An automatic assembly system for pyrotechnics

An assembly system and pyrotechnics technology, which is applied in the manufacture of tools, offensive equipment, manipulators, etc., can solve problems such as operator misoperation, difficulty in ensuring assembly accuracy, and high labor intensity, so as to reduce the possibility of misoperation, The effect of ensuring assembly accuracy and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

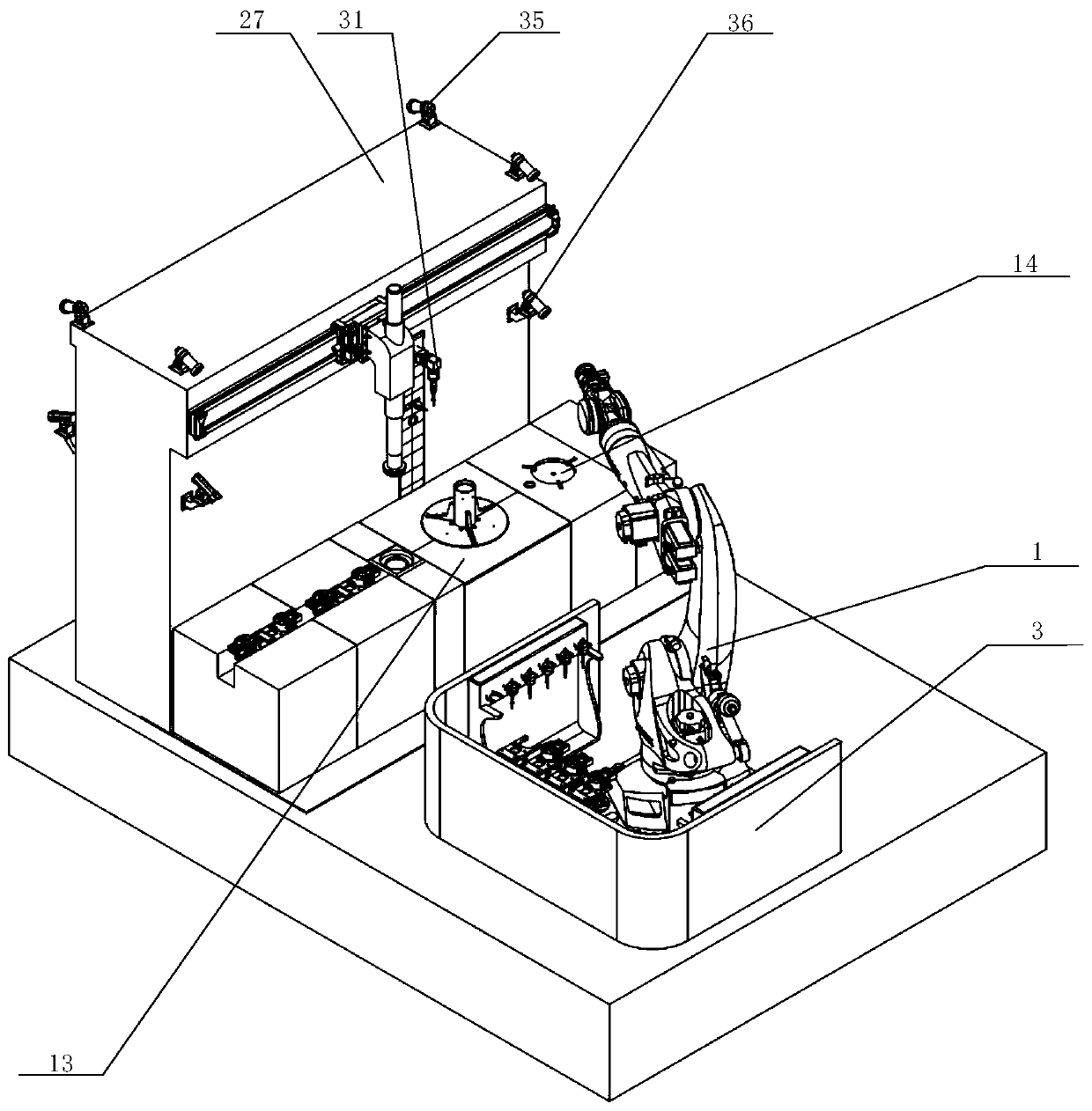

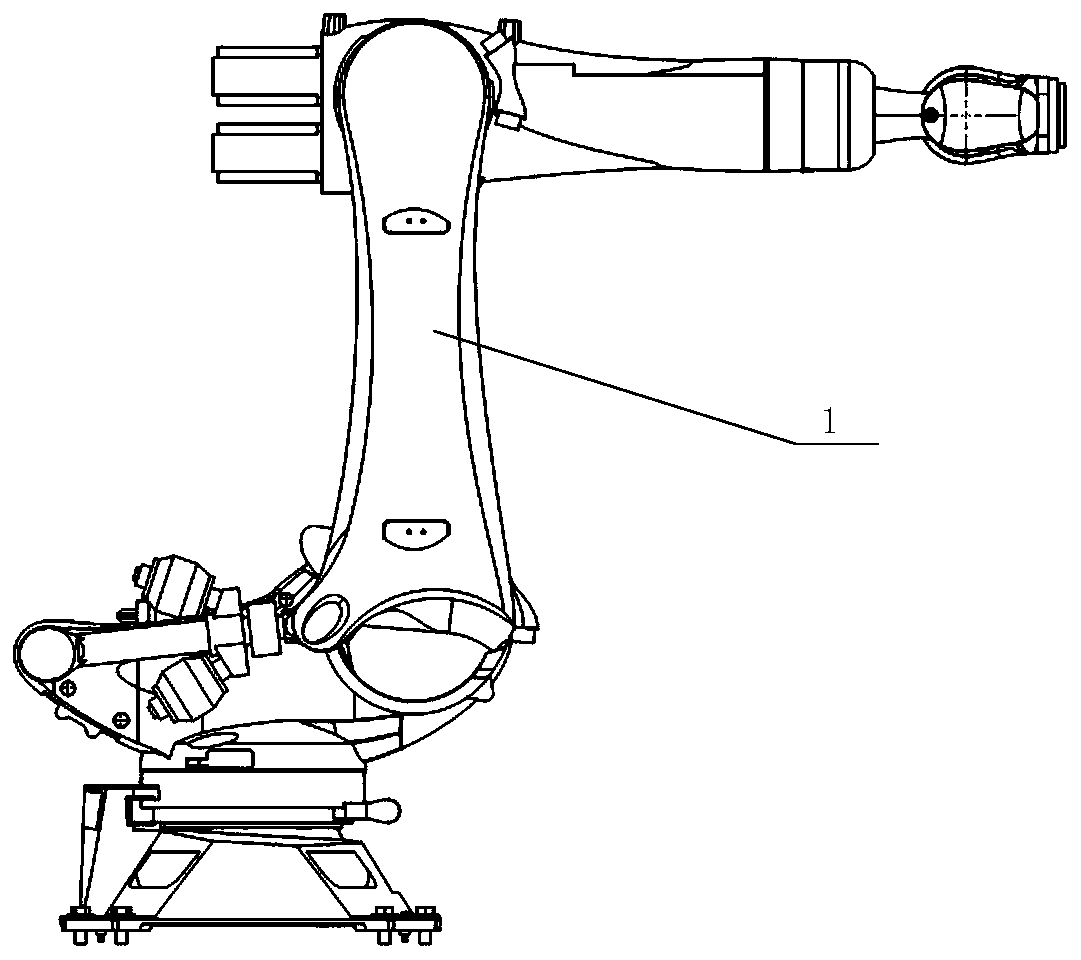

[0038] An automatic assembly system for pyrotechnics, which includes an assembly robot unit, a robot end effector quick-change device unit, a glue filling quick-change device unit, a small assembly table