Integrated type LED light-emitting unit

A light-emitting unit and integrated technology, which is applied in the field of automotive lighting, can solve the problems of affecting the production efficiency of the assembly line process, complicating the assembly process, and poor wiring contact, so as to avoid poor wiring contact, save installation space, and simplify the assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

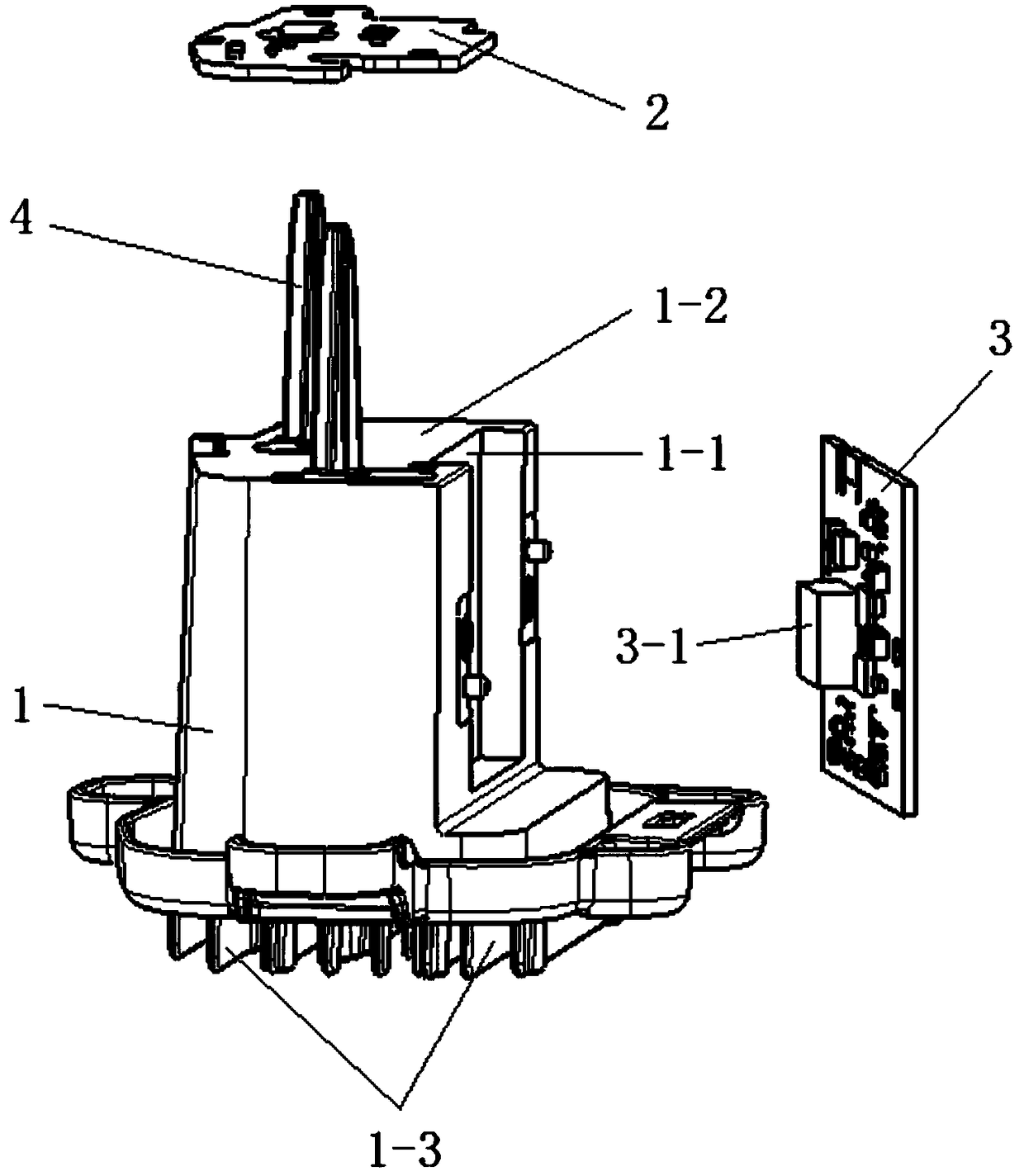

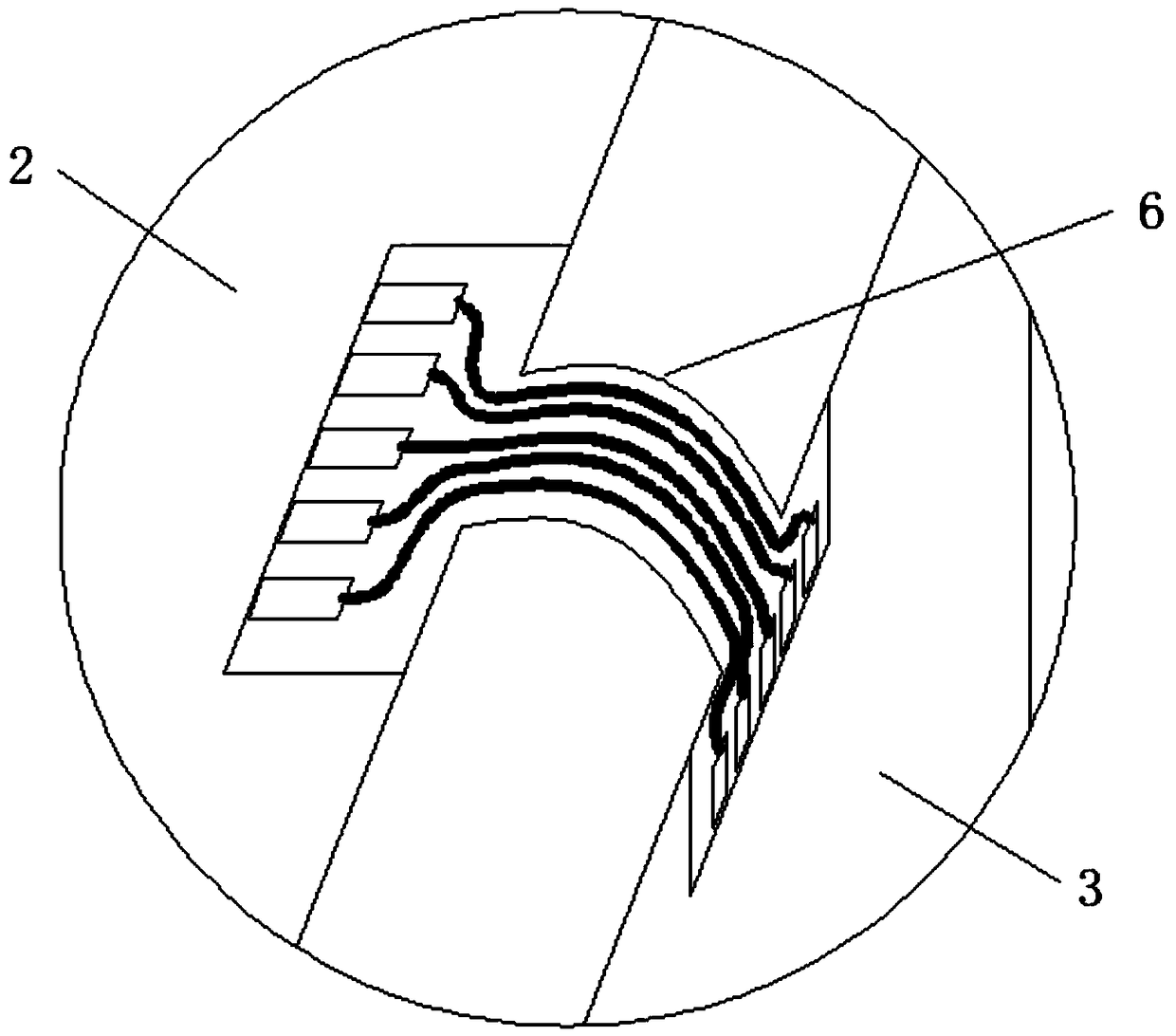

[0020] The invention discloses an integrated LED lighting unit, such as figure 1 As shown, it includes a radiator 1, an LED circuit board 2 and an LED control circuit board 3, the LED circuit board and the LED control circuit board are fixedly installed on the radiator, and the LED circuit board and the LED control circuit board maintain electrical connection. Owing to the omission of the dedicated bracket in the traditional LED control module, the space occupied by the entire LED lighting unit is reduced by at least 40%, which is conducive to meeting the development trend of miniaturization of vehicle lights.

[0021] The LED control circuit board is fixed on one side of the radiator, and the corresponding side of the radiator is made into a groove structure, and each component on the LED control circuit board is located in the groove structure in the installed state . A groove structure is provided on the heat sink to leave enough space for the components on the LED contro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap