Iodine satellite thruster working medium supply system and application method thereof

A technology for supplying systems and thrusters, which is applied to machines/engines, jet propulsion devices, rocket engine devices, etc., can solve problems such as blocking propellant delivery lines, and achieve the effect of simple and reliable application and high propulsion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

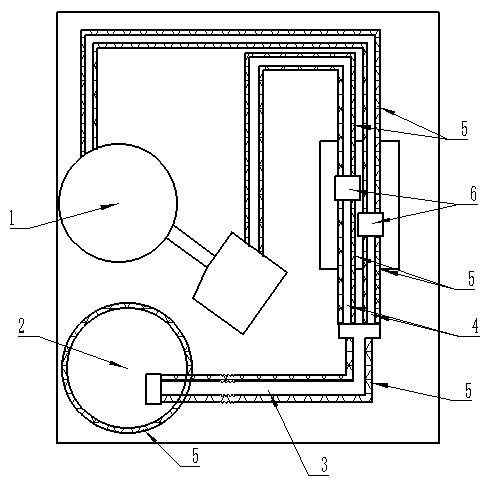

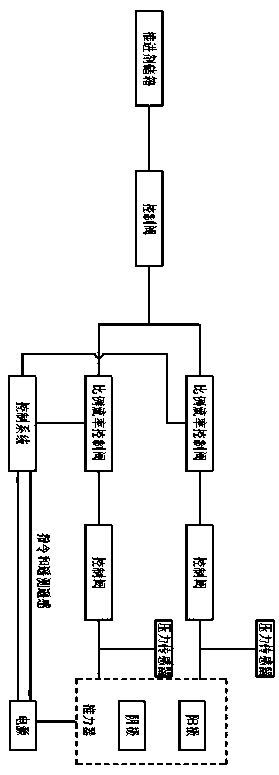

[0020] Such as figure 1 figure 2 As shown, a working medium supply system of an iodine satellite thruster 1 includes a propellant storage tank 2 located at the rear end of the thruster 1, and the propellant storage tank 2 is communicated with a main pipe 3, and the main pipe 3 is divided into two branches by a three-way valve. Two branch pipes 4, the two branch pipes 4 are respectively connected to the cathode and anode of the thruster 1; the propellant storage tank 2, the main pipe 3, and the two branch pipes 4 are respectively equipped with a temperature-controllable heating device 5; the two branch pipes 4 are respectively A proportional flow rate control valve 6 is provided; a section of the main pipe 3 is a bellows, and the bellows is to adapt to the fluctuation of the tank cover of the propellant storage tank 2 when it is working. The heating device 5 is a flexible polyimide heater, and the heating device 5 is coated on the propellant tank 2, the main pipe 3 and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com