Multi-point testing and correcting device and rapid layout method

A calibration device and network point technology, which is applied in the direction of weapon testing, offensive equipment, weapon accessories, etc., can solve the problems of large accuracy errors and poor uniformity of testing devices, so as to ensure reliability, solve reading errors and operation errors, and reduce tediousness The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

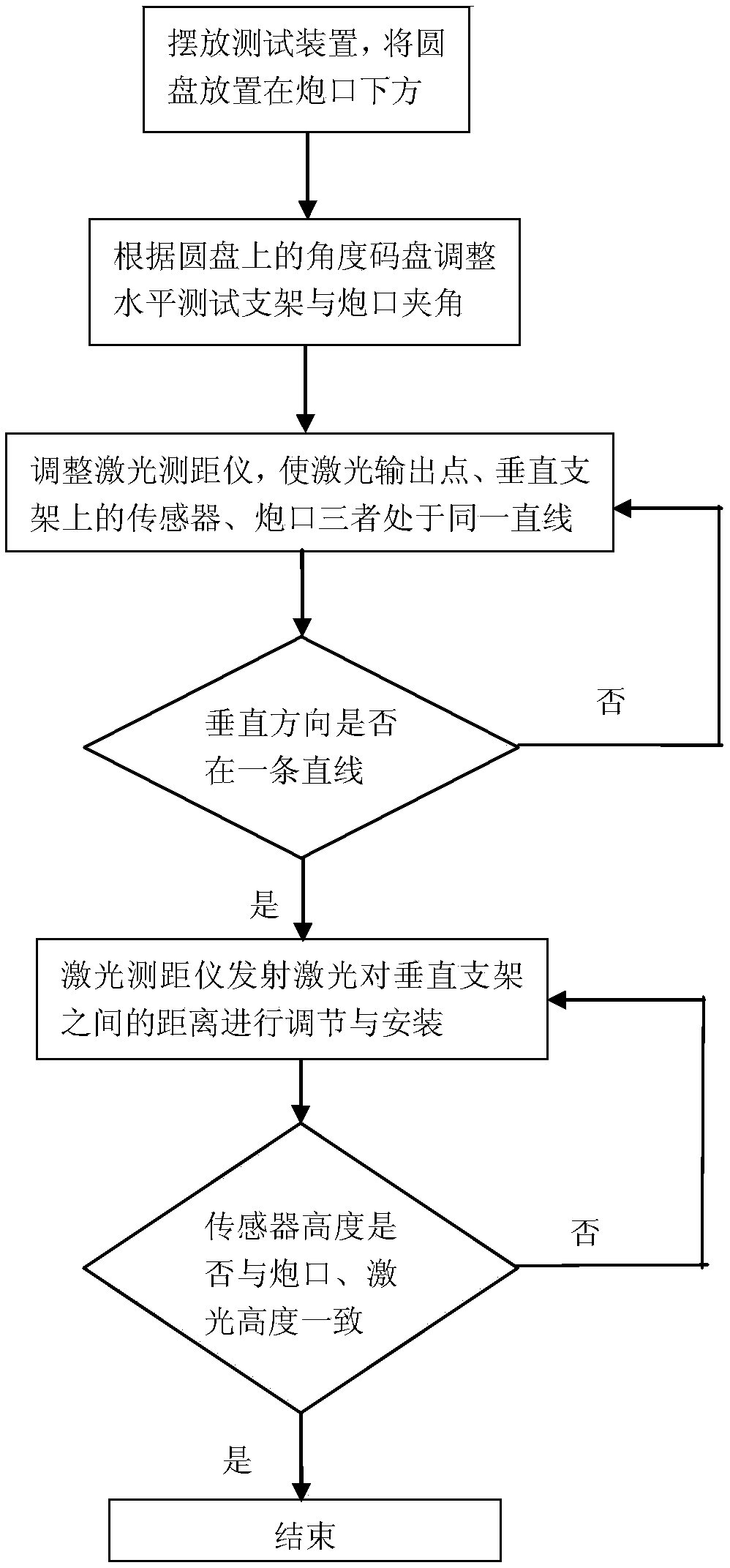

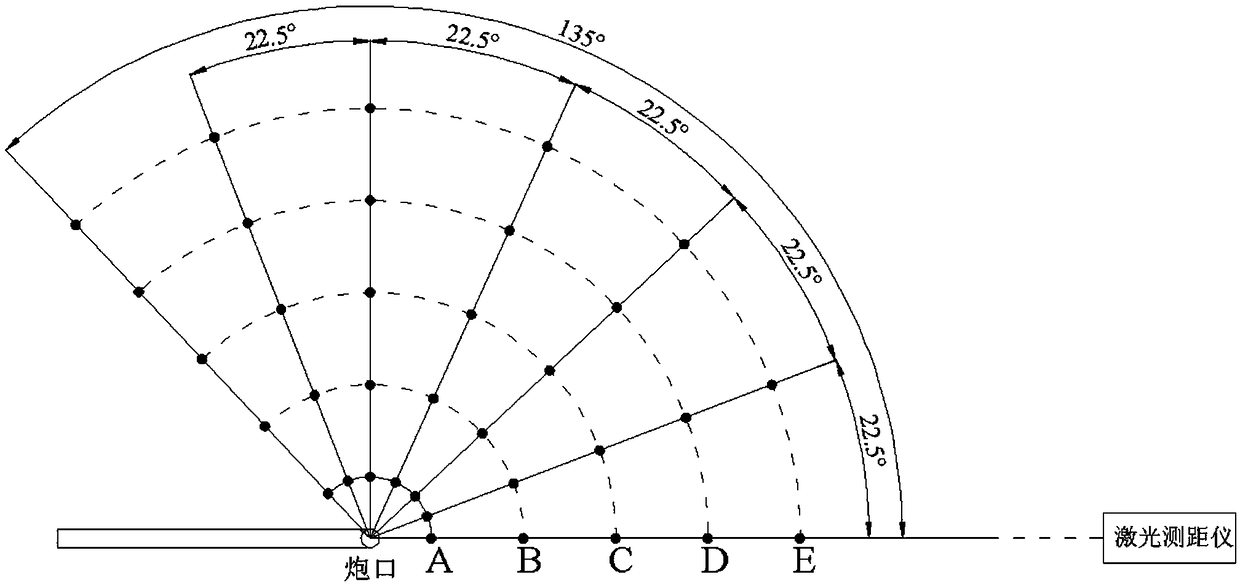

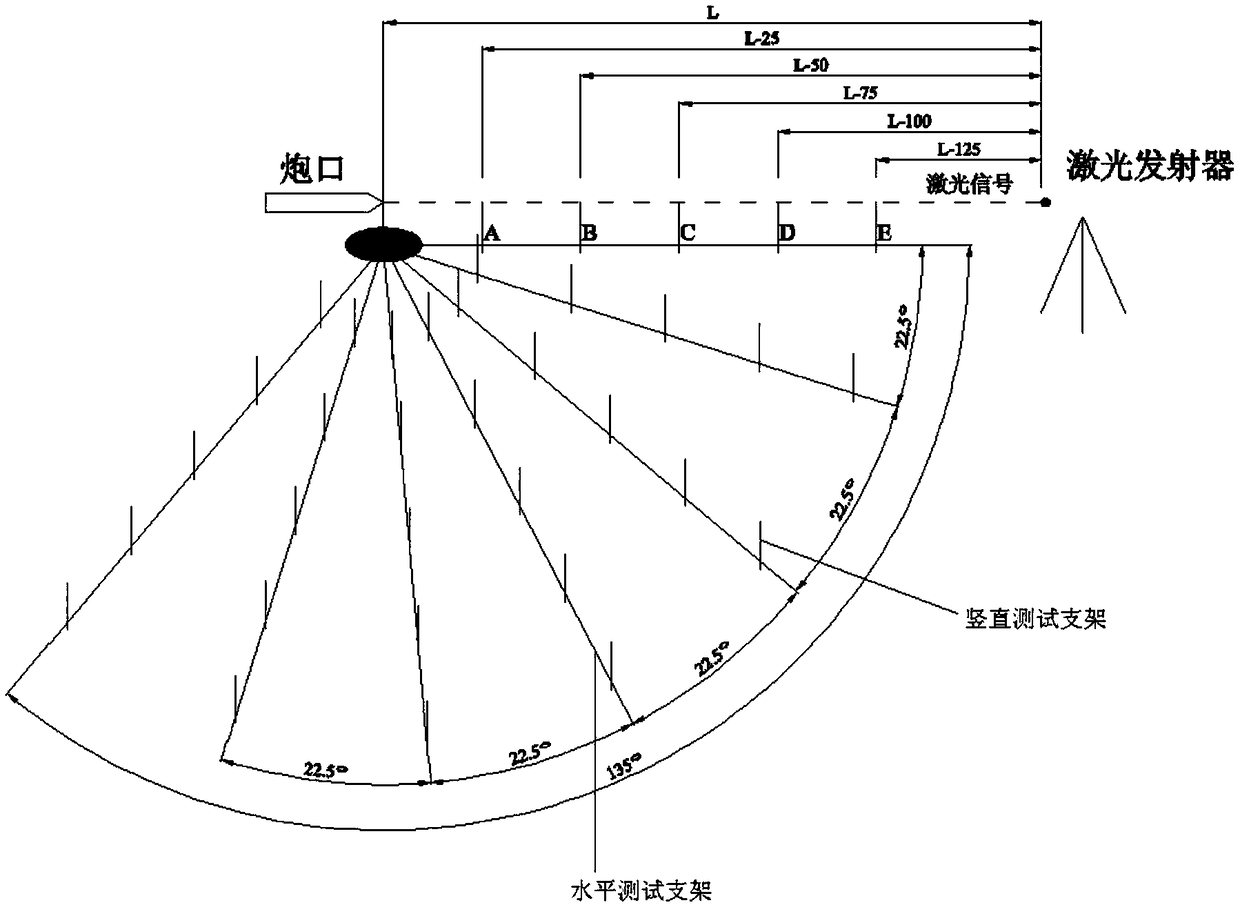

[0023] See Figure 1-Figure 3 , Faced with the arrangement and adjustment of numerous test points, first of all, the installation of the test device is not restricted by the on-site conditions. The position of the vertical support of the test device relative to each angle and the relative muzzle height can reach a consistent height. Thirdly, one person can independently complete on-site location layout and debugging, reduce debugging personnel, reduce personnel measurement errors, improve the uniformity of measurement methods, and improve the accuracy and precision of test data, and then test efficiency.

[0024] In order to overcome the large error of accuracy in the arrangement of the test devices by multiple persons in coordination with each other during the installation and adjustment of the existing test devices, the uniformity of the test devices is poor. The invention provides a rapid deployment method of a multi-dot test device. First of all, the test device is initially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com