Horizontal afterheat boiler capable of improving heat exchange efficiency

A waste heat boiler and heat exchange efficiency technology, which is applied in the field of horizontal waste heat boilers, can solve the problems of rusting and inconvenience in the furnace, and achieve the effects of reducing workload, improving heat exchange efficiency, and preventing improper operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

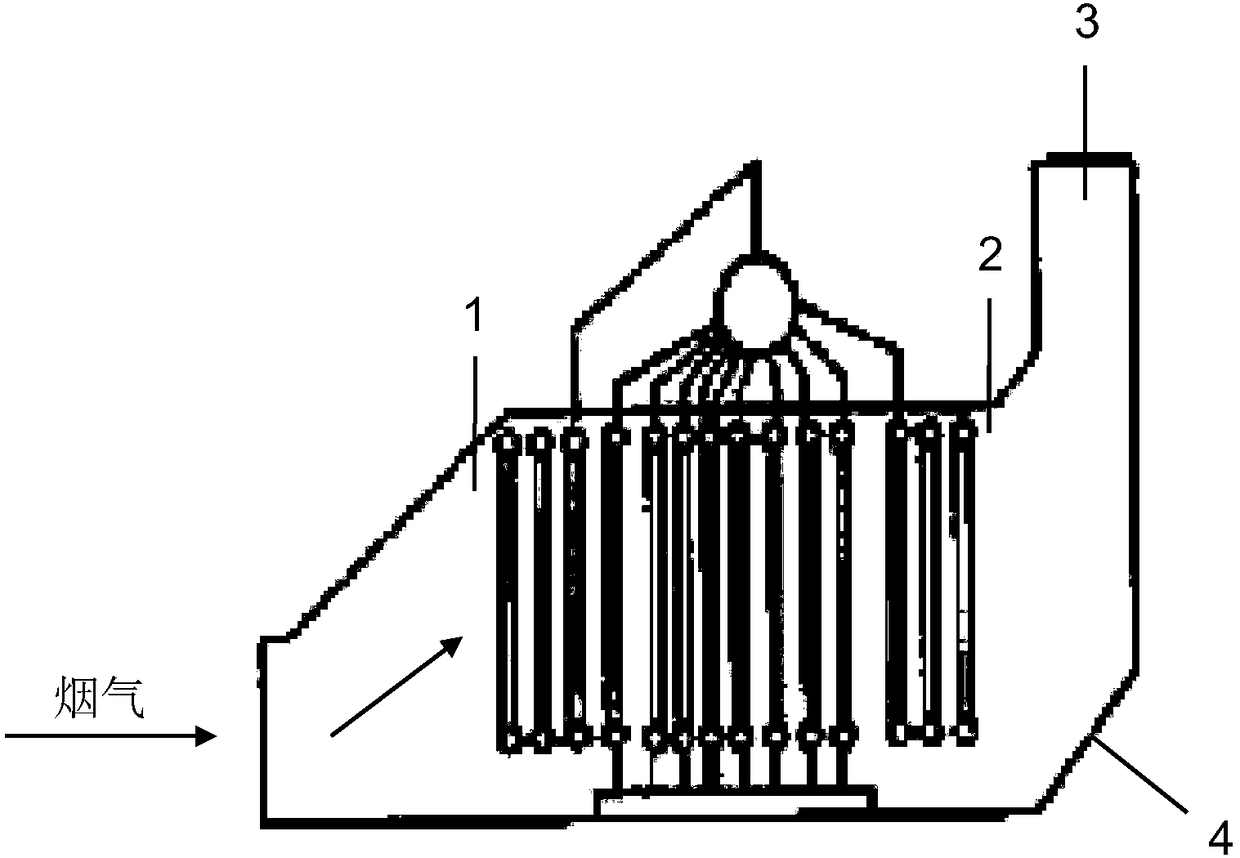

