Harness tension testing system

A tensile test and wire harness technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem that does not meet the actual measurement needs, has no production and practical application, and cannot be accurately tested. Pulling force value and other issues, to achieve the effect of simple structure, stable work, and improved safety performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0019] Existing tension testing devices are used to test the theoretical maximum tensile force after the wire harness is broken in a physical state. Without any production and practical application, it is impossible to accurately test the real maximum tensile force value of the wire harness in the actual working environment, which is not in line with reality. Measurements required.

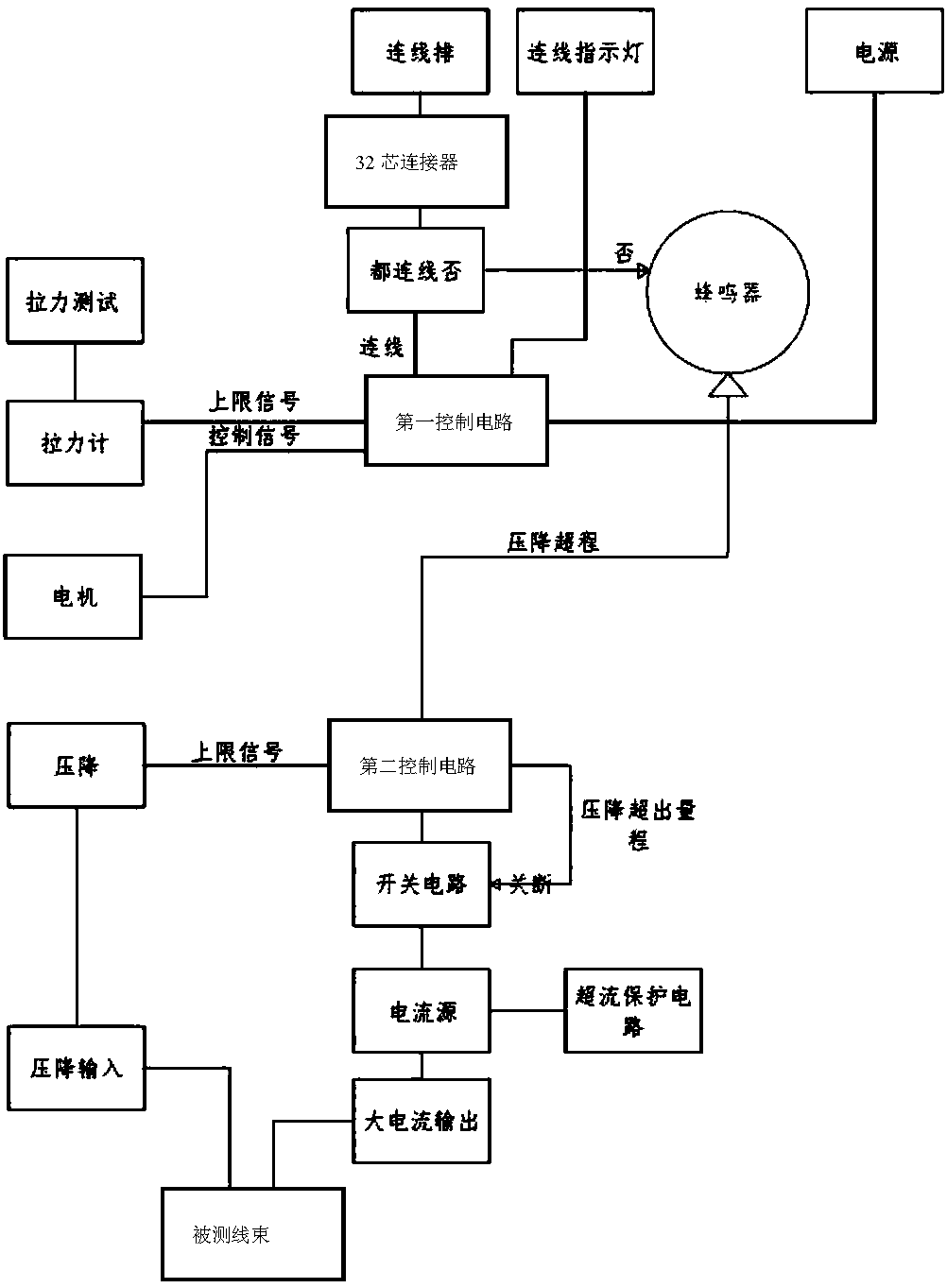

[0020] In view of this, the present invention provides a wire harness pull test system with simple structure, stable operation and high measurement accuracy. The specific structure of the wire harness pull test system is as follows figure 1 As shown, specifically include:

[0021] A first control circuit, a second control circuit, a power supply, a connection indicator light, a tension gauge, a motor, and a harness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com