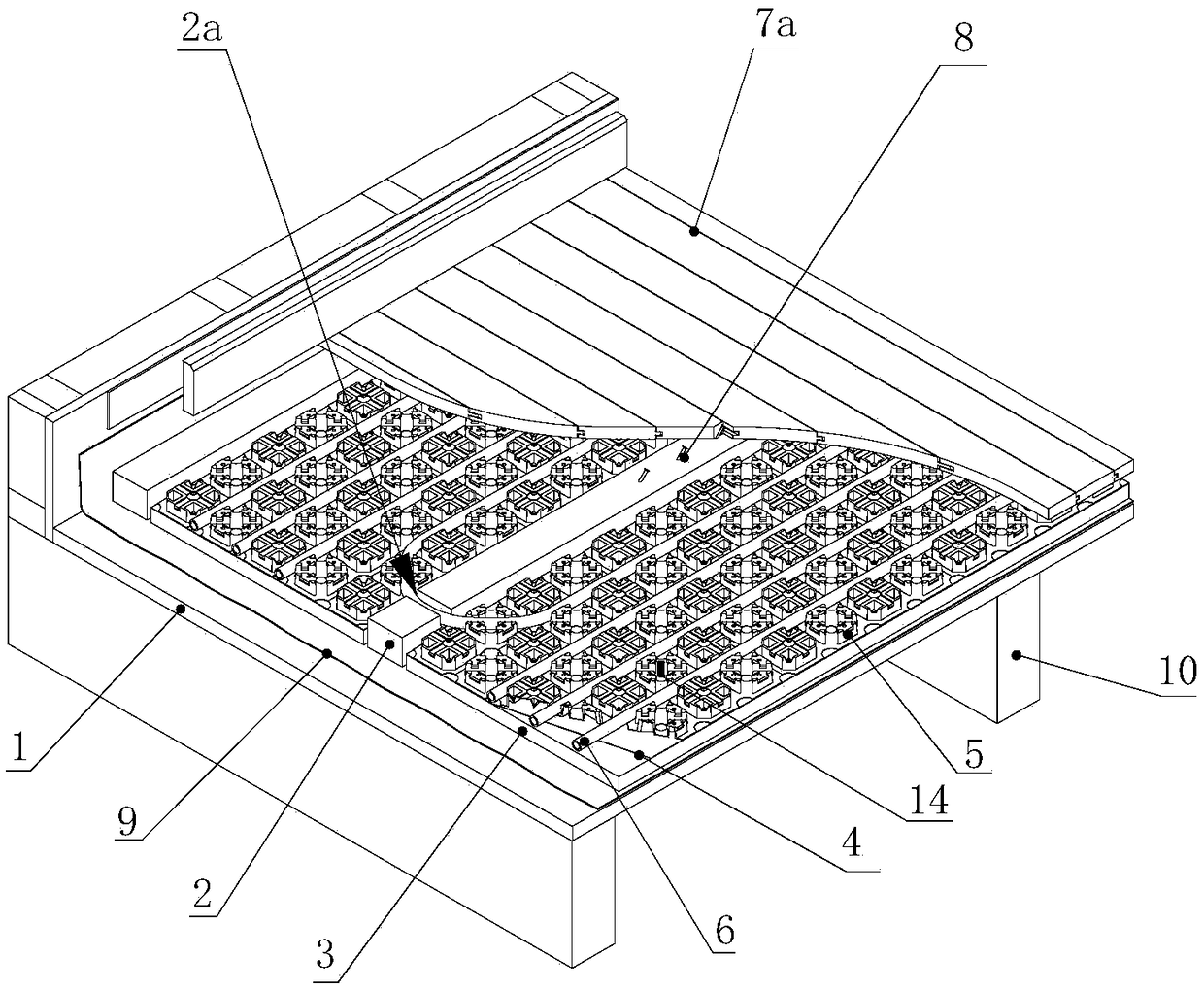

[0051] Such as Figure 1-10 Shown: an embedded keel type floor heating structure, set on the building floor 1, including ground keel 2, insulation board 3, reflective heat transfer adhesive film 4, prefabricated rubber pad 5, floor heating heating pipe 6, and floor plate;

[0052] The ground keel 2 is fixed on the upper side of the floor 1 according to the floor slab paving requirements and is provided with a fixing groove 2a for fixing the floor heating heating pipe 6;

[0053] The thermal insulation board 3 is embedded between the 2 ground keels and between the ground keel 2 and the building wall or directly attached to the lower side of the floor 1;

[0054] The reflective heat transfer adhesive film 4 is pasted on the floor 1 or the insulation board 3 between the ground keels 2 and between the ground keel 2 and the building wall;

[0055] The prefabricated rubber pad 5 is pasted on the reflective heat transfer adhesive film 4;

[0056] The water inlet pipe 6a and the ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com