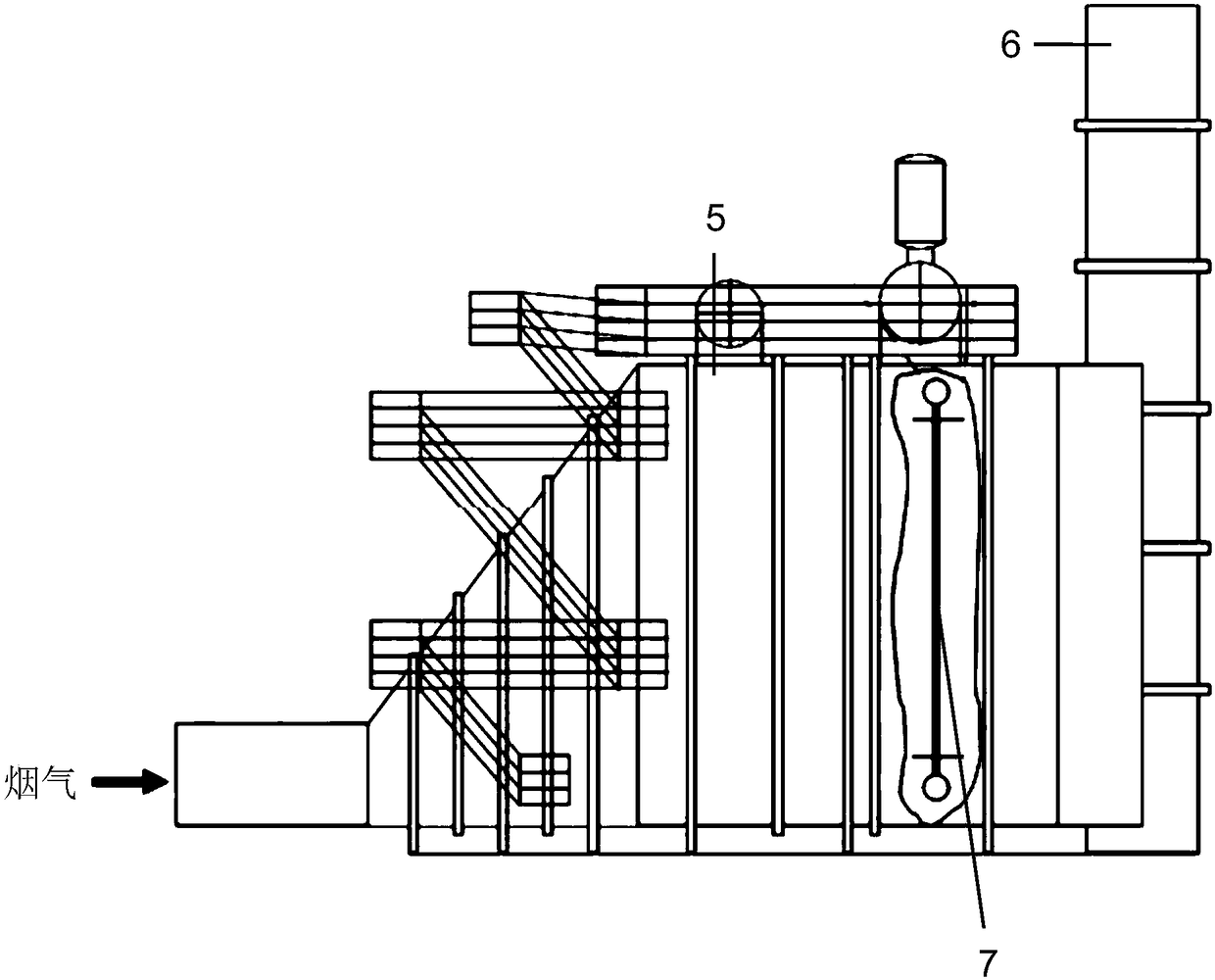

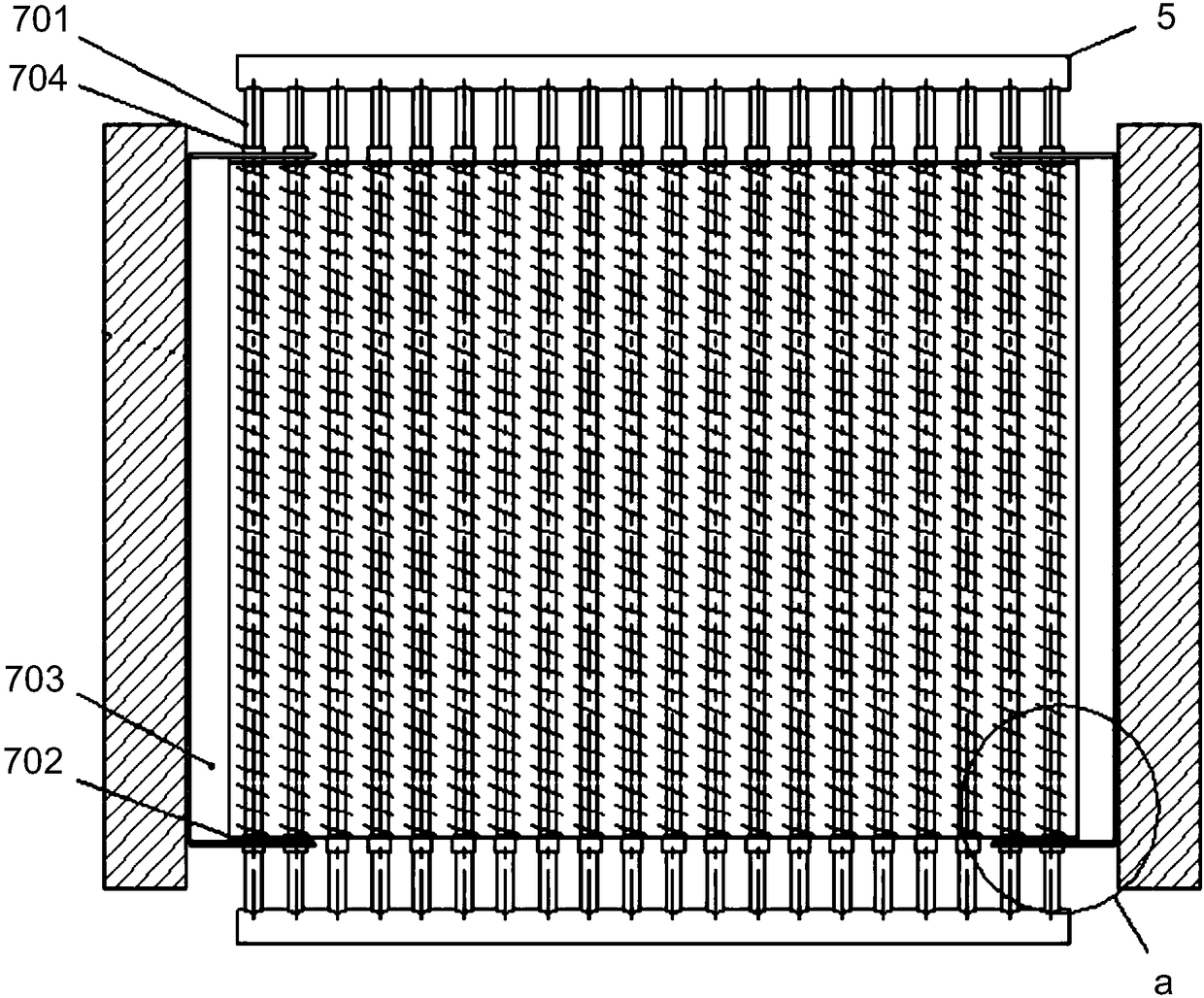

[0025] Please combine Figure 2 to Figure 7 As shown, a horizontal waste heat boiler capable of improving heat exchange efficiency provided by the present invention includes a boiler body 5 and a chimney 6 connected to the rear of the boiler body 5. There is a flue gas outlet in the boiler body 5, and the flue gas outlet A flue gas baffle 7 is arranged on it, and several water outlets are provided at the bottom of the boiler body 55, and a water outlet is also arranged on the chimney 6. The above-mentioned is a prior art part, and will not be repeated here. The difference from the prior art is that the flue gas baffle 7 includes heating surface tube bundles 701, spacer baffles 702 and side wing baffles 703. There are several heating surface tube bundles 701, and several heating surface tube bundles 701 are erected at even inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com