unit, a three-coordinate assembly mechanism unit, and horizontal and vertical directions. Automatic screw screw mechanism and related testing equipment. The assembly robot unit includes an assembly robot for grabbing parts, a vision camera for visual recognition, and a guardrail for isolating the assembly area of pyrotechnics.

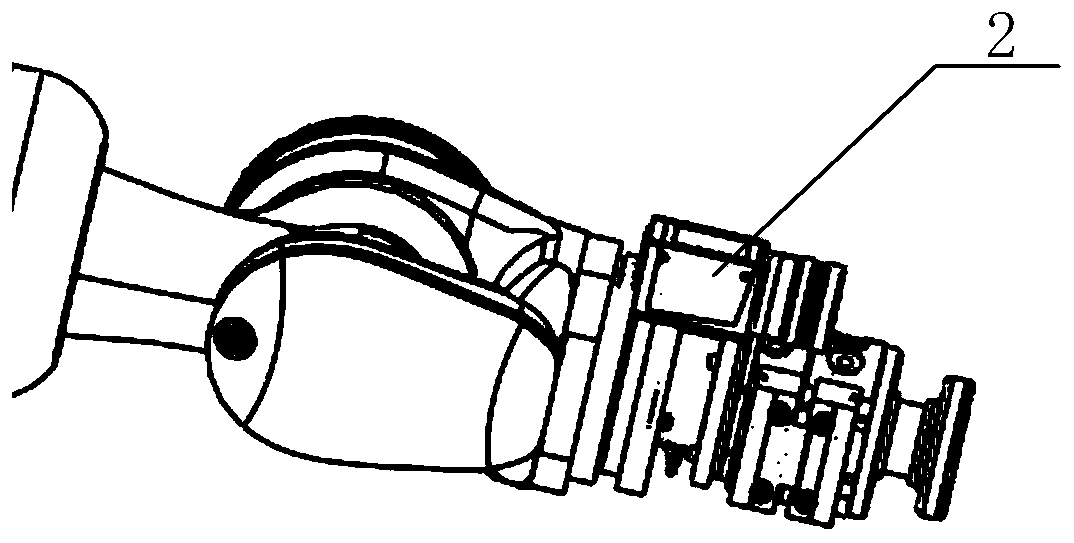

[0039] The robot end-effector quick-change device unit is placed in the middle of the guardrail, including a support frame for placing the end-effector quick-change mechanism, a claw and a photoelectric switch for placing the end-effector, wherein the end-effector includes a suction cup The actuator and